More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut To Length Line, etc.

Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer.

We always keep strong faith in “Thinking for what customer think”.

Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales”

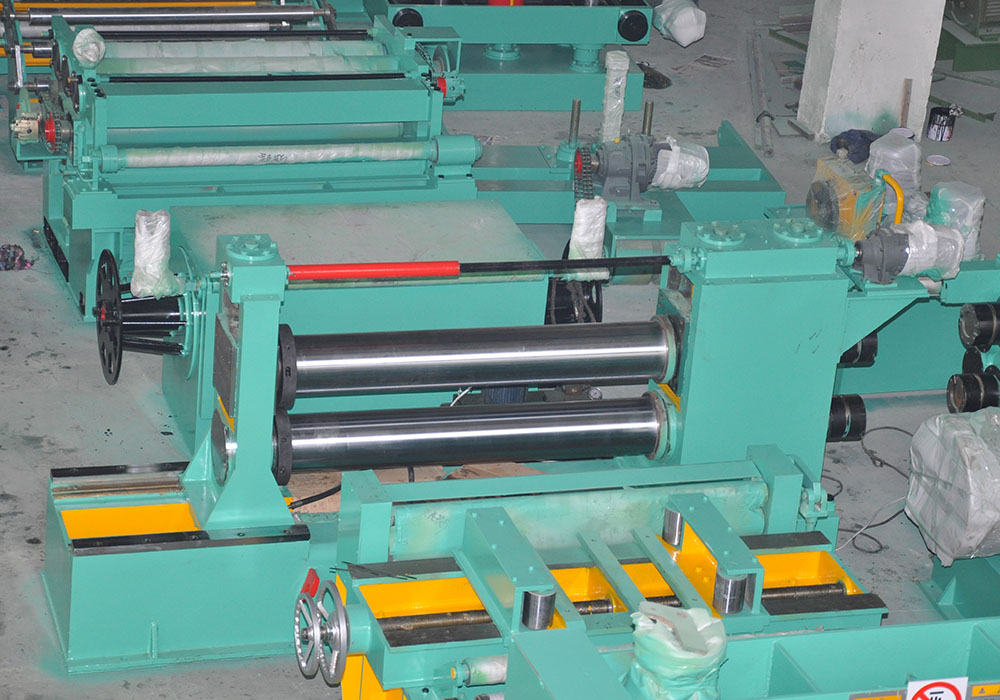

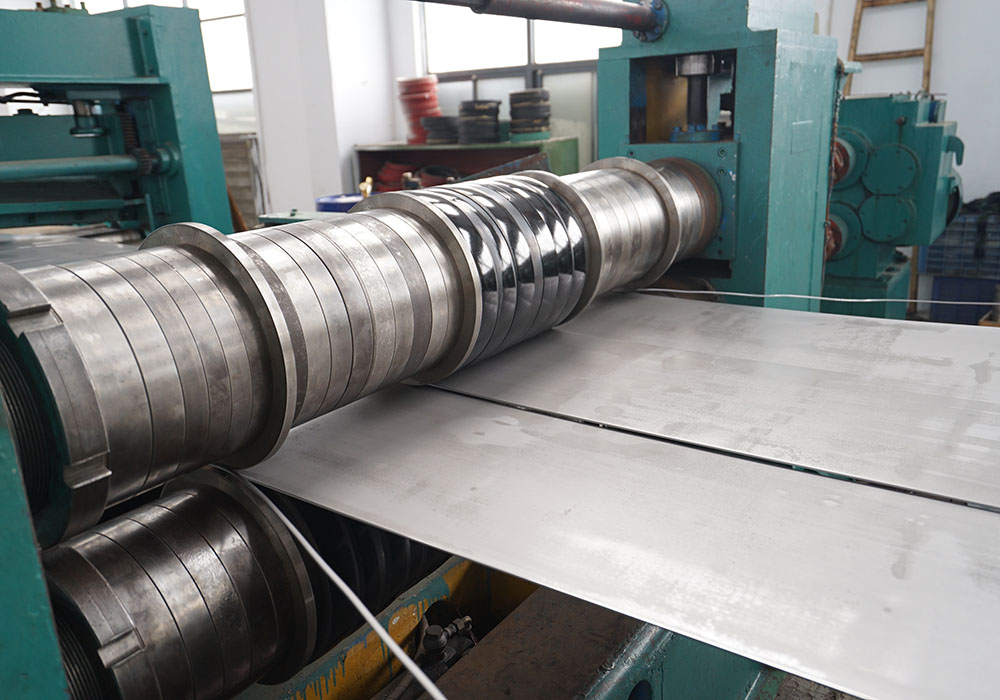

HR/pickling coil slitting line is used for coil with different specifications, through uncoiling-slitting-recoiling to needed width coil for the application of all kinds field.It is consists of uncoiler, feeder, pinch, pre-leveler, cropping shear, slitter, scrap winder and recoiler, etc. It is used for slitting the wide raw coil into narrow strips in order to prepare material for subsequent processes as milling, pipe welding, cold forming, punch forming, etc. Moreover, this line can also slit various non ferrous metal coils by changing slitting tools of different materials.

This line is reasonable in layout, easy operation, high level of automation, high productivity .

The machine performance has reached the international standard. This slitting line series coil thickness range can be from 1.0mm to 8.0mm and coil width can be from 900mm to 2000mm,all these size steel coils are produced with large output, best quality and high precision.Our customized machines are also can be used for different processed material and meet nearly all applications.

Specification of Coil Slitting Line

|

Model |

TMS6X2000 |

TMS8X2000 |

|

Coil Thickness(mm) |

1.0-6.0 |

2.0-8.0 |

|

Coil Width(mm) |

900-2000 |

900-2000 |

|

No. of Strips |

2-10 |

2-8 |

|

Line Speed(m/min) |

0-50 |

0-40 |

|

Coil Weight(T) |

30 |

30 |

|

Finish Strip Width(mm) |

≥50 |

≥70 |

|

Occupied Area(m) |

28X11 |

30X11 |

|

Power(kw) |

320 |

340 |

|

Main Shaft Dia(mm) |

φ260 |

φ300 |

|

Product ( Steel Slitting Line) Process Flow: |

|

Charging—uncoiling—pressing and guiding—pinch preleveler—scrap shear—transitional worktable —guiding—slitting—scrap winding—hydraulic loop bridge —pre-separating—damping pressing—dividing—recoiling—manual baling—discharging. |

1.Hydraulic load car

1.Hydraulic load car  2.Uncoiler

2.Uncoiler 3.Shearing machine

3.Shearing machine 4.Hydraluic loop bridge

4.Hydraluic loop bridge 5.Guiding

5.Guiding 6.Slitting

6.Slitting  7.Scrap winding

7.Scrap winding  8.Damping pressing

8.Damping pressing 9.Recoiler

9.Recoiler