00:14

00:14

Product Description Item 310S Stainless Steel Round Pipe Grade 300 series, Grade 310S Brand Name TISCO, BAO STEEL, BAOXIN, ZPSS, LISCO, JISCO, etc. Size Outside Diameter 6-630mm Wall Thickness 0.24-30mm Length Less Than 12 Meter Surface Finish Bared, Painted, Galvanized, With Oiled, 3 PE, FBE, corrosion resistant coating Ends Plain, Beveled, Thread with Coupling or cap Technique ERW,EFW DSAW Standard BS EN10296,BS EN10025,BS EN10297,BS6323, BSEN10219,BSEN10217,GB/T13793-1992,GB/T14291-2006, GB/T3091-1993,GB/T3092-1993,GB3640-88,ASTM A53/BS1387 MOQ 1 Metric TON Package Bundle, In Bulk, PE clothes,Clients' Requirements Terms of Delivery FOB,CFR,CIF,CNF,EXWORK Port of Shipment Shanghai Port,China Delivery Time According to the quantity and specification of each order Terms of Payment L/C ,T/T(30% deposit) Packing Standard export sea-worthy packing Stock In stock Chemical Composition Grade C ≤ Si ≤ Mn ≤ P ≤ S ≤ Ni Cr 310S 0.08 0.75 2.00 0.045 0.03 8.00-11.00 18.00-20.00 Physical Property Grade YS (MPa) TS (MPa) Elongtion HRB 310S ≥205 ≥520 5 (%)≥40% ≤90

Wuxi Ginlion Machinery CO., Ltd established in 2010,located in Wuxi Jiangsu Province. Our company mainly work on overseas sales business for special steel and stainless steel. Our products have obtained SGS, ISO9001:2000 approval certificate, QS-9000 : 1998 (American Vehicle Steel Quality System ) approval certificate, and API (American Petroleum Tube Production Quality System) approval certificate. The factory occupies a total area of 500,00 ㎡.Our own factory could also do cutting, bending and welding as your drawing! OEM is always welcomed! We appreciate your coming always!

