Falling Film Evaporator

Introduction

First, the material will be pumped into the top of the tube, then fall along the tube’s inwall and forming a liquid film, In this process, the liquid film begins boiling as the tube’s heating, The residual liquid and steam will be separated in the bottom of the tube.

The flow of material in the exchange tube will be determined reasonably to avoid drying tube in the bottom, at the same time, it can ensure the thickness of the film and reach the best heat exchange efficiency and the lowest power consumption.

The falling film evaporator can be used cycle evaporation and single way evaporation

The highest capacity can reach 200T/h per unit.

Suitable for heat sensitivity material.

Suitable for low concentration,low solid content,low scaling material.

High heat transfer coefficient,low temperature difference,vacuum evaporation.

Ensure the material keep boiling in the heat exchange tube,avoid drying wall and scaling caused by intense evaporation.

Low circulation volume,low power consumption.

Parameter

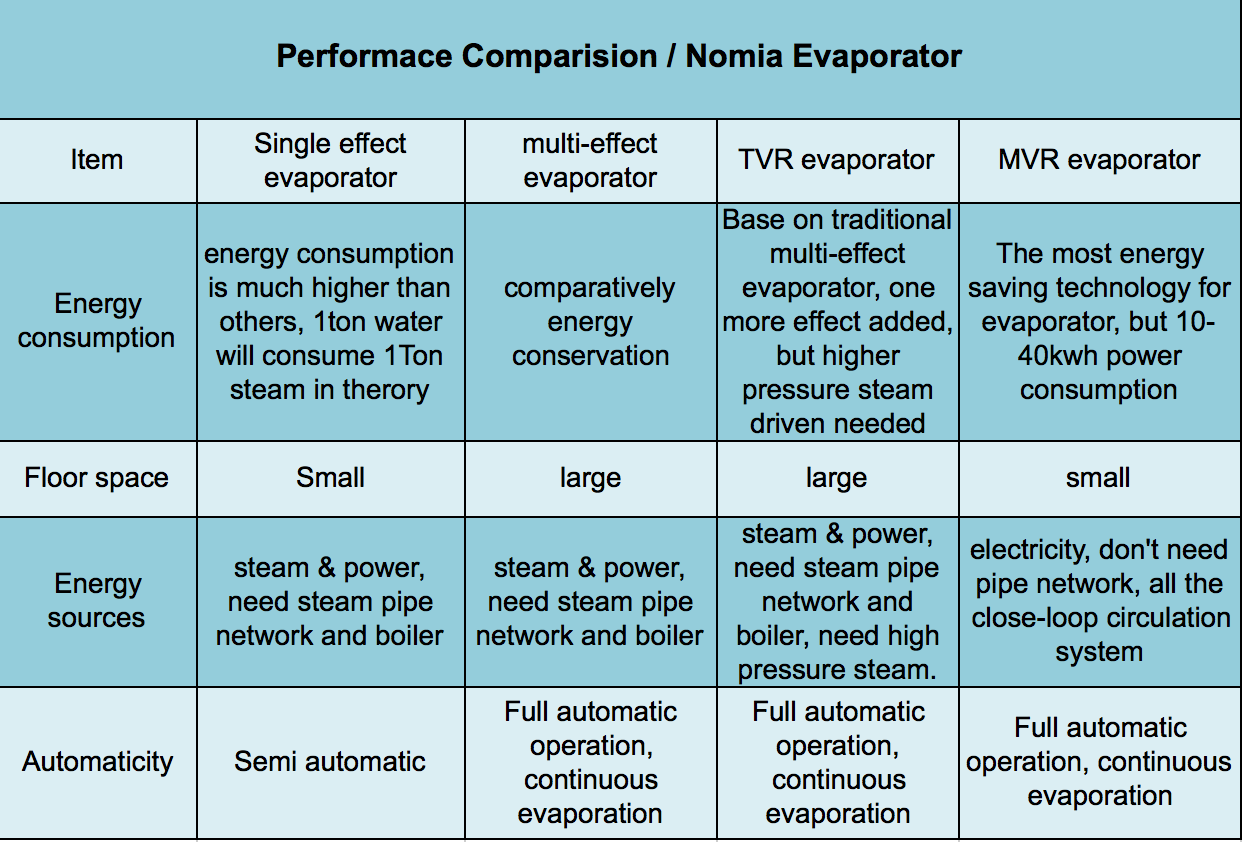

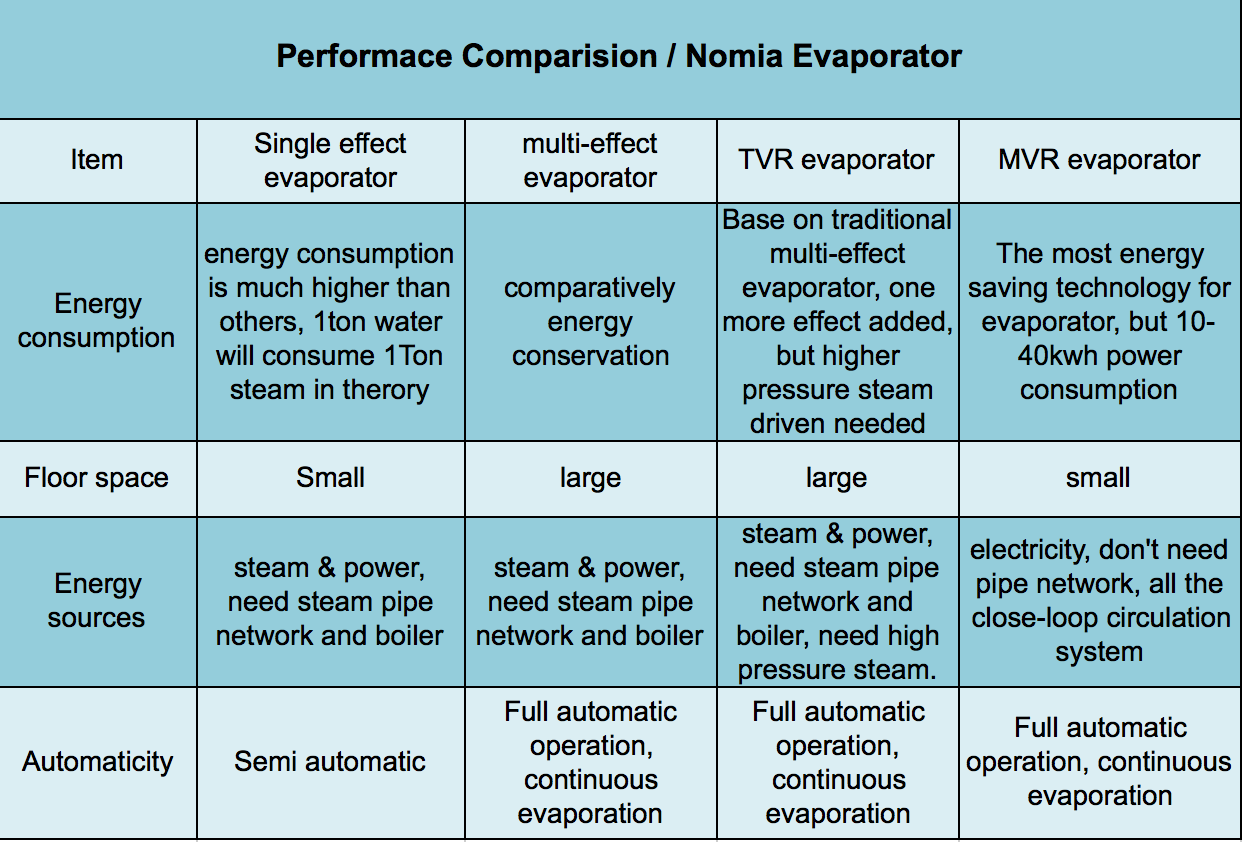

Evaporator performance

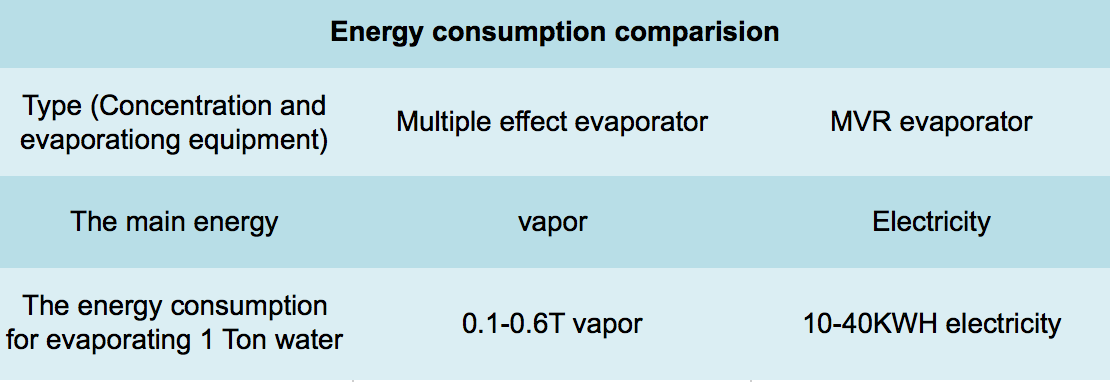

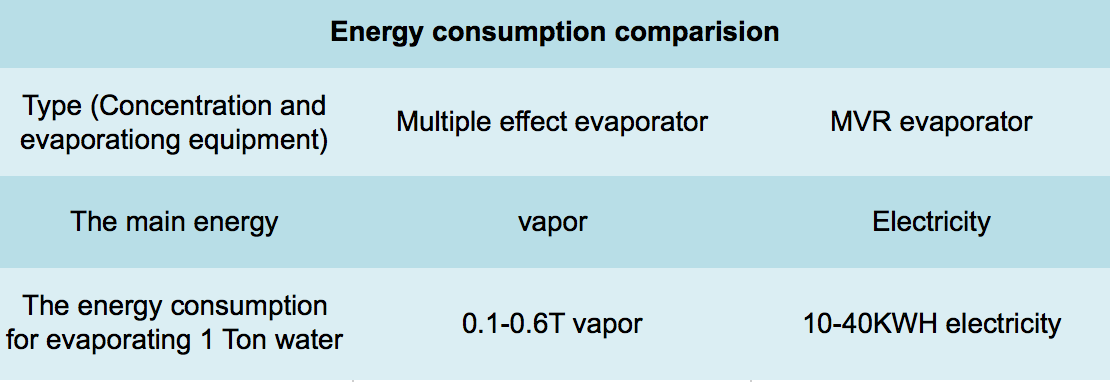

Evaporator energy consumption

