01:30

01:30

Overview The rolling capping machinecan cap different sizes and shapes of lids, the capping height of the machine can be adjusted to fit your machine. The machine is made of stainless steel of 304, meeting with CE standard and GMP standard, can be used in food, medicine. It can be connected with filling machine and labeling machine. The machine adopts PLC control, it’s easy operate.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:27

00:27

Overview The bottle washing machine is a custom-made machine based on the customer's sample and requirements. It is solely designed and produced by our company Features 1、Special equipment for cleaning empty bottles。 2、Scientific & Humanize design, perfect control system. Easy operation 3、Wash with spray water and air drying; 4、Change bottle type, simple and quick.Only by start wheel & guide plate Applications This machine is suitable for the production of bottled drinks, mineral water, fruit juice, condiments, Coca Cola, oral liquid and other industries, cleaning glass bottles. This machine can be used by large and medium-sized manufacturers, and can be used in the filling system and other equipment to form an efficient automatic production line.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:00

00:00

The palletizing robot has a wide range of applications, small footprint, reliable performance and easy operation. Although it is compact, it can be integrated into a compact packaging machine, but it can meet all your requirements for distance and payload. Coupled with motion control and tracking performance, the robot is ideally suited for flexible packaging systems, greatly reducing packaging cycle times. Extremely accurate, coupled with superior belt tracking performance, both in fixed position and in motion, the pick and place accuracy is first rate. Small in size and fast, it is optimized for packaging applications. Equipped with a full set of auxiliary equipment (from integrated air and signal system to the gripper), it can be used with packaging software. The mechanical integration is simple and the programming is very convenient. The state-of-the-art 4-axis, 6-axis design, high-speed robot with a maximum reach of 3.15m and a payload of 250kg, suitable for harsh environments with IP 67 protection. The versatility, reach and load-bearing capacity of the robot can meet almost any boxing application. The replacement of the gripper can be applied to the automatic packing of various products in the chemical, pharmaceutical, salt, food, sugar, beverage and other industries.

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier 02:28

02:28

Product Description This machine is applicable for Round Shaped Tinplate can , Aluminum Can or PET can seaming with vacuuming and nitrogen filling processes. Technical Parameters 1) Seaming Speed: 10 cans / minutes 2) Size range of can: Diameter: 70-127mm, Height: 80-190mm 3) Power requirement: 380V, 50/60HZ, 4) Power Capacity: 4.0 Kw 5) Net Weight: 500kg 6) Dimension: 2000(L)×800(W)×1850(H)mm 7) Compressing Air Requirement: 0.6-0.8MPa 8) Compressing Air Consumption: 80Liter/Min 9) Nitrogen Pressure: >=0.4Mpa 10) Nitrogen Consumption: App. 50 Liter/Min 11) Residual oxygen content: <=5% 12) Vacuuming Pump: Include 13) Filter Tank: Include, Stainless Steel 304

Shanghai Shouda Packaging Machinery & Material Co., Ltd. is a professional manufacturer of automatic packaging machineries & automatic filling and packing production line for liquid, gel, aerosol

Contact Supplier 00:00

00:00

Overview This metering pump filling machine is specially made for all viscous materials, such as water, gel, shampoo, oil etc. The machine adopts piston pump and for filling. By adjusting the position pump, it can fill all of the bottles in one filling machine, with quick speed and high precision. Feature 1. Adopts piston pump to fill, suitable for all kinds of liquid, high precision; The structure of pump adopts shortcut dismantling organ, convenient to wash, sterilize. 2. The piston ring of volumetric injection pump use different material of silicone, polyclonal or other kinds according to liquid characteristic, use ceramic pump in special industry. 3. PLC control system, frequency conversion adjusting speed, high degree automation. 4. No bottle, no filling, auto count the quantity. And have the anti-drop device. 5. Filling quantity of all pumps is adjusted in a lump, minim adjustable for each pump. Easy and quick operate. 6. Filling head is equipped with anti-dropping equipment, diving to the bottom to fill, rise slowly, to avoid bubble. 7. The whole honey bottle filling machine is suitable bottles in different size, easy adjusting, and can be finished in short time. 8. The whole machine meets GMP requirement. After sale service (1) Long life service (2) One year warranty (3) Offering free parts for one year . (4) Engnieers available to service machinery overseas