Contact Supplier 00:46

00:46

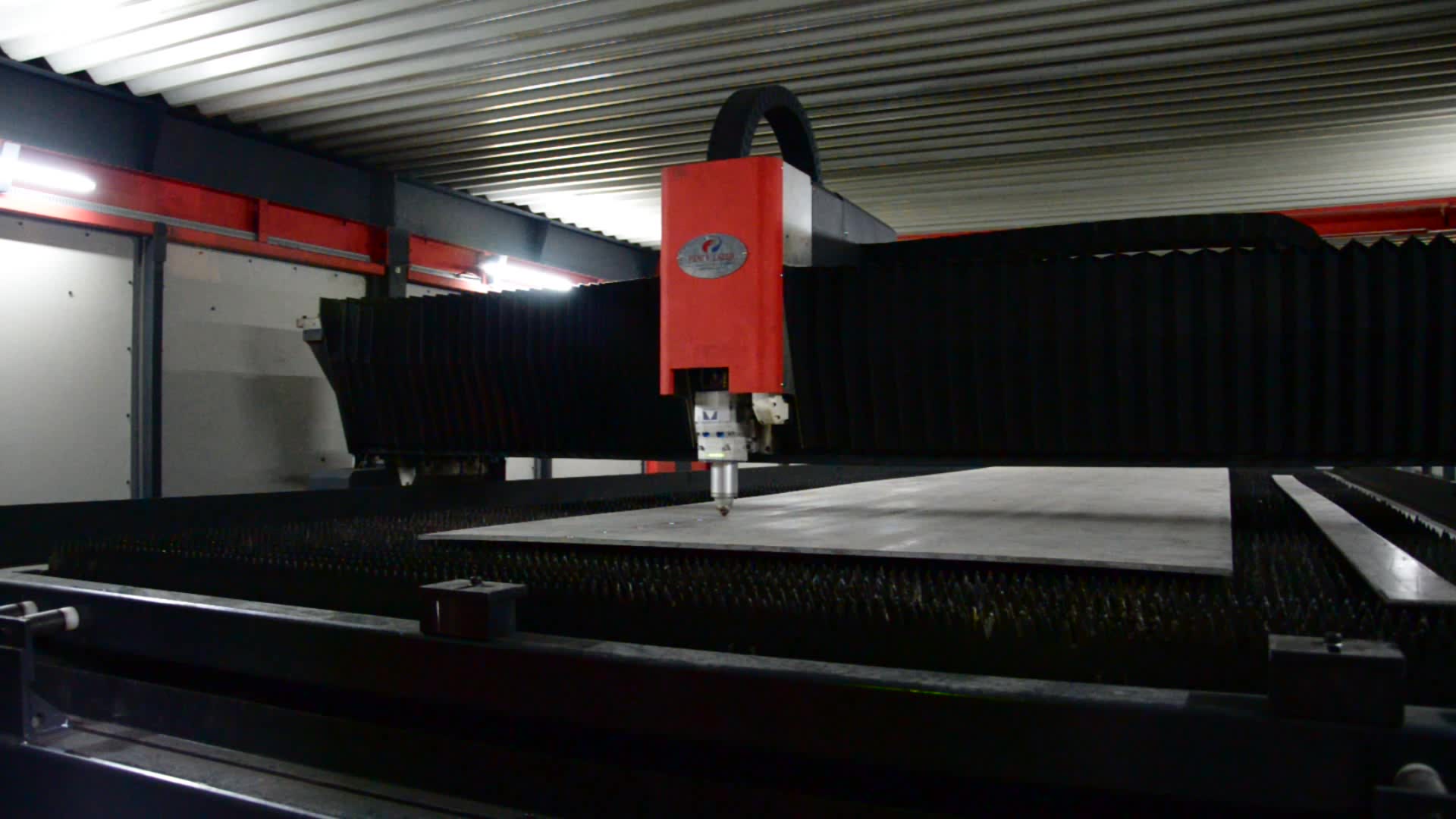

Our secondary processing and finishing facilities allow for low and mid volume metal fabrication, machining, metal finishing and shipping of assembly-ready large fabrications. Project Management & Engineering ●Engineering support ●CAD/CAM systems ●Project management Secondary Machine Processing Capabilities ●Metal Forming ●CNC flame and plasma cutting ●Machine and Blanchard Grinding ●CNC Machining ●Weld stress relieving ●Thermal and vibratory metal stress relieving ●Shot or sand blasting, priming and painting Steel Plate Kits ●Beveling, forming and descaling ●Sequence detail skidding ●Continuous inline shot blaster accommodating 72 ft. wide x 18ft. tall Contract Manufacturing ●Robotic welding for controlled process ●Extensive secondary and finishing capabilities ●In-stock steel inventory

Wuxi Ginlion Machinery CO., Ltd established in 2010,located in Wuxi Jiangsu Province. Our company mainly work on overseas sales business for special steel and stainless steel. Our products have obtained SGS, ISO9001:2000 approval certificate, QS-9000 : 1998 (American Vehicle Steel Quality System ) approval certificate, and API (American Petroleum Tube Production Quality System) approval certificate. The factory occupies a total area of 500,00 ㎡.Our own factory could also do cutting, bending and welding as your drawing! OEM is always welcomed! We appreciate your coming always!

