Glass Fiber Filter Cartridges

0

All fluoropolymer filter cartridges are constructed of hydrophilic PTFE membrane and PVDF components, offering high throughputs, high flow rates and long service life. Due to their characteristics of superior chemical compatibility and oxidation resistance, they are ideal for oxidized water filtration application in bottled water industry.

Features and Benefits

● PTFE membrane with PVDF structure

● Low adsorption ability

● Broad chemical compatibility

● Good resistance to high temperature and oxidation

Quality

● Cartridges produced in a controlled environment

● Manufactured according to ISO9001 certified Quality Management System

Specification

All Fluoropolymer Filter Cartridge for Oxidized Water in Bottled Water

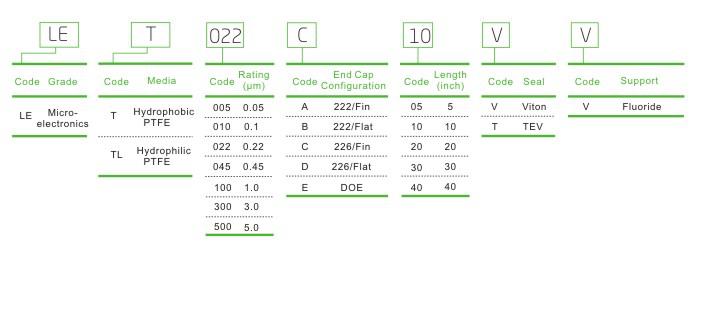

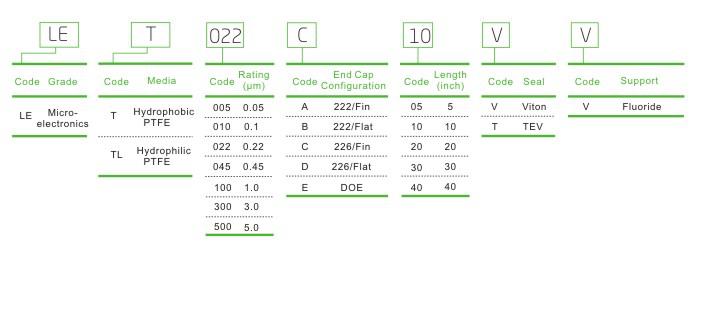

Ordering Information

All Fluoropolymer Filter Cartridge for Oxidized Water in Bottled Water

Share

All fluoropolymer filter cartridges are constructed of hydrophilic PTFE membrane and PVDF components, offering high throughputs, high flow rates and long service life. Due to their characteristics of superior chemical compatibility and oxidation resistance, they are ideal for oxidized water filtration application in bottled water industry.

Features and Benefits

● PTFE membrane with PVDF structure

● Low adsorption ability

● Broad chemical compatibility

● Good resistance to high temperature and oxidation

Quality

● Cartridges produced in a controlled environment

● Manufactured according to ISO9001 certified Quality Management System

Specification

All Fluoropolymer Filter Cartridge for Oxidized Water in Bottled Water

| Materials of Construction | |

| Filter Media | Hydrophilic PTFE |

| Core, Cage | PVDF |

| End Caps | PVDF |

| O-rings/Gasket | Viton/TEV |

| Sealing technology | Thermal Bonding, No Adhesives |

| Dimensions | |

| Diameter | Φ 68 (2.67 in) |

| Length(in) | 5, 10, 20, 30, 40 |

| Filtration Area | |

| ≥ 6.4 ft2/10 in (≥ 0.60 m2/250 mm) | |

| Pore Size, μm | |

| 0.1, 0.22, 0.45, 1.0 | |

| Maximum Operating Temperature | |

| <95 ℃(203℉) | |

| Maximum Forward Differential Pressure | |

|

4.2 bar@23℃(60.9 psi @73.4℉) 0.6 bar@95℃(8.7 psi @203℉) |

|

Ordering Information

All Fluoropolymer Filter Cartridge for Oxidized Water in Bottled Water

TOP