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:25

00:25

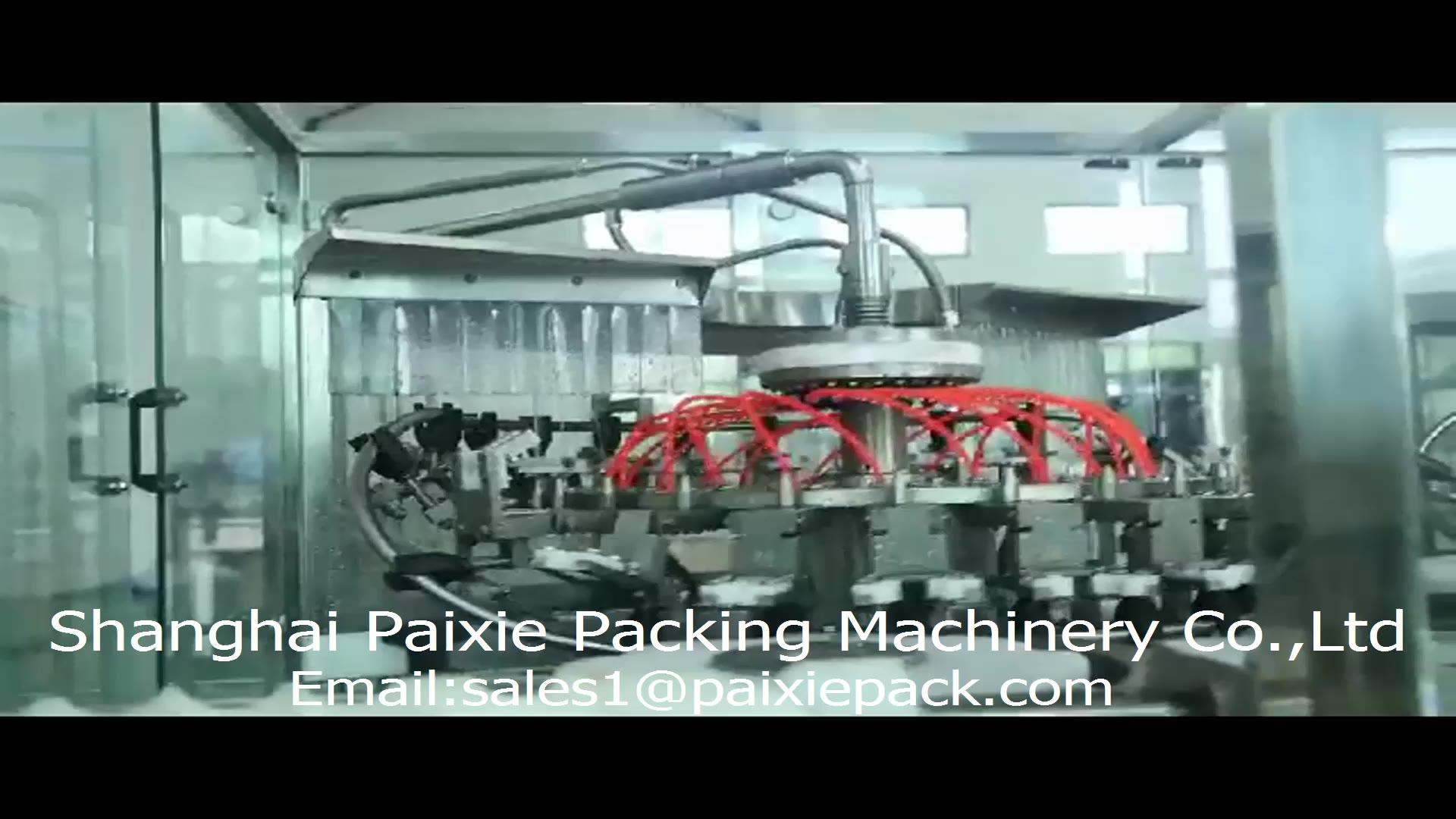

The rinser filler capper 3 in 1 machine is for fill light liquid. It can carry washing filling capping in one machine. It can be used alone or connected with other machines. It can connect with bottle unscrambler, or air conveyor, cap elevator ,labeling machine and so on. The rinsing, filling and capping process will be carried out using a continuous system in a fully enclosed safety interlocked chamber using our years of experience and the latest technology. Features (1)The all machine applies bottle handling technical and the filling valves go up-down when filling, which make sure the bottle filling goes stable, reliable during high speed. The bottle handling technical also make the different bottle changing easily without changing too many accessories. (2) This machine uses new generation stainless steel spring washing clips and the clips do not contact the upside of bottle screw avoiding the second pollution. It can both clear the inside and the outside of the bottle. (3) The advanced normal pressure filling principle was applied. Filling is quick, and stable. Not contacting with the liquid avoids second pollution and oxidation. (4) Magnetic torque is used for screw capping, and the power of screw capping can be adjusted steplessly. Capping is reliable and do no harm to the caps. (5) Advanced technologies, such as human-machine interface touch-screen and PLC program control are adopted in this machine. (6) All parts that have direct contact with the water are made of high quality stainless steel. The critical electrical components are from famous international companies, such as Mitsubishi, Omron to name a few.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 01:58

01:58

Brief introduction: The bottle caps neatened by the cap neatening device ,the bottle caps with mouth up are carried to the caps collecting guideway, the bottles come from other equipment of the assembly line enter the caps collecting area. The bottles move ahead with clamping of the two sides clamping device then the caps match the bottles automatically. The cap pressing device presses the caps to the pre-tight situation before rotating the caps. Under the function of three pairs of high speed rotating wearable rubber wheels, the caps match with the bottles tightly. Main parameter: Bottle height Φ20-φ250mm Capping size Φ20mm~Φ130mm(the shute is customized) Conveying direction Left-right(or right-left) Capacity 30-50bottles/min Powder supply 220V 50-60Hz Power 1300W Weight 450kg Dimension 1500mm×1000mm×1800mm

