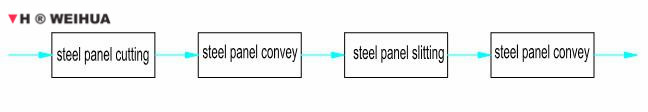

Transverse machine framing pre-cutter is used to cut off the steel panel when finish the single batch of order, so that can avoid the waste. Slitting unit can meet the requirement to produce different products with the standard steel coil. Transverse machine framing cutter: make use of the up and down action of hydraulic cylinder to cut off steel panel, adopts linear guide rail for machine framing cutting.

The function: it is used when produce the sandwich panel with a fixed length or test the roll forming machine; cut off the steel panel before the single batch products finish to avoid waste; cut off the steel panel when emergent stop machine and normal stop machine. Side slitter: make use of gear by the blade on the up and down revolving shaft for slitting, it is used to slit the wide material from the side. It includes the driving device of blades and rewinder of side scrap, which can meet the requirements of different customers. This slitter adopts special design, it can move the hole assembly quickly by linear guide rail at side and adjusting threaded rod, so that can change different slitting width. The gap between blades does not need to be adjusted; the efficiency can be more than 5 times than the normal disc cutter.

1)Supporting roller: φ70mm;

2)Material of blade: Gr12mov;

3)Hardness of blade: HRC60°-62°;

4)Motor power: 5.5kw;

5)Plane cutter base linear guide rail: 2 sets;

6)Slitting width: min. 5mm, max. 150mm;

7)Slitting thickness: 0.4-0.8;

8)Slitter base guide rail: 4 sets

- Continuous Sandwich Panel Production Line

- Discontinuous Sandwich Panel Production Iine

-

Roll Forming Machine

- Roof & Wall & Door Sheet Roll Forming Machine

- Deck Floor Roll Forming Machine

- C & Z Purlin Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Downpipe Roll Forming Machine

- Box Beam Roll Forming Machine

- Folding, Shearing & Bending Machines

- Steel Springboard Roll Forming Machine

- Steel Sheet Pile Roll Forming Machine

- No-girder And Columniation Curve Roll Forming Machine

- Slitting & Cut to length line

- PU Raw Material