Contact Supplier 00:05

00:05

Falling Film Evaporator Multi-effect falling film evaporation concentration system Technical parameter Falling film evaporator basic working principle The feeding liquid will flow into the tubular falling film evaporator from the upper part of the heater, the feeding liquid flows down along the heater surface by the liquid distributor, By gravity and airflow effect, the feeding liquid flows from top to bottom, and be evaporated. After then the vapor-phase and liquid-phase flow into separator together, The separator will separate the vapor and liquid totally, consequently bring about the secondary vapor and concentrated liquid. For increasing the concentration of the discharging liquid, even avoiding fouling drywall condition, forced circulation falling film evaporator applied in such situation. That's saying to equip forced circulation pump to falling film evaporation system. Evaporator System components Evaporator, separator, condenser, vacuum and discharging system, delivery pump, PLC, electrical appliance and instruments, valves, pipelines etc. Multi-effect evaporation concentration equipment The Live steam as the thermal energy for heating the first effect evaporator then generates secondary vapor which drawn into the second effect evaporator and so on. The multiple evaporators attached to form the whole multiple effect evaporation system. The latent heat will be recycled and reused, thus reducing the energy consumption and enhance thermal efficiency. Features The classic popular evaporation and concentration equipment. As the effects increased, the more vapor energy shall be saved. Lower up-front investment, but a large amount of vapor energy consumption bring about a strong energy consumption intensity. It's suitable to use in low-cost vapor energy field. Friendly to the concentration of thermally sensitive material. Application Range Solution for concentration. Garlic juice concentration. Notice The evaporator is custom-built according to the feeding material and real situation. Contact us for the whole design, manufacture, installation and commissioning issues. Energy consumption Diagram Similar projects

Nomia Machinery Co.,Ltd is professional in manufacturing MVR evaporator, multiple effect evaporator, falling/rising film evaporator, forced-circulation evaporator which are highly specialized of engineering services process design, manufacturing, installation and commissioning. Nomia go through the national high-tech enterprise certification, with the qualification for pressure vessel manufacturing, won ISO9001 quality management system and CE certification for Europe. Nomia machinery owns the first-class highly professional team, technical team, technically advanced manufacturing facilities and a meticulous quality control system, committed to be the respected leading enterprise in evaporation & concentration, continuous evaporation & crystallization, zero liquid discharge of industrial effluents etc. Most important of all, we focus on high efficiency and energy saving.

Contact Supplier 00:05

00:05

The solution for wastewater evaporation and crystallization, brine management, high salinity water treatment, desalination, industrial wastewater treatment etc. System components The Live steam as the thermal energy for heating the first effect evaporator then generates secondary vapor which drawn into the second effect evaporator and so on. The multiple evaporators attached to form the whole multiple effect evaporation system. The latent heat will be recycled and reused, thus reducing the energy consumption and enhance thermal efficiency. Technical parameter Energy Consumption

Nomia Machinery Co.,Ltd is professional in manufacturing MVR evaporator, multiple effect evaporator, falling/rising film evaporator, forced-circulation evaporator which are highly specialized of engineering services process design, manufacturing, installation and commissioning. Nomia go through the national high-tech enterprise certification, with the qualification for pressure vessel manufacturing, won ISO9001 quality management system and CE certification for Europe. Nomia machinery owns the first-class highly professional team, technical team, technically advanced manufacturing facilities and a meticulous quality control system, committed to be the respected leading enterprise in evaporation & concentration, continuous evaporation & crystallization, zero liquid discharge of industrial effluents etc. Most important of all, we focus on high efficiency and energy saving.

Contact Supplier 00:00

00:00

00:00

00:00

00:23

00:23

Product Introduction Product name 310S Stainless Steel Sheet Specification Thickness: Cold rolled: 0.3-3mm; Hot Rolled: 3-120mm Width: 0-2000mm Length: 0-6000mm Customized sizes are accepted Standard ASME, ASTM, EN, BS, GB, DIN, JIS, etc Finish NO.1, NO.4, 2B, BA, HL, 8K, Mirror finish and so on Material 201, 202, 304, 304L, 310S, 316, 316L, 410, 420, 430, 441, 800H, 904L Brand Name TISCO, Baosteel, LISCO, JISCO Place of Origin Jiangsu of China (Mainland) Technical treatment Cold Rolled, Hot Rolled MOQ 1 Metric Ton Port of Loading Shanghai or as your requirement Terms of Delivery FOB, CFR, CIF, CNF, EXWORK Terms of Payment L/C, T/T (30% deposit) Packing Standard export sea-worthy packing Delivery time Within 7-15 days after recieve 30% deposit or as your requirement Stock In stock Chemical Element Grade C ≤ Si ≤ Mn ≤ P ≤ S ≤ Ni Cr 310S 0.08 1.50 2.00 0.045 0.03 19.0-22.0 24.0-26.0 Physical Property Grade YS (MPa) TS (MPa) Elongtion HRB 310S 205 520 40 90

Wuxi Ginlion Machinery CO., Ltd established in 2010,located in Wuxi Jiangsu Province. Our company mainly work on overseas sales business for special steel and stainless steel. Our products have obtained SGS, ISO9001:2000 approval certificate, QS-9000 : 1998 (American Vehicle Steel Quality System ) approval certificate, and API (American Petroleum Tube Production Quality System) approval certificate. The factory occupies a total area of 500,00 ㎡.Our own factory could also do cutting, bending and welding as your drawing! OEM is always welcomed! We appreciate your coming always!