Shanghai Shouda Packaging Machinery & Material Co., Ltd. is a professional manufacturer of automatic packaging machineries & automatic filling and packing production line for liquid, gel, aerosol

Contact Supplier 01:42

01:42

Overview The machine is suitable for round bottle and flat bottle. Can fill syrup, lipometric etc. SUS304 stainless steel piston pump volumetric filling, with high filling precision, stable working and easy operation etc; meet GMP requirement. The machine take bottles to the turn table by conveyor, the board on the table take bottles into each station, then fill, insert valve, screw cap and there is approaching switch in each station, checking position signal and carry on different operation. The line through electricity, pneumatic and mechanism to realize the above work. Main parts:(1)rack (2)filling nozzle (3)measuring pump group (4)conveyor (5) motor(6)filling nozzle elevator (7)turntable (8)Nylon pipe (9) photoelectrical detector (10) valve(11) one-way valve (12) slicer (13) vibration plate (14) vibrator (15) rail (16) lamp stand etc. Main technical parameter: Capacity: 25-30b/min Filling way: peristaltic pump dosing filling Nozzle: 1 heads Filling precision: ±0.5% Way to put valve: automatic Cap percent of pass: ≥99% Stand-lone noise: ≤50dB Power: 1.7kw Weight: 650kg Round bottle labeling machine Overview: Model SD-LTB-A Vertical Labeler for round bottle is mainly used in food, chemical and medicine industry. It can realize the automatic bottle-conveying, label separating, labeling round the bottle and a series of steps. Step-less speed adjustment, easy operation and adjustment with high speed and efficiency. The label will be attached to the exact position with high accuracy and low noise. The spare parts can be matched by customer’s specific requirement Model SD-LTB-A Vertical labeler for round bottles Capacity 80~100 BPM Bottle Size(mm) To be confirmed Machine dimension(mm) 1600×960×1260 Weight(kg) 200 Power(w) 300 Voltage 220V / 50~60Hz (customized)

Shanghai Shouda Packaging Machinery & Material Co., Ltd. is a professional manufacturer of automatic packaging machineries & automatic filling and packing production line for liquid, gel, aerosol

