ESD System

Overview

The safety instrument layout protection of formaldehyde enterprise relates to the workshop, furnace and tank yard.

The objects of the parameters monitoring are pressure, liquid level, flow, temperature and combustible gas.

ESD interlocking objects are the main fan , off gas blower,the feeding pump of methanol, methanol gas shut-off valve, methanol liquid shut-off valve and methanol storage tank inlet and outlet pump, formaldehyde products tank inlet valve and formaldehyde storage tank outlet pump, and steam drum remote electronic control pressure relief valve; workshop fan, etc.

Jiangsu Kaimao Chemical Technology Co., Ltd. has published nearly 7 papers in China's Formaldehyde Industry , focused on safety instruments SIS system and emergency stop automatic protection ESD system, and has carried 14 sets of safety instrument SIS+ESD monitoring system engineering project.We have rich experience in the section of safety instruments, ESD system designing and project engineering.

SIS Safety instrument accuracy: ±0.2%、±0.5% ;

Anti-hazard classification ⅡCT4∽6

ESD System accuracy: ±1% ;

Safety barrier output precision: 0.1%FS;

Safety barrier Temperature drift: 0.05%FS/10℃

Safety level: SIL1∽4

According to the consequences and risks of the safety instrument function failure, the safety instrumental function can be divided into different safety integrity levels. (SIL1-4,The highest level is L4) . Different levels of safety instrument circuit have different technical requirements in the design, manufacture, installation and commissioning, and operation and maintenance.

The higher the grade, the higher the price of ESD. Generally SIL-3 grade is more than 3 times of the basic system of DCS.

1.ESD(Emergency Shut Down)

For the oxidation process, which is the tenth of 15 kinds dangerous chemical process prescribed by China national Safety administration,the basic requirements for safety control are: (oxidation) reaction temperature, (system) pressure alarm and interlocking(stopping air blower); proportion of reactive materials (oxygen alcohol mole ratio)control and interlocking and emergency cut-off system(methanol feeding shut-off valve, roots blower, off gas blower), gas phase oxygen content monitoring, safety venting system, monitoring of temperature and pressure liquid level of the tank and pump interlock; combustible(methanol, hydrogen) and toxic (formaldehyde) gas detection and alarm interlocking.The safety instrument layout protection of formaldehyde enterprise relates to the workshop, furnace and tank yard.

The objects of the parameters monitoring are pressure, liquid level, flow, temperature and combustible gas.

ESD interlocking objects are the main fan , off gas blower,the feeding pump of methanol, methanol gas shut-off valve, methanol liquid shut-off valve and methanol storage tank inlet and outlet pump, formaldehyde products tank inlet valve and formaldehyde storage tank outlet pump, and steam drum remote electronic control pressure relief valve; workshop fan, etc.

Jiangsu Kaimao Chemical Technology Co., Ltd. has published nearly 7 papers in China's Formaldehyde Industry , focused on safety instruments SIS system and emergency stop automatic protection ESD system, and has carried 14 sets of safety instrument SIS+ESD monitoring system engineering project.We have rich experience in the section of safety instruments, ESD system designing and project engineering.

2.Performance

SIS Safety instrument accuracy: ±0.2%、±0.5% ;

Anti-hazard classification ⅡCT4∽6

ESD System accuracy: ±1% ;

Safety barrier output precision: 0.1%FS;

Safety barrier Temperature drift: 0.05%FS/10℃

Safety level: SIL1∽4

According to the consequences and risks of the safety instrument function failure, the safety instrumental function can be divided into different safety integrity levels. (SIL1-4,The highest level is L4) . Different levels of safety instrument circuit have different technical requirements in the design, manufacture, installation and commissioning, and operation and maintenance.

The higher the grade, the higher the price of ESD. Generally SIL-3 grade is more than 3 times of the basic system of DCS.

