C Channel Roll Forming Machine

2

Share

TECHNICAL PARAMETER

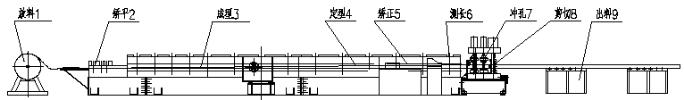

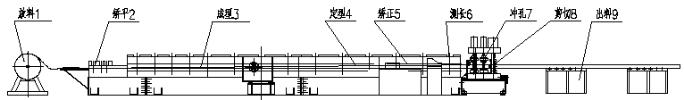

FLOW CHART

FLOW CHART

APPLICATION

APPLICATION

You can manufacture four type of C purlin by one machine through change the blades

Capability feature:

1)Base of machine is processed by gantry process centre and the locating pin of screw connects wall of machine stand. Panel can be formed with straightness, which guarantees the high accuracy.

2)Adopts hydraulic interlaced cutting which makes sure of the exact geometrical profile of formed panel. This cutting method causes no waste material.

3)Adopts computer for measuring of length. Two sides of C purlin have been punched with elliptical holes and the distance between holes can be adjustable. The bracing holes are punched in the middle of purlin.

Equipment includes:

Manual un-coiler:

1) Un-coiler: umbrella type

2) Load capacity of un-coiler: 5T

3) Un-powered

4) Coil width: max 625mm

5) Coil inter-diameter: 508-610mm

6) Coil thickness : 1.5-3.0mm

Main roll forming machine:

1) Arranges with leveling unit of 7 rollers, which assures the levelness of C purlin, with feeding guide.

2)Material of roller adopts high-quality alloyed GCR15.

3)Heat treatment: forging—temper—anneal—normalizing—quenching—temper

4)Whole specifications according to” C purlin profile and size”

5)Diameter of roller shaft: Φ70㎜

6)The whole production line is 20 m

7)Forming speed: 0-15m/min

8)Quenching hardness of roller: HRC58-60

9)Quenching deepness of roller: 8mm

10) Drive mode: hydraulic motor

11) Transmission: 20A chain

12) Wall-plate-frame-design

13)Roller station: 14 stations

Hydraulic punching device:

1)Stop to Punching

2)Two units of punching station, one for one for double holes, another for single hole, the holes type are according to customer’s request.

3)Punching material: Cr12 heat treatment.

4)Connecting holes for installation are adjustable.

Hydraulic cutting device:

1)Stop to cut.

2)Blades material: Cr12 heat treatment.

3)Total sets of blades: 4 sets for 4 size C purlin

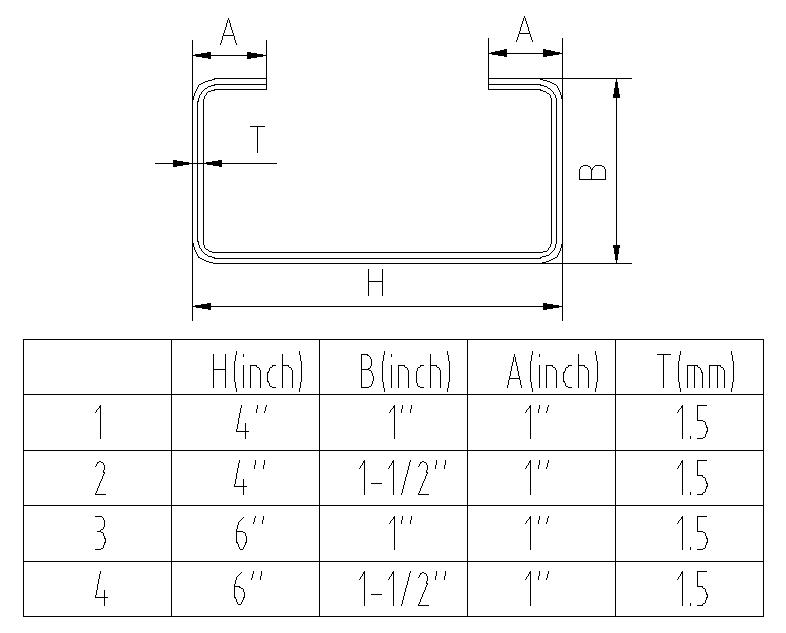

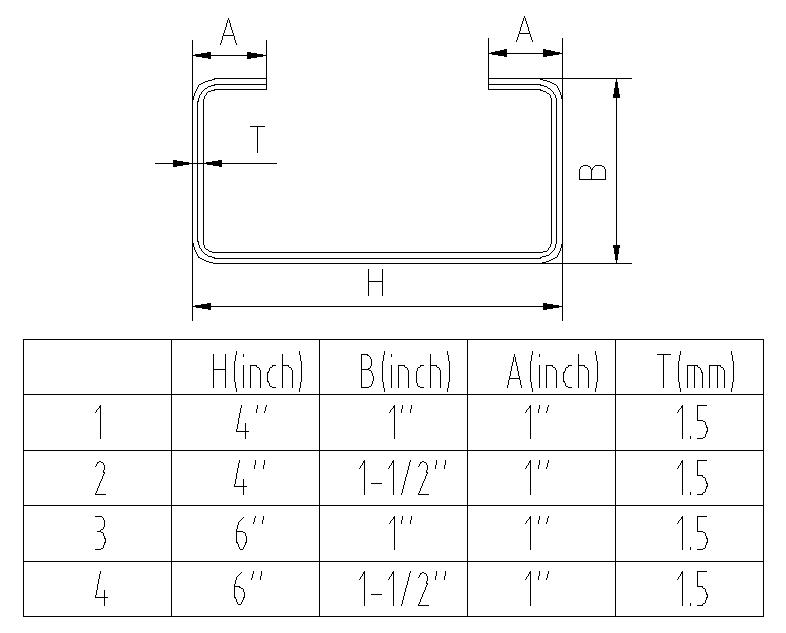

PROFILE

Capability feature:

1)Base of machine is processed by gantry process centre and the locating pin of screw connects wall of machine stand. Panel can be formed with straightness, which guarantees the high accuracy.

2)Adopts hydraulic interlaced cutting which makes sure of the exact geometrical profile of formed panel. This cutting method causes no waste material.

3)Adopts computer for measuring of length. Two sides of C purlin have been punched with elliptical holes and the distance between holes can be adjustable. The bracing holes are punched in the middle of purlin.

Equipment includes:

Manual un-coiler:

1) Un-coiler: umbrella type

2) Load capacity of un-coiler: 5T

3) Un-powered

4) Coil width: max 625mm

5) Coil inter-diameter: 508-610mm

6) Coil thickness : 1.5-3.0mm

Main roll forming machine:

1) Arranges with leveling unit of 7 rollers, which assures the levelness of C purlin, with feeding guide.

2)Material of roller adopts high-quality alloyed GCR15.

3)Heat treatment: forging—temper—anneal—normalizing—quenching—temper

4)Whole specifications according to” C purlin profile and size”

5)Diameter of roller shaft: Φ70㎜

6)The whole production line is 20 m

7)Forming speed: 0-15m/min

8)Quenching hardness of roller: HRC58-60

9)Quenching deepness of roller: 8mm

10) Drive mode: hydraulic motor

11) Transmission: 20A chain

12) Wall-plate-frame-design

13)Roller station: 14 stations

Hydraulic punching device:

1)Stop to Punching

2)Two units of punching station, one for one for double holes, another for single hole, the holes type are according to customer’s request.

3)Punching material: Cr12 heat treatment.

4)Connecting holes for installation are adjustable.

Hydraulic cutting device:

1)Stop to cut.

2)Blades material: Cr12 heat treatment.

3)Total sets of blades: 4 sets for 4 size C purlin

Products

- Continuous Sandwich Panel Production Line

- Discontinuous Sandwich Panel Production Iine

-

Roll Forming Machine

- Roof & Wall & Door Sheet Roll Forming Machine

- Deck Floor Roll Forming Machine

- C & Z Purlin Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Downpipe Roll Forming Machine

- Box Beam Roll Forming Machine

- Folding, Shearing & Bending Machines

- Steel Springboard Roll Forming Machine

- Steel Sheet Pile Roll Forming Machine

- No-girder And Columniation Curve Roll Forming Machine

- Slitting & Cut to length line

- PU Raw Material

TOP