JM can process 0.5-200mm sheet material and provide a variety of surface treatment: galvanized, polishing, electrophoresis, spray, nickel, paint, Dacromet and so on.

JM can design and manufacturing special products according to the drawings or samples for your requirements

|

|

|

|

|

|

JMCWP-001 |

JMCWP-002 |

JMCWP-003 |

JMCWP-004 |

|

|

|

|

|

|

|

|

|

|

JMCWP-005 |

JMCWP-006 |

JMCWP-007 |

JMCWP-007 |

|

|

|

|

Flange |

|

Product Feature: |

High Surface Finish; Uniform coating thickness; High tensile strength(>600); Excellent atmospheric corrosion resistance,welding and cold forming performance; Leaf-shaped crystalline pattern; Beautiful Designed |

|

Materials: |

stainless steel, iron ( SPCC, SECC, SPTE, tinplate), aluminum alloy, red copper, brass, bronze alloy are available. |

|

Processing Craft: |

Laser Cutting, CNC Punching, CNC Bending, Tig Welding, Mig Welding, Riveting, Grinding, Stamping; |

|

Surface Finished: |

Powder Coated, Hot Galvanized, Painting, Polishing, Brushing, Cataphoresis, Chrome/Zinc/Nickel Plating/Anodize/Electronic Polish, Silk-screen etc; |

|

Major Equipment: |

TRUMPF LASER CUTTING MACHINE; |

|

CNC SHEAR MACHINE; |

|

|

CNC PUNCHING MACHINE; |

|

|

CNC BENDING MACHINE; |

|

|

TIG WELDING MACHINE; |

|

|

MIG WELDING MACHINE; |

|

|

SPOT WELDING MACHINE; |

|

|

STAMPING MACHINE; |

|

|

ROLLING MACHINE; |

|

|

PIPE BENDER; |

|

|

Serve Type: |

OEM,ODM; |

|

Files Formats: |

Pro/Engineer, Solidworks, Auto CAD |

|

Certification: |

ISO9001:2008,TUV; |

|

Application: |

Appliance/ Automotive/ Agricultural Electronics/ Military/ Marine/ Mining/ Hydraulics/ Valves/ Oil and Gas/ Electrical/ Construction/ machinery/ furniture/ LED/ woodboard/ wall etc |

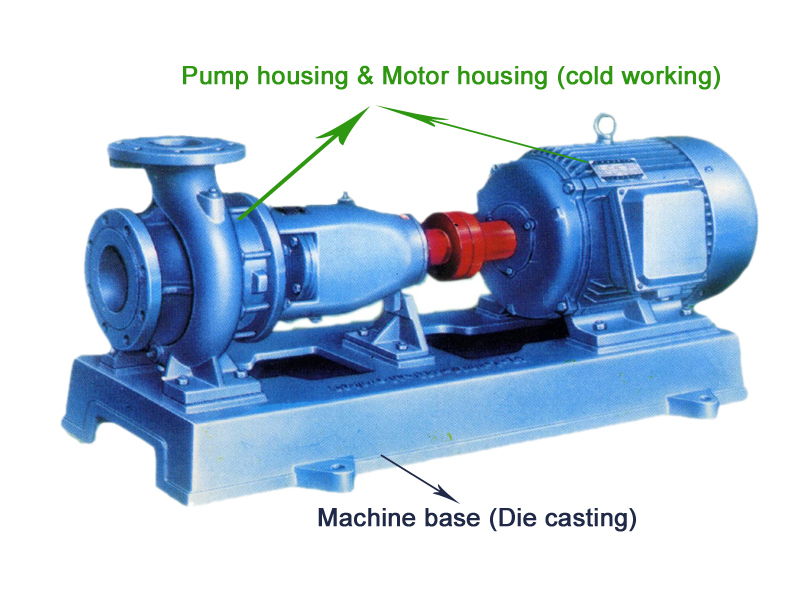

Description of cold working: Cold

working usually refers to shearing, bending, stamping and other processing methods

of metals without heating first. It can be used for sheet metal production of

all kinds of machinery and machines, and also can be used for manufacturing

various hardware products. Cold working is a traditional processing method.

While various welding methods, such as AC/DC arc welding, argon arc welding,

oxygen welding, CO2 protection welding, brazing, etc. are used to assist the

cold working. The cold working includes cold bending of various sectional

materials and rounding of sheet metals.

Description of cold working: Cold

working usually refers to shearing, bending, stamping and other processing methods

of metals without heating first. It can be used for sheet metal production of

all kinds of machinery and machines, and also can be used for manufacturing

various hardware products. Cold working is a traditional processing method.

While various welding methods, such as AC/DC arc welding, argon arc welding,

oxygen welding, CO2 protection welding, brazing, etc. are used to assist the

cold working. The cold working includes cold bending of various sectional

materials and rounding of sheet metals.

Advantages: It mainly features by stable product performance after processing, to maintain the original metal property of the material.