| Model | DPM-ALS204 |

|---|---|

| Driving Mode | German Avery brand |

| Yield(pcs/min) | 150-200 |

| Operating direction | Leftor Right |

| Conveyor Speed(m/min) | ≤40 |

| Labeling Accuracy | ±1.0mm |

| The inner diameter of label roll | 76mm |

| The outer diameter of label roll | 350mm(max) |

| The suitable size of label | Width : 15-160mm L:15-200mm |

| The suitable size of labeling objects | Can customized depends on client product |

| Printeruseair | 5kg/cm² |

| Voltage (InChina) | AC220V50/60HZ Single phase |

| Machine size | 2600(L)800(W)1300(H)mm |

| No | Name | Model | Unit | Brand |

|---|---|---|---|---|

| 1 | PLC control system | 6ES7212-1A | 1Set | SIEMENS |

| 2 | Touch-screen | 6AV6648-01A | 1Set | SIEMENS |

| 3 |

Photoelectric sensor (Check tag ) |

FS-N18N | 1Set | Japan KEYENCE |

| 4 |

Photoelectric sensor (Check opaque label) |

GS61 | 1Set | German Leuze |

| 5 | Servo motor | 2004-RZ08BAIAN | 1Set | America AB |

| 6 | Drive | 2003-CSD3-08BX2 | 1Set | America AB |

| 7 | Main transport motor | 90W1:30 | 1Set | German JSCC |

| 8 | Speed Controller | 25-90W | 1Set | German JSCC |

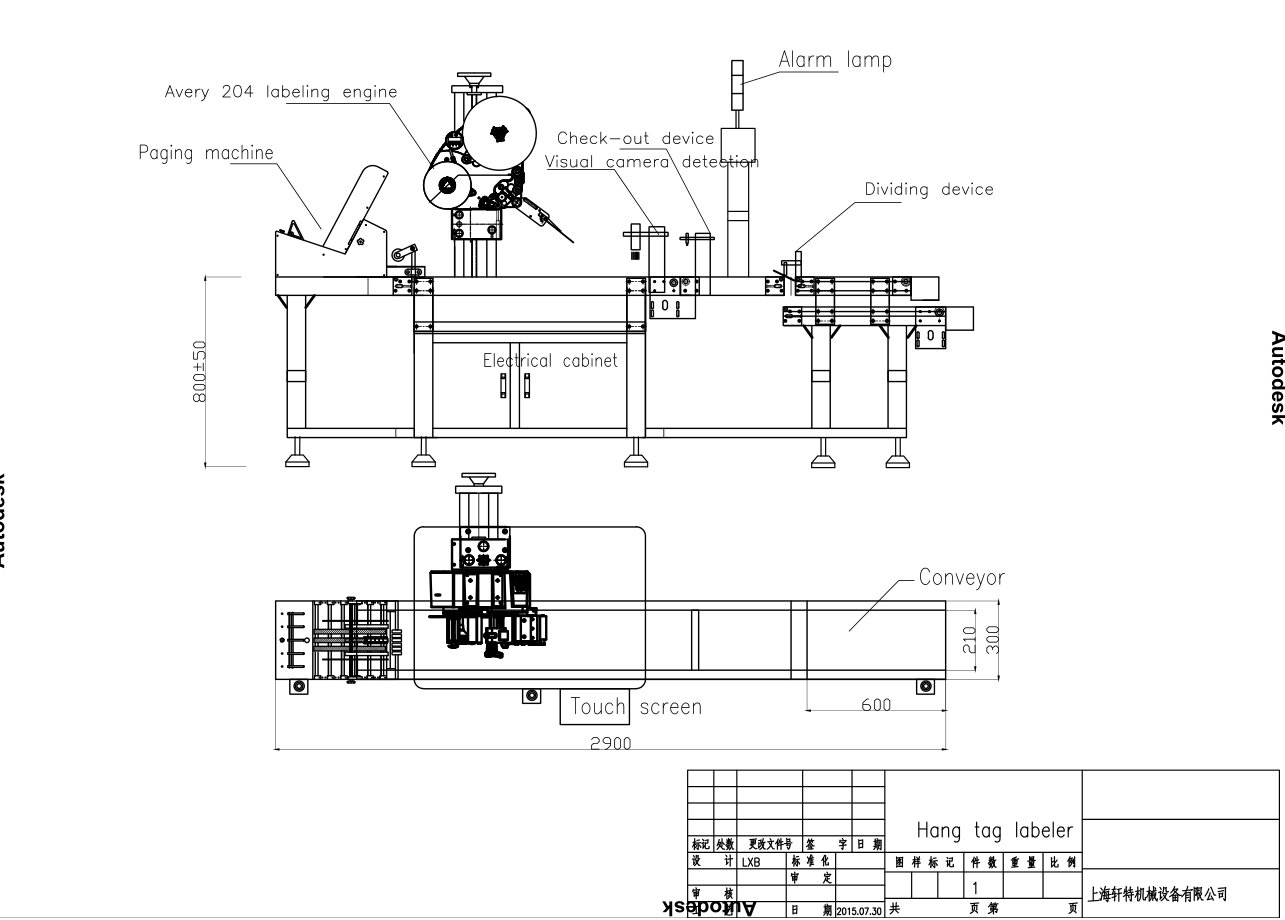

1. Loading&Paging:

Put the tags into the received hopper by hands, the same part of the paging belt brings the tag out to the main transmission platform of the feeding device bottom at the same time.

2. Detecting&Check-out:

After labeling, tags go into the detecting device. Sensor triggering visual camera detect tags labeling quality if ok or not , unquailty tags been check-out into waste hopper , good quality tags go on delivery .

3. Dividing & Collecting Device:

All the good quality tags count by sensor, when 1# hopper received a certain number, tags will be delivered to 2# hopper .

-

Catalogues

- Sticker Labeling Machine

- Front & Back Labeling machine

- Round Bottle Labeling machine

- Labeling Applicator

- Rotary Labeling machine

- Horizontal Way Labeling machine

- Top Labeling machine

- Paging Labeling System

- Multi sides labeling machine

- Bottom Labeling machine

- Top & Bottom Labeling machine

- Top & Side Labeling machine

- Online Printing Labeling system

- Carton Corner Labeling machine

- Fix Position Labeling machine

- Bucket Labeling machine

- Three Labels Labeler

- Dental Floss Packaging Line

- Four sticker labeling machine

- Customization