Biomass Ring Die Pellet Mill

Description

What is biomass pellet mill?

Biomass pellet mill, also called biomass granulator, is a kind of pellet mill producing biomass pellets. Biomass pellets fuel is a new environmentally friendly renewable resource. Biomass pellets making machine is a high efficient machine to make waste materials into solid fuel. YUDA Machinery is specialized in manufacturing series biomass machinery, biomass pellet machine, biomass ring die pellet mill, biomass pellet granulator, biomass fuels pellet machine, wood pellet mill, etc.

Main parameters of ring die biomass pellet mill:

Model information

capacity:0.6-1t/h

product:sawdust、rice husk pellet

main motor power: 45kw

feeding screw motor power: 2.3kw

pellet forming rate: ≥95%

pellet powder rate:≤5%

noise:≤85dB(A)

Dimensions:1800*1300*1150

Weight: 1.7 T

Characters of ring die biomass pellet mill:

Application: biomass particle making machine

Type: ring die wood pellet mill

Pellet forming rate: ≥98%

Material: stainless steel

Description of ring die biomass pellet mill:

1. MZLH(L) series ring die biomass pellet mill is a kind of ring die pellet mills for producing hard particles. This ring die biomass pellet mill applies to all biomass pellets manufacturing enterprises.

2. Possessing these features of compact structure, good appearance, high capacity, low power consumption, convenient to use and reliable working, etc.

3. This ring die biomass pellet mill is equipped with ring die of Φ5-Ф9 die hole, depending on customers’ needs. And the ring die can also be customized.

4. This biomass pellet mill using frequency conversion motor to feeding, with overload protection device, gasoline pump and lubricating system.

5. Applies to small and medium biomass pellets enterprises. This series of biomass pellet mill is convenient to operate, with small investment and high efficiency.

6. Patent No.:201420623743.X

Biomass pellet mill, also called biomass granulator, is a kind of pellet mill producing biomass pellets. Biomass pellets fuel is a new environmentally friendly renewable resource. Biomass pellets making machine is a high efficient machine to make waste materials into solid fuel. YUDA Machinery is specialized in manufacturing series biomass machinery, biomass pellet machine, biomass ring die pellet mill, biomass pellet granulator, biomass fuels pellet machine, wood pellet mill, etc.

Main parameters of ring die biomass pellet mill:

| Model | Power | Ring die | I.D of Die | Product | Capacity | Forming rate | Noise |

|---|---|---|---|---|---|---|---|

| MZLH (L)470 | 37-45KW | 8-10mm | 470mm | Biomass pellet | 0.7-1.2t/h | >98% | <80 |

| MZLH (L)508 | 45-55KW | 8-10mm | 508mm | Biomass pellet | 1-1.5t/h | >98% | <80 |

Model information

capacity:0.6-1t/h

product:sawdust、rice husk pellet

main motor power: 45kw

feeding screw motor power: 2.3kw

pellet forming rate: ≥95%

pellet powder rate:≤5%

noise:≤85dB(A)

Dimensions:1800*1300*1150

Weight: 1.7 T

Characters of ring die biomass pellet mill:

Application: biomass particle making machine

Type: ring die wood pellet mill

Pellet forming rate: ≥98%

Material: stainless steel

Description of ring die biomass pellet mill:

1. MZLH(L) series ring die biomass pellet mill is a kind of ring die pellet mills for producing hard particles. This ring die biomass pellet mill applies to all biomass pellets manufacturing enterprises.

2. Possessing these features of compact structure, good appearance, high capacity, low power consumption, convenient to use and reliable working, etc.

3. This ring die biomass pellet mill is equipped with ring die of Φ5-Ф9 die hole, depending on customers’ needs. And the ring die can also be customized.

4. This biomass pellet mill using frequency conversion motor to feeding, with overload protection device, gasoline pump and lubricating system.

5. Applies to small and medium biomass pellets enterprises. This series of biomass pellet mill is convenient to operate, with small investment and high efficiency.

6. Patent No.:201420623743.X

-

Details

-

Finished biomass pellets

-

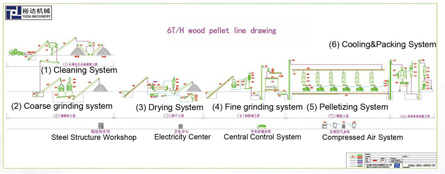

Design flowing map

-

Packing

-

Biomass project

-

Certifications

TOP