MIC- Automatic in-line catch cap machine

87

Share

Brief introduction

Characteristics

Parameter

configuration

This machine adopts PLC programmable control, In order to achieve data storage.

Using electrical and pneumatic control machine running, high Stability. A positioning device, capping standard, Easy to operate. Reach GMP.

