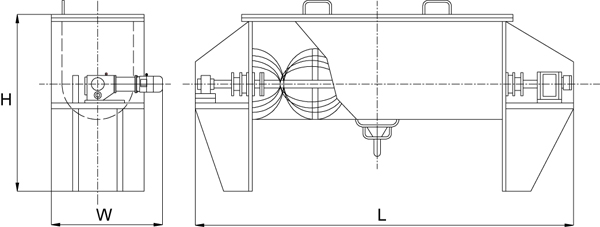

Horizontal ribbon belt mixing machine comprises of U-shape container, transmission parts and spiral belt agitating blades which usually have double or triple layers with outside screw gathering the material from sides to center and inside screw transmitting the material from center to sides to form convection mix. Ribbon mixing machine has a good result in the mix of viscosity or cohesion powder and of putting liquid and mash material into the powder. The cylinder cover can be fully open so as to clean and change the device.

|

Type |

FDL |

|||||||||||

|

Spec(m3) |

|

0.5 |

1 |

2 |

3 |

4 |

5 |

6 |

8 |

10 |

12 |

15 |

|

Working capacity |

0.4~0.6 |

|||||||||||

|

Power(Kw) |

|

5.5 |

11 |

15 |

18.5 |

22 |

30 |

37 |

45 |

55 |

55 |

75 |

|

Speed(rpm) |

|

66 |

41 |

41 |

33 |

33 |

26 |

26 |

26 |

20 |

20 |

17 |

|

Dimension(mm) |

L |

1672 |

1970 |

2480 |

2880 |

3026 |

3518 |

3905 |

4398 |

4500 |

4486 |

5363 |

|

W |

1142 |

1437 |

1561 |

1895 |

1947 |

1945 |

1683 |

1960 |

2070 |

2250 |

2250 |

|

|

H |

1300 |

1500 |

1830 |

2083 |

2235 |

2233 |

2286 |

3150 |

2667 |

2737 |

3070 |

|

|

Weight(Kg) |

955 |

1400 |

2500 |

3300 |

3600 |

4620 |

5300 |

6800 |

8902 |

9520 |

9950 |

|