Contact Supplier 01:19

01:19

Overview Automate bottle filling capping for small bottles , it is a high performance compact piston pump liquid filling machine and can be customized. We also can equip the peristaltic pump for filling. The system aseptically and precisely fills liquid to small bottles. An optional diving nozzle mechanism plunges the filling nozzles into the container for increased production speeds without splashing, and we can produce the different filing nozzles for your different speed requirement. Filling volumes are programmable and can be adjusted from the touch screen. Characteristics ● It is applicable to different-shaped bottles and plastic bottles: PP , PE , PVC ,glass bottle and mould bottle. ● The bottle-in and bottle-out has specialized structure .It doesn't drop bottles or nip bottles ● The part which touches the liquid medicine is made of SS304 stainless material completely, meeting the requirement of CE GMP. ● It can be connected with the bottle-washing machine and the label-attaching machine to form a complete set of produce line.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:00

00:00

The palletizer is to put the cartons, barrels, bags, etc., which have been loaded into the container, on a pallet according to a certain arrangement code.,automatically having layers of pelletizes, then launch for a convenient fork working to warehouse.the machine adopt PLC + touch screen control, realizing an Intelligent and easy operation. It can largely induce the labor intensity. The touch screen operation is used to realize man-machine dialogue, which can display the production speed, the cause and location of the fault, and the degree of automation is high. The PLC stacking ordering stacking number, pallet supply and discharge can be programmed into the program for control. Using pneumatic components and cylinders produced by Taiwan Airtac, the quality and performance are reliable. The safety door and the cover are provided with electrical induction devices. When the cover door is opened, the machine stops working and the operators can be protected. The stacking method is easy and simple to adjust, and can be performed on the touch screen. Stacking is stable and efficient, which can save manpower. The carton supply system is controlled by a brake motor to ensure that the carton is transported in a pre-set position. The pallet library has a large capacity and can accommodate 10-12 empty pallets, which can realize automatic supply of pallets. The noise is small and meets the international standard of China, and the noise is below 75db. Several stacking methods can be completed without replacing the stacking parts.

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier 00:00

00:00

Summary The YG series equipment is mainly used for the filling production of liquid . It is composed of auto-bottle settling machine, piston pump filling machine, capping machine, labelling, aluminum foil clapper, PE film shrink wrapping machine. This machine is very suitable for the production of those liquid and ointment products. Principles and characteristics 1. SD-YG series filling machine is developed by our company, suitable for filling a series of high concentrations of fluids. It is through SERVO MOTOR to drive a piston and transfer--valve’s Three Contacts principle to extract and to split out the highly concentrated material, and by magnetism-reed switch to control air cylinder’s travel, then can adjust the filling volume. 2. This device is simple and reasonable in structure, easy to understand, with high accuracy. 3. Pneumatic part adopts Taiwan Airtec pneumatic components. All part contacted with material is 316L stainless steel. 4. Filling volume and filling speed can be arbitrarily adjusted with high filling accuracy. 5. Filling head adopts anti-drip, anti-drawing and lifting devices. 6. meet GMP standard Specifications Filling speed: 5000-6000b/h(can customized) Filling range: 125, 200, 300, 700ml (can customized) Filling precision: ≦±1﹪ Current: 16A Voltage: 220/110V 50/60Hz Power: <2.5kW Pressure: 0.4-0.6MPa Machine Size: 2100*1500*2000mm (for reference only)

Shanghai Shouda Packaging Machinery & Material Co., Ltd. is a professional manufacturer of automatic packaging machineries & automatic filling and packing production line for liquid, gel, aerosol

Contact Supplier 00:00

00:00

The machine can finishing measuring, filling etc. because of original design, it is more suitable for packing powdered material that is easy to flow, like veterinary drug, sugar, glucose, carbon dust, talcum powder, essence etc. Except motor, the shell of the whole machine is 304 stainless steel, and the powder contact part is SS 316.combined transparent work bin, easy to dismantle without tools. Adopts servo motor to drive auger, with the advantages of durable, accurate location, stable function etc. the machine is controlled by PLC, with stable working, anti-distraction, high filling precision etc. Parameter: 1.Production capacity: 20-25 b/min 2.Filling head: 1 3.Applicable specification: customized 4.Filling error:≤±2% 5.Voltage:380v/50HZ 6.Power:2.2kw 7.Dimension: 1200*1200*1700mm 8.Weight: 600kg

Shanghai Shouda Packaging Machinery & Material Co., Ltd. is a professional manufacturer of automatic packaging machineries & automatic filling and packing production line for liquid, gel, aerosol

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery