FBU double cartridge seal 2240

Double-balanced design, ultimate reliability

Typical applications:

The double-balanced design of 2240 ensures reliable and long-lasting operation under the most demanding conditions. This seal is typically used in pumps for abrasive and environmentally hazardous liquids in pulp and paper mills. Applications include also demanding services in food, metal and fertilizer processes.

The 2240 seal is especially designed for the Sulzer AHLSTARUP pump series.

Features and benefits:

• Seal utilizes the integrated and advanced SmartFlow seal water control technology.

• More than 90% seal water savings compared to normal flow control system.

• Single spring located in the stationary part of the seal. Material is corrosion resistant and flushed with seal water.

• Shaft misalignment does not pulsate the spring nor wear out the O-ring.

• Heat shrunk SSiC/SSiC, seal faces as standard materials.

• The piston design of the seal enables large axial movement that does not have impact on spring loading.

• No measurements required for installation. Easy installation reduces risk of human error.

• Seal installation does not require back plate removal and the seal is fastened with one bolt which guarantees fast trouble free installation.

• Torque transmission with super elastic devices combined with no drive pins at seals faces. This eliminates possible start-up failures.

• Even in standard models, PTFE is used in O-ring positions where they are exposed to the process liquid.

• The special double-balanced design allows the use of both pressurized and non-pressurized sealant.

• Seal has an Integrated splash guard.

FBU was established in 2007, with FBU trademark and is constantly developing series of cartridge seals conforming to standards of ISO , ANSI, DIN, and API ,which are widely used in industry such as chemical processing, paper & pulp, Iron Mine, marine and food processing.

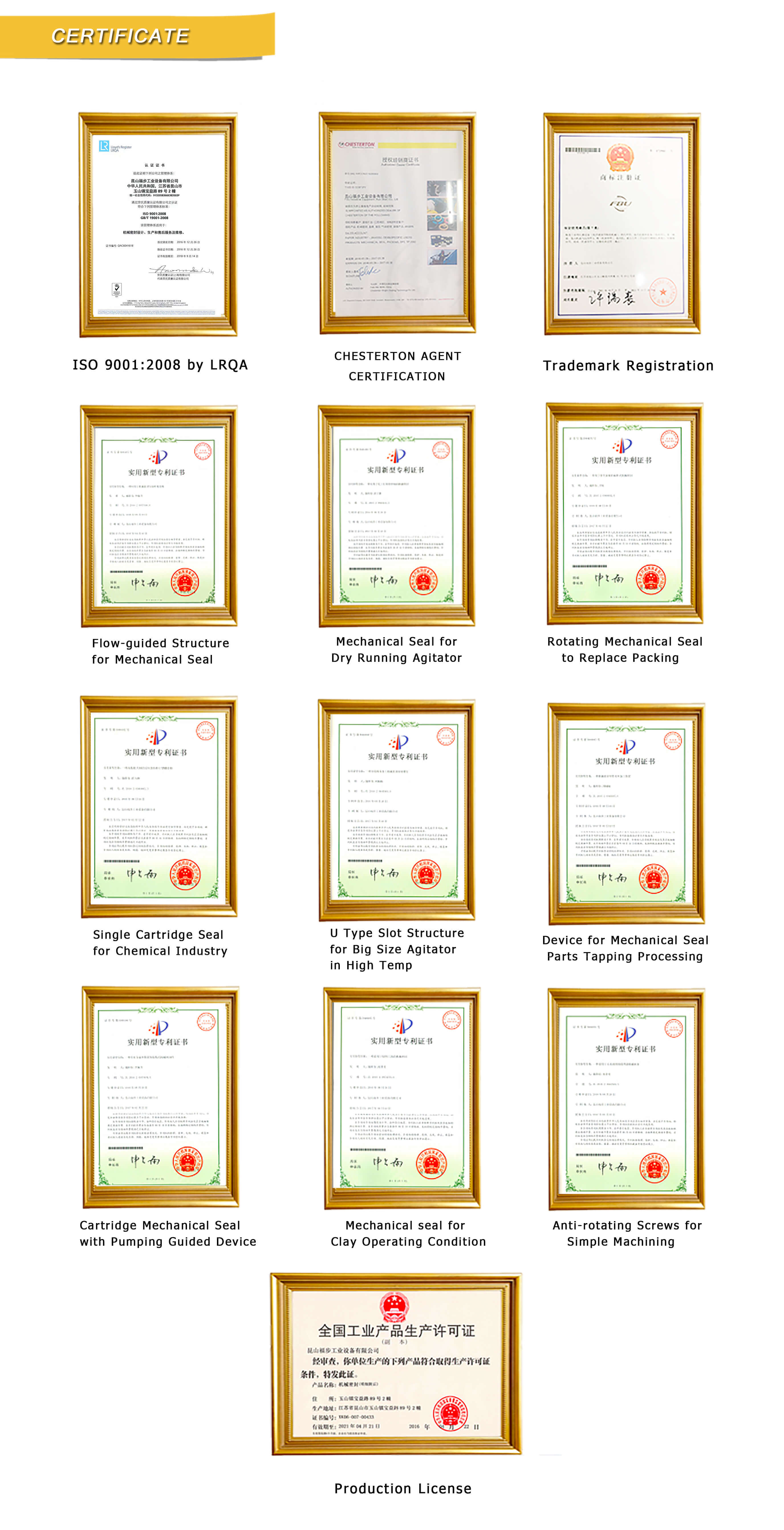

Our core business is cartridge mechanical seals and seal supporting system, FBU can design, manufacture, and recondition mechanical seals as per ISO 9001:2008 LRQA assessed management.

Choose FBU, find us to save your Time and Money.

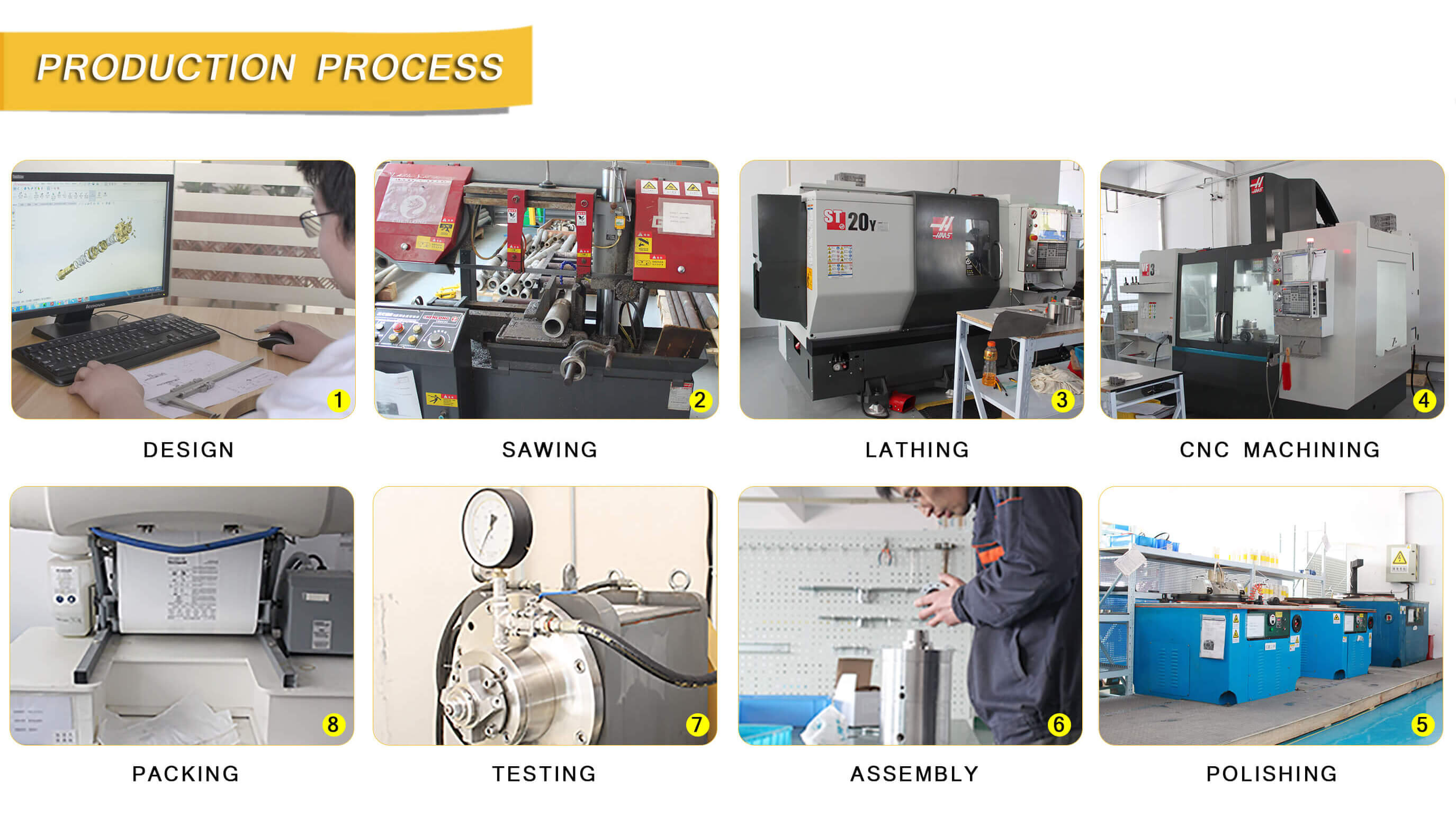

How we do our jobs ???

Want to know more about us, kindly feel at free to sale@fbuseals.com

| Materials of Construction | |

|---|---|

| Rotating Face: |

Sintered Silicon Carbide |

| Stationary Face: | Sintered Silicon Carbide |

| Elastomers: |

Viton® Standard |

| Aflas® or Kalrez ® | |

| Metal Parts: | 316 S.S. |

| Springs: |

316 S.S. |

| Operating Conditions | |

| Size: |

30,40,50,60,80,90mm |

| Temperature: | 150°C |

| Speed: | 3600 RPM |

| 2900 RPM | |

| 1800 RPM | |

| Pressure: | 25 BAR |

| Runout: | Up to .060 (1.5 mm) TIR |

| Radial movement | |

Want to know more about FBU, welcome to contact us at sale@fbuseals.com