Contact Supplier 00:10

00:10

Product Description Item 316 Welded Stainless Steel Pipe Grade 300 series, Grade 316L Brand Name TISCO, BAO STEEL, BAOXIN, ZPSS, LISCO, JISCO, etc. Size Outside Diameter Customized Wall Thickness 0.3-60mm Length Less Than 12 Meter Surface Finish Bared, Painted, Galvanized, With Oiled, 3 PE, FBE, corrosion resistant coating Ends Plain, Beveled, Thread with Coupling or cap Technique ERW,EFW DSAW Standard BS EN10296,BS EN10025,BS EN10297,BS6323, BSEN10219,BSEN10217,GB/T13793-1992,GB/T14291-2006, GB/T3091-1993,GB/T3092-1993,GB3640-88,ASTM A53/BS1387 MOQ 1 Metric TON Package Bundle, In Bulk, PE clothes,Clients' Requirements Terms of Delivery FOB,CFR,CIF,CNF,EXWORK Port of Shipment Shanghai Port,China Delivery Time According to the quantity and specification of each order Terms of Payment L/C ,T/T(30% deposit) Packing Standard export sea-worthy packing Stock In stock Chemical composition (%) Grade C% Max S% Max Mn% Max P% Max S% Max Cr% Max Ni% Max 316L 0.03 1 2 0.045 0.03 16.0-18.0 12.0-15.0 Physical property Grade YS (MPa) TS (MPa) Elongtion HRB 316L ≥170 ≥485 ≥30 ≤90

Wuxi Ginlion Machinery CO., Ltd established in 2010,located in Wuxi Jiangsu Province. Our company mainly work on overseas sales business for special steel and stainless steel. Our products have obtained SGS, ISO9001:2000 approval certificate, QS-9000 : 1998 (American Vehicle Steel Quality System ) approval certificate, and API (American Petroleum Tube Production Quality System) approval certificate. The factory occupies a total area of 500,00 ㎡.Our own factory could also do cutting, bending and welding as your drawing! OEM is always welcomed! We appreciate your coming always!

