Hidden Roof Sheet Roll Forming Machine

3

Share

TECHNICAL PARAMETER

3.Decoiler capacity: 5T

4.Machine stand: welded by steel structure, shot blast after welding, get rid of inside stress

5.Motor power of forming machine:7.5KW

6.Motor power of hydraulic station:3KW

7.Roll stand:24 stations

8.Forming speed:12m/min

9.Material of roller:high-grade 40Cr alloy steel

10.The surface of roller coating chrome:single surface 0.05mm

11.Type of forming machine: wallboard type chain transmission

12.Bearing guard: ¢50

13.Diameter of shaft: ¢75mm

14.Chain: 16A

15.type of cutting:hydraulic cutting

16.Material of cutting blade: Cr12, Quenching hardness HRC58°-62°

17.Thickness of steel coil: 0.4-0.8mm

18.Panel width of feeding: 1000mm

19.Tolerance of length:10m±2mm

20.Specific size of profile: conform to roll forming panel GB/T12755-2008 standard used for china construction

21.Form of guiding with feeding station:side trolley type

22.Transducer: Holip (Danfoss)

23.Computer adopts PLC,OMRON Series

24.Hydraulic systemic working pressure: 12Mpa

25.Computer control system: whole machine adopts industrial computer PLC control, operating board adopts Xinjie OP320A

26.Output table: roller type

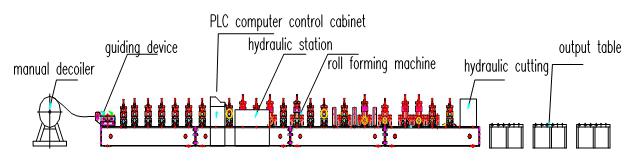

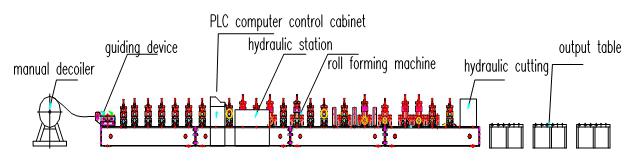

FLOW CHART

APPLICATION

APPLICATION

This type of panel is the 1990s world most prevailing roofing panel,selflock fasteners with buckle and edgefixed are all hidden.There is no screw outside of the roofing.Installing swift and convenient,having good section characteristic,its life is raised by more than 2 times than ordinary.There is no seepage definitely,suitable for all roofing,stock the over the past several years main regeneration product.Cooperated with roll forming machine of curve,it can produce roofing system with skeleton.

1.Manual decoiler: manual decoil, passitive expansion

3.Decoiler capacity: 5T

4.Machine stand: welded by steel structure, shot blast after welding, get rid of inside stress

5.Motor power of forming machine:7.5KW

6.Motor power of hydraulic station:3KW

7.Roll stand:24 stations

8.Forming speed:12m/min

9.Material of roller:high-grade 40Cr alloy steel

10.The surface of roller coating chrome:single surface 0.05mm

11.Type of forming machine: wallboard type chain transmission

12.Bearing guard: ¢50

13.Diameter of shaft: ¢75mm

14.Chain: 16A

15.type of cutting:hydraulic cutting

16.Material of cutting blade: Cr12, Quenching hardness HRC58°-62°

17.Thickness of steel coil: 0.4-0.8mm

18.Panel width of feeding: 1000mm

19.Tolerance of length:10m±2mm

20.Specific size of profile: conform to roll forming panel GB/T12755-2008 standard used for china construction

21.Form of guiding with feeding station:side trolley type

22.Transducer: Holip (Danfoss)

23.Computer adopts PLC,OMRON Series

24.Hydraulic systemic working pressure: 12Mpa

25.Computer control system: whole machine adopts industrial computer PLC control, operating board adopts Xinjie OP320A

26.Output table: roller type

Products

- Continuous Sandwich Panel Production Line

- Discontinuous Sandwich Panel Production Iine

-

Roll Forming Machine

- Roof & Wall & Door Sheet Roll Forming Machine

- Deck Floor Roll Forming Machine

- C & Z Purlin Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Downpipe Roll Forming Machine

- Box Beam Roll Forming Machine

- Folding, Shearing & Bending Machines

- Steel Springboard Roll Forming Machine

- Steel Sheet Pile Roll Forming Machine

- No-girder And Columniation Curve Roll Forming Machine

- Slitting & Cut to length line

- PU Raw Material

TOP