Industrial Falling Film Evaporator

Projects information: Brine treatment, RO waste, ZLD system, fish meal production, chemicals crystallization, milk/stick water/ tomato paste/mango juice/orange juice/ Garlic water concentration etc.

Processing capacity: 50kg/hr, 100kg/hr, 300kg/hr, 500kg/hr, 1t/hr, 3 T / hr , 5T / hr , 10 T / hr ,15 T / hr , 20 T/hr, 25T/hr

Installed Projects: Vietnam / China / the Philippines /Indonesia / America/ Hungary ect.

Introduction for the machine

The combination of tube type, plate type and tube plate can be used.

MVR mechanical compression and TVR steam compression technology can be added.

Scope of application

Falling film type single, double, triple, fourth, fifth, Sixth, seventh, eighth efficiency, effect evaporator, suitable for evaporation and concentration in milk, starch, glucose, xylose, pharmaceutical, chemical, biological engineering, environmental engineering, waste recycling and other industries, especially suitable for easy scaling easy evaporation strong or heat sensitive materials, including plate, pipe, tube plate combination, can join the MVR, the energy-saving technology of TVR device.

System components

Evaporator, separator, condenser, vacuum and discharging system, delivery pump, PLC, electrical appliance and instruments, valves, pipelines etc.

Multi-effect evaporation concentration technology

The Live steam as the thermal energy for heating the first effect evaporator then generates secondary vapor which drawn into the second effect evaporator and so on. The multiple evaporators attached to form the whole multiple effect evaporation system. The latent heat will be recycled and reused, thus reducing the energy consumption and enhance thermal efficiency.