Contact Supplier 01:45

01:45

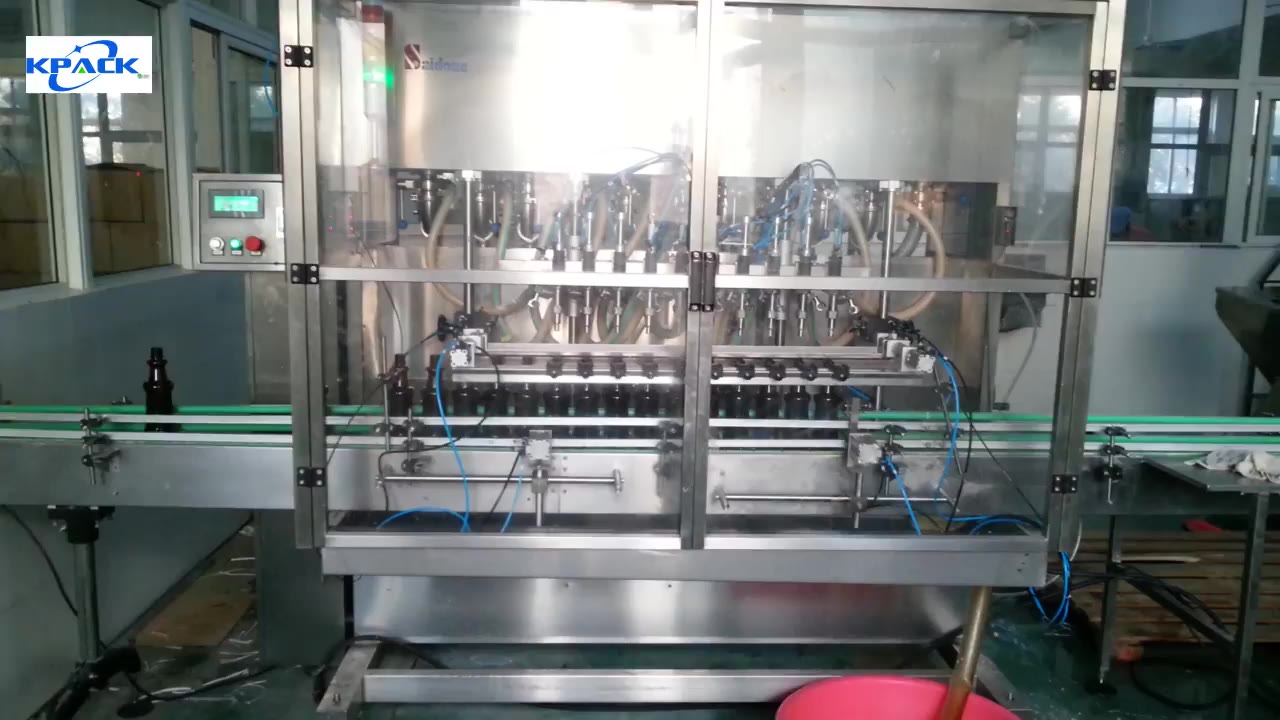

Tank finishing Empty tank sterilization Mixing Vibration screwing feeding Automatic positioning quantitative feeding Tank sealing

Shanghai kunbu packaging Machinery Co.,Ltd .Is collection of research and development , manufacturing ,sale and service in the integration of automatic packaging machinery .We Specialized in Snacks food , biscuit ,powder , nut ,liquid , paste and frozen food ,agricultural chemical products and automatic packaging conveyor system .Our machines are exported to Europe, America, Southeast Asia, the Middle East, Russia and the surrounding more than and 50 countries .

