Size range: NPS 1"~12"

Working pressure: NPS 1 "~2"

Working temperature:-29℃ ~ +85℃

Pressure ratings:≤ 150 PSI

Suitable Medium:tough slurries, abrasives, and corrosive chemical applications.

Body Material:Cast Iron / Aluminum 14" and larger body sizes are of fabricated steel design.

Sleeves Material: NR / NBR / EPDM

- The DREAMAX Pinch Valve is a completely enclosed, manually operated valve.

- Its reliable, maintenance-free design is perfectly suited for tough slurries, abrasives, and corrosive chemical applications.

- The enclosed body offers protection against moving parts and offers additional safety in the event of sleeve failure. The heart of the Pinch Valve is a long-lasting, flexible rubber sleeve, available in a wide variety of elastomers suitable for any application.

- In addition, the sleeve, which is the only part of the valve exposed to the line process, eliminates maintenance and the need for expensive, anticorrosion body materials.

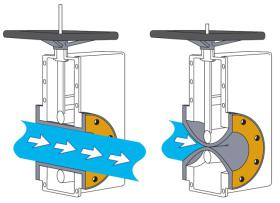

- During operation, two pinch bars squeeze the flexible rubber sleeve, allowing the Pinch Valve to achieve a variable and stable flow rate. Fully open, the valve allows for full, straight through flow, eliminating areas where solids could build up and impair operation. Fully closed, the Pinch Valve maintains complete closure, with no leakage in either direction. Valve operation will not freeze and operating torques remain constant, even if the valve has remained in the open or closed position for years.

1.Completely enclosed body

The enclosed body valve is the most common body type. Its enclosed design prevents premature sleeve deterioration and protects the sleeve from the environment, making it extremely safe to operate. Enclosed body pinch valves can be manufactured of cast iron, fabricated carbon steel, aluminum. Valve diameters begin from NPS 1".

2.Optimum tightness

Even large solid particles are shut off by the sleeve, which is particularly resistant to abrasion and corrosion, hence shut off without leaks.

3.Full port, streamlined centerline closure

Standard full port designs, streamlined centerline closure and

Class VI shutoff provide outstanding elastomer wear life as

well as precise, repeatable linear flow control.

4.Self-cleaning, no plugging

Self-cleaning sleeve provide 100 % tight shut-off even if solids have built up on the sleeve wall. When compressed, any crystallized particles flake off the sleeve surface and are washed downstream.

5.The sleeves inner lining reinforcing cords

The sleeve is a reinforced construction making it the pressure containing part of the valve. The quality of the sleeve is crucial to the life time and anti-abrasion characteristics of the Pinch valve,DREAMAX Pinch Valve sleeves guarantee high wear and corrosion resistance, a trouble free operation, and extended lifetime.

6. Low pressure drop

7. Easy maintenance

The sleeves and other parts can be replaced easily.

8. Bi-directional

2.Face to Face dimension standard as to: MFR-STD

3.Flange dimension conforms as to: ASME B16.5

4.Testing And Inspection as to: API 598

5.Pressure-temperature conforms as to: ASME B16.34

-

Valves

-

Air Release Valves

- Three Functions Air Valve/ Combination Air Release Valve (FOX)

- Wastewater Air Valve/ Combination Sewage Air Valve (Gamm HP)

- High Anticorrosive Air Valve/ Combination Inner Lined Air Valve

- Two Functions Air Valve/ Air Release Valve(Omega)

- Two Functions Air Valve/ Inner Lined Sewage Air Valve(Omega HP)

- Combination Lined Sewage Air Valve (Delta HP)

- Micro-Air Release Valve/Automatic air release valve (A200)

- Pressure Reducing Valves

- Ball Valves

- Butterfly Valves

- Strainers

- Check Valves

- Pinch Valves

- Diaphragm Valves

-

Air Release Valves

- Fittings

- Pipes and Tubes