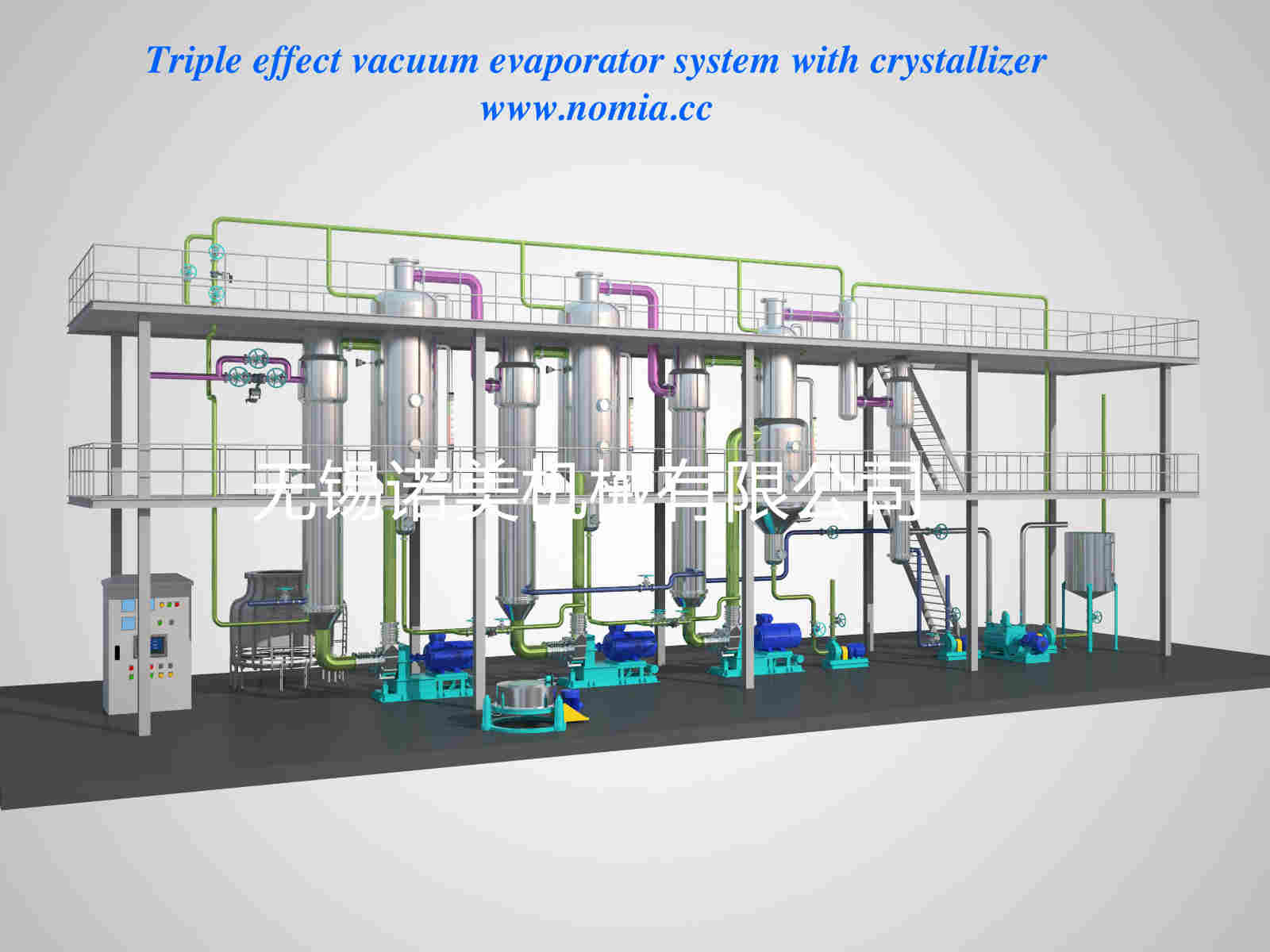

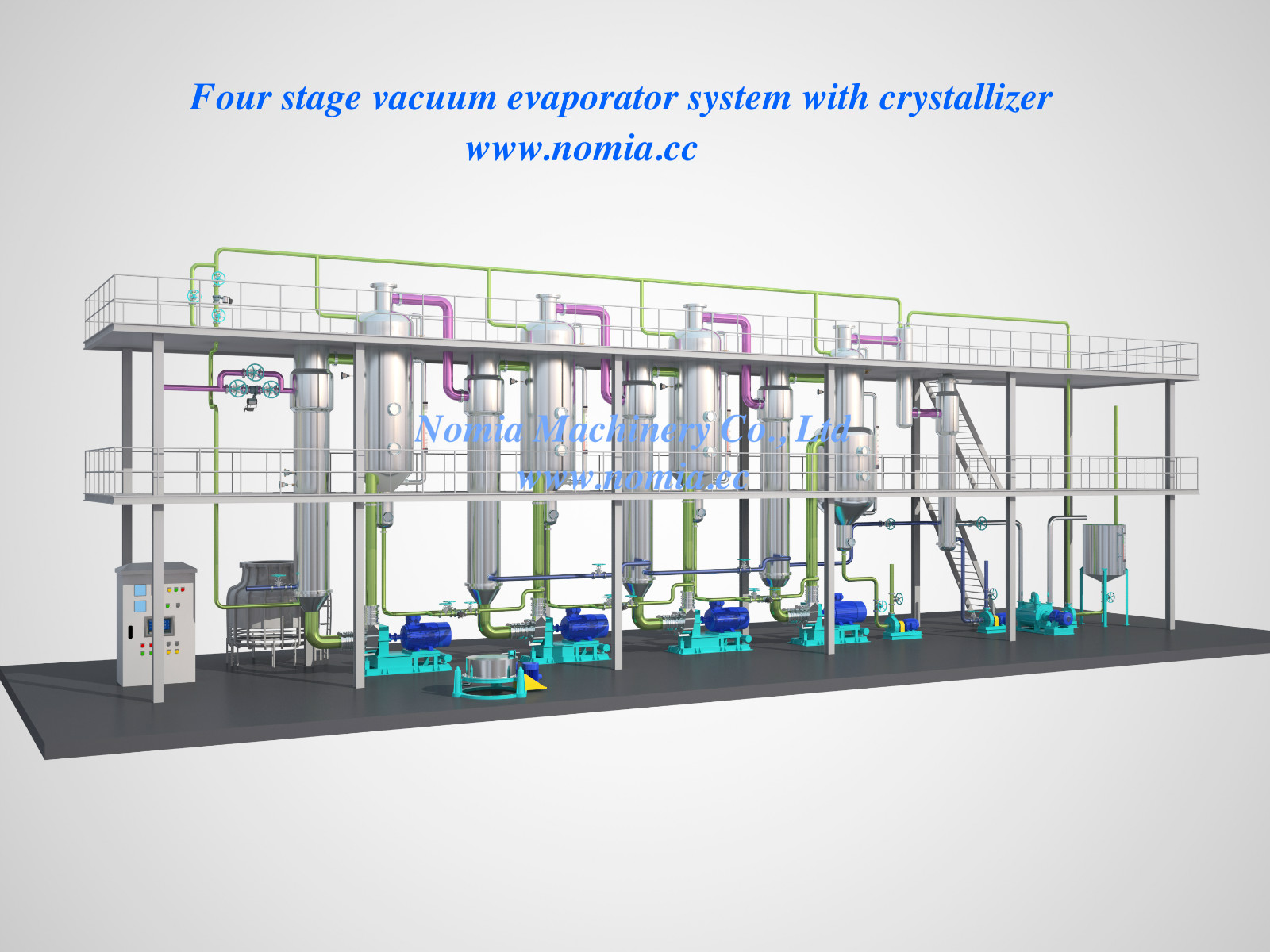

Reference diagrams

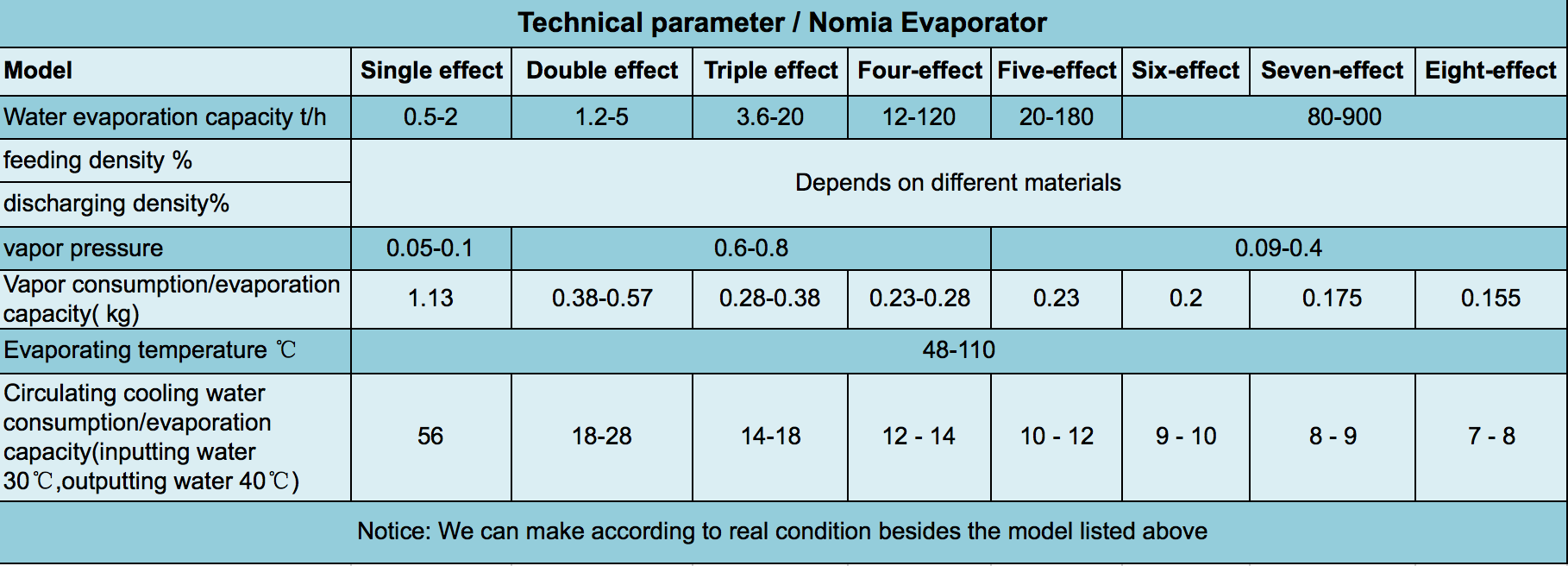

Technical parameter

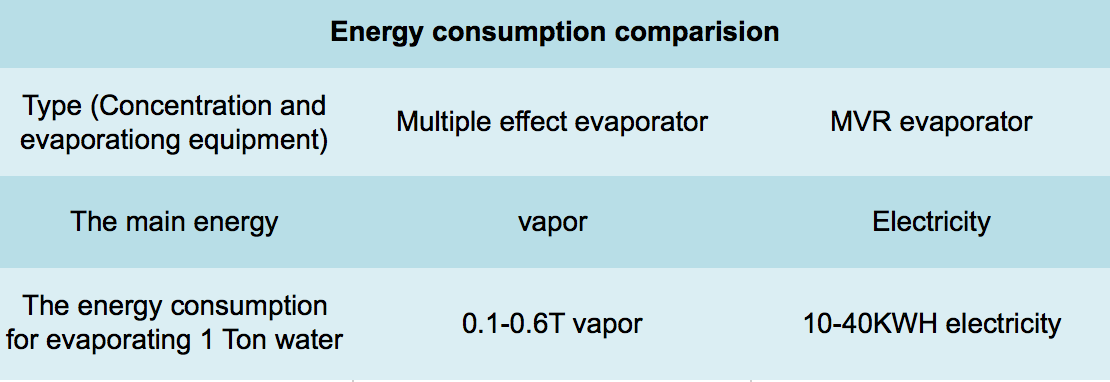

Energy Consumption