Contact Supplier 00:03

00:03

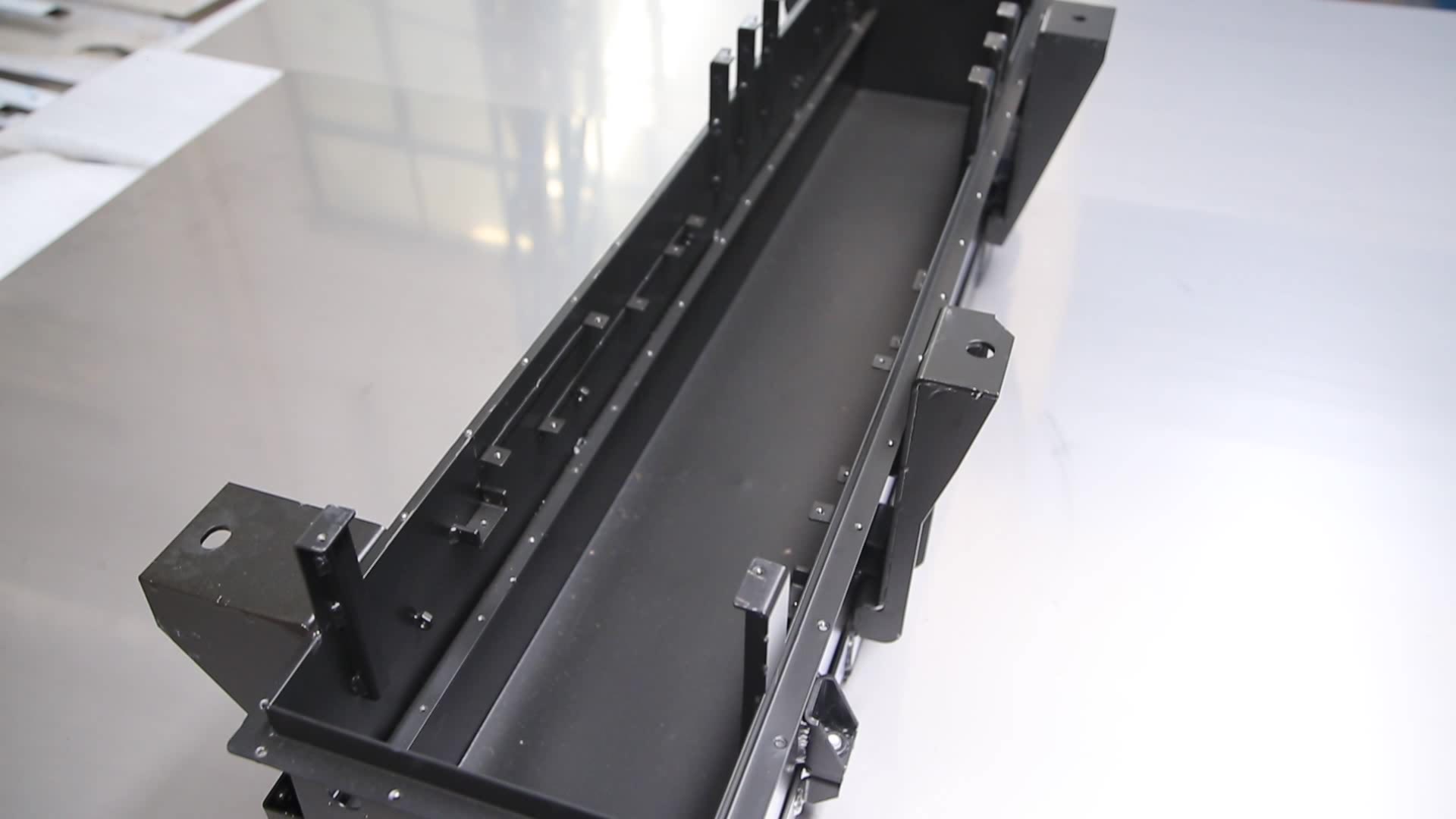

Material:Q235*1.5mm Process Technology:Laser cuttinging→stamping→bending→welding→painting

King’s Sung Co.,Ltd. established in Taipei of Taiwan province in 1980. In initial stage we mainly processed the relevant sheet metal products for the elevator, while gradually expanding the processing scope of sheet metal products and also developing the relevant products, from designing to manufacturing. Now we mainly process sheet metal parts for the industrial air conditioner, home electrical appliances and construction material. “Negotiating with clients constantly& researching and developing together” is our tenet. Furthermore, we expanded the business scope to Shanghai in 2003,and then established Sharp Century Metal Products (Shanghai)Co.,Ltd. Sharp Century Metal Products (Shanghai)Co.,Ltd is located in Jiading District of Shanghai, which is a well-known modern comprehensive steel service enterprise specializing in processing, sales and technical services of stainless steel and carbon steel. SC possesses the world first-class steel processing equipments, modern management concept and exquisite processing technic “shearing, cutting, bending, welding, etc ”.Total architectural area is 11000 square meters(The headquarters is 7000 square meters, the branch is 4000 square meters). We are committed to process innovation and high efficiency production all the time. During the initial stage of our company establishment, SC has passed ISO9001-2000 certification,EN15085-2 and ISO3834 followed successively. SC manage company strictly according to requirements of quality system.With abundant experience, professional standards and proven technique from metal fabrication in Taiwan, SC developed steadily in the field of sheet metal fabrication. During the development we import advanced equipment and technology, exchange with customers continuously. At present SC has 3 IWE, 8 R&D engineers, more than 30 ISO9606-1 certified welders. In order to expand production,SC built a new plant in Songjiang in 2009 specializing in manufacturing stainless steel equipment, our major industry contains track locomotive, nuclear power equipment and oil and petrochemical industry. At this period full of challenges and opportunities,SC adhere to market-oriented, with talent as a fundamental, with technology as a support, taking capital as bond,we dedicated to crate a international enterprise with core competitive power.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery

00:00

00:00

00:00

00:00