Evaporator energy consumption

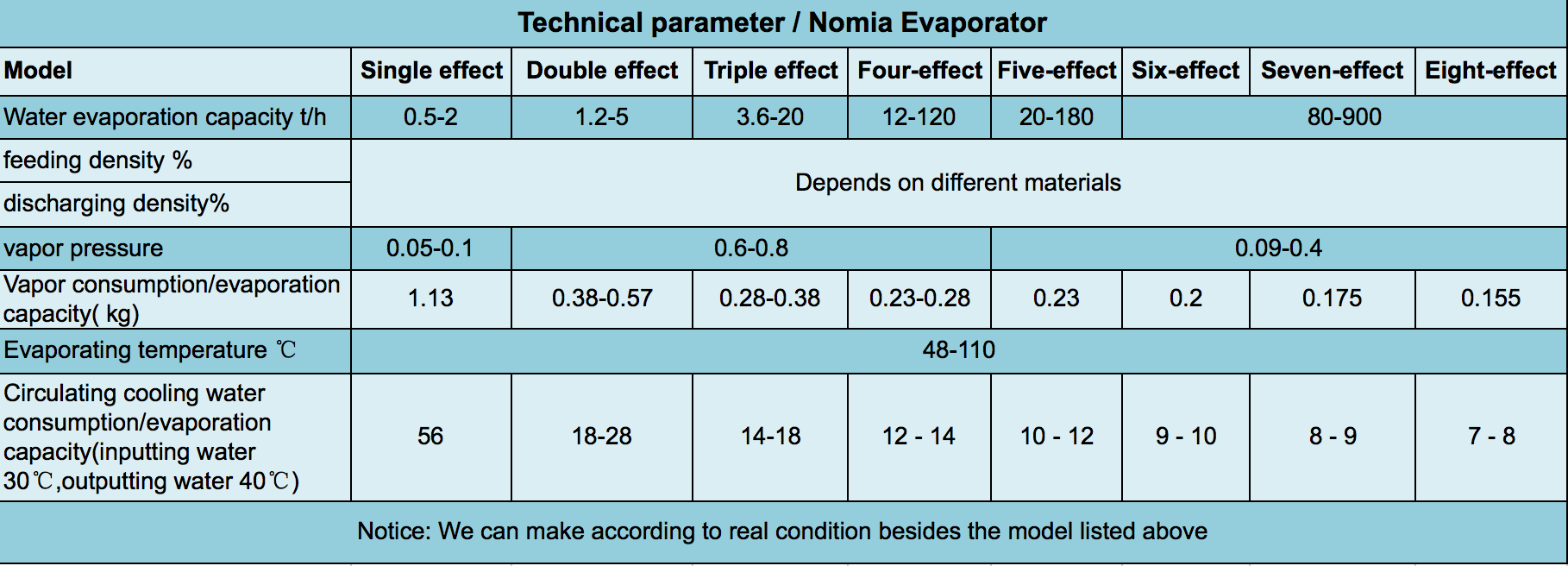

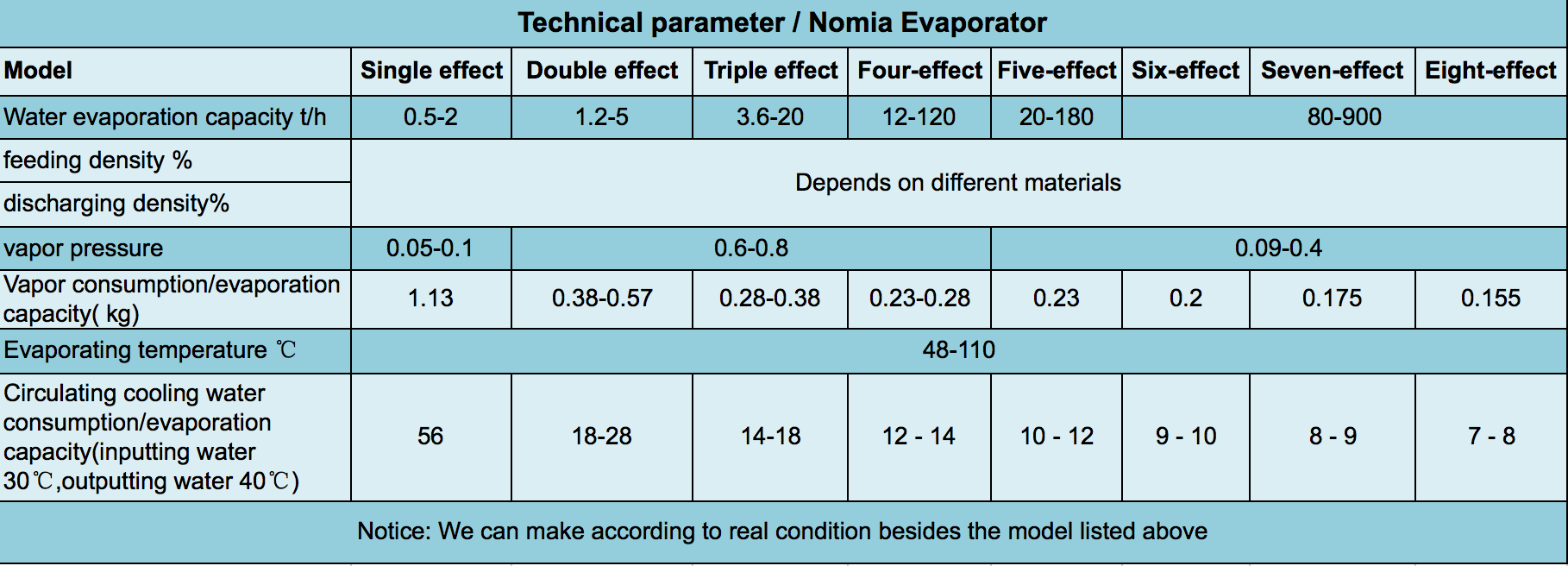

Basic technical data

Basic technical data

First, the material will be pumped into the top of the tube, then fall along the tube’s inwall and forming a liquid film, In this process, the liquid film begins boiling as the tube’s heating, The residual liquid and steam will be separated in the bottom of the tube.

The flow of material in the exchange tube will be determined reasonably to avoid drying tube in the bottom, at the same time, it can ensure the thickness of the film and reach the best heat exchange efficiency and the lowest power consumption.

The falling film evaporator can be used cycle evaporation and single way evaporation

The highest capacity can reach 200T/h per unit.

Suitable for heat sensitivity material.

Suitable for low concentration,low solid content,low scaling material.

High heat transfer coefficient,low temperature difference,vacuum evaporation.

Ensure the material keep boiling in the heat exchange tube,avoid drying wall and scaling caused by intense evaporation.

Low circulation volume,low power consumption.

| Evaporation | 200kg/h | 500kg/h | 1000kg/h | 2000kg/h | 3000kg/h | 4000kg/h | 5000kg/h | 10000kg/h |

|---|---|---|---|---|---|---|---|---|

| L*W*Hmm | 2000*1200*2200 | 2500*1500*2500 | 3000*1800*5200 | 3300*2400*7800 | 3500*2600*7800 | 4500*2800*10000 | 4500*3000*10000 | 6500*3800*10000 |

| area | Heater | weight/kg | Separator | weight/kg | Preheater | weight/kg | Crystallization tank | weight/kg |

| 5m² | Φ273*2400 | 170 | Φ400*700 | 40 | Φ | Φ500*1800 | 120 | |

| 10 | Φ450*1725 | 330 | Φ600*1800 | 120 | Φ | Φ700*2000 | 180 | |

| 15 | Φ550*1775 | 460 | Φ700*1800 | 170 | Φ | Φ800*2200 | 230 | |

| 20 | Φ550*2275 | 560 | Φ800*1900 | 220 | Φ | Φ900*2300 | 290 | |

| 30 | Φ650*2326 | 800 | Φ900*2000 | 280 | Φ | Φ900*2600 | 340 | |

| 40 | Φ750*2276 | 1040 | Φ900*2450 | 320 | Φ | Φ1000*3000 | 400 | |

| 50 | Φ700*3750 | 1240 | Φ1000*2450 | 390 | Φ | Φ1100*3000 | 450 | |

| 60 | Φ750*3776 | 1430 | Φ1100*2450 | 480 | Φ | Φ1200*3200 | 510 | |

| 70 | Φ800*4200 | 1450 | Φ1100*2750 | 540 | Φ | Φ1300*3200 | 580 | |

| 80 | Φ750*5176 | 1750 | Φ1200*3000 | 600 | Φ | Φ1300*3300 | 650 | |

| 90 | Φ550*7075 | 2000 | Φ1200*3300 | 650 | Φ | Φ1400*3500 | 730 | |

| 100 | Φ700*7200 | 2300 | Φ1200*3600 | 720 | Φ | Φ1500*3700 | 800 | |

| 110 | Φ750*7176 | 2540 | Φ1300*3650 | 800 | Φ | Φ1500*3800 | 850 | |

| 120 | Φ780*7176 | 2750 | Φ1300*3850 | 870 | Φ | Φ1600*3800 | 910 | |

| 130 | Φ800*7200 | 2990 | Φ1400*3900 | 940 | Φ | Φ1600*3900 | 960 | |

| 140 | Φ820*7226 | 3220 | Φ1400*4100 | 1000 | Φ | Φ1700*3900 | 1010 | |

| 150 | Φ850*7226 | 3450 | Φ1500*4150 | 1075 | Φ | Φ1700*4000 | 1060 | |

| 160 | Φ880*7226 | 3680 | Φ1500*4350 | 1150 | Φ | Φ1700*4100 | 1100 | |

| 170 | Φ880*7226 | 3850 | Φ1600*4200 | 1230 | Φ | Φ1800*4100 | 1150 | |

| 180 | Φ900*7250 | 4140 | Φ1600*4400 | 1280 | Φ | Φ1800*4200 | 1200 | |

| 190 | Φ920*7250 | 4350 | Φ1700*4600 | 1360 | Φ | Φ1800*4300 | 1240 | |

| 200 | Φ950*7300 | 4540 | Φ1800*4900 | 1440 | Φ | Φ1800*4500 | 1280 |

TOP