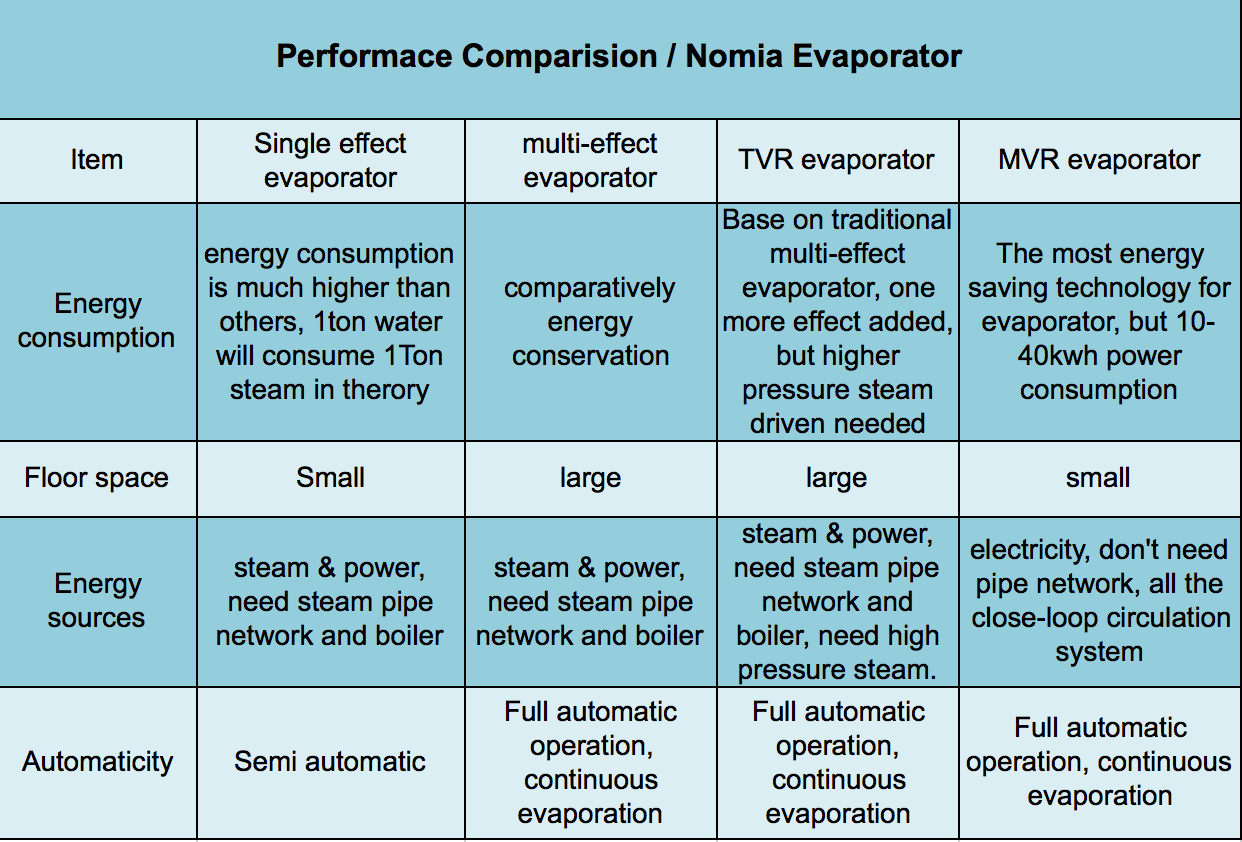

Evaporator performance

Evaporator selection notice

1. compared with electricity and vapor supply cost ahead of time.- 2. MVR invest more than multi-effect evaporator at the early stage, but the cost shall be covered after 300days service.

- 3. The evaporators are custom-built according to feeding liquid and real situation, Please contact us to consult about the design, manufacture, installation, commissioning etc.