3.Operation interface

-

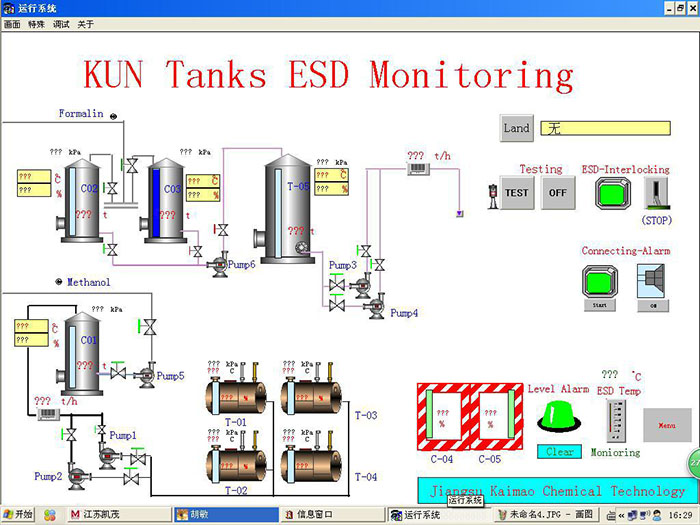

Safety interlocking monitoring interface for storage tank area

Safety interlocking monitoring interface for storage tank area

-

Temperature / pressure / liquid level alarm (interlocking) value setting interface for storage tank

Temperature / pressure / liquid level alarm (interlocking) value setting interface for storage tank

-

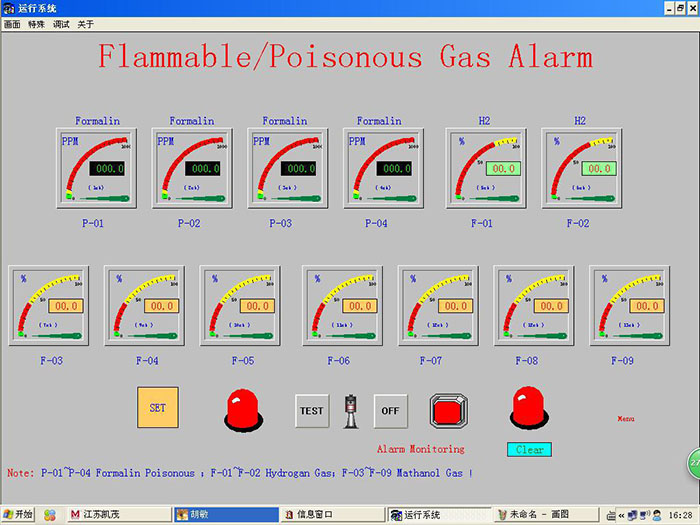

Combustible and poisonous gas alarm (interlocking) monitoring interface

Combustible and poisonous gas alarm (interlocking) monitoring interface

4.Performance table

| ①哈尔滨巨业化工有限公司 | 3万吨甲醛界区ESD系统 | 2010年 |

|---|---|---|

| ②哈尔滨同进科技有限公司 | 5万吨甲醛界区ESD系统 | 2013年 |

| ③牡丹江兰华化工有限公司 | 2万吨甲醛界区ESD系统 | 2011年 |

| ④延吉汪清天合化工有限公司 | 1万吨甲醛界区ESD系统 | 2011年 |

| ⑤荷泽泰和木业有限公司 | 5+3万吨甲醛界区2套ESD系统 | 2012年 |

| ⑥通化化工股份有限公司 | 12万吨合成氨界区4套ESD系统 | 2012年 |

| ⑦长春和禾生物化工有限公司 | 6000吨多元醇加氢裂解界区ESD系统 | 2013年 |

| ⑧印度AC公司 | 3.6万吨甲醛界区ESD系统 | 2014年 |

| ⑨印度WS公司 | 3.6万吨甲醛界区ESD系统 | 2014年 |

| ⑩印度AK公司 | 2万吨甲醛界区ESD系统 | 2015年 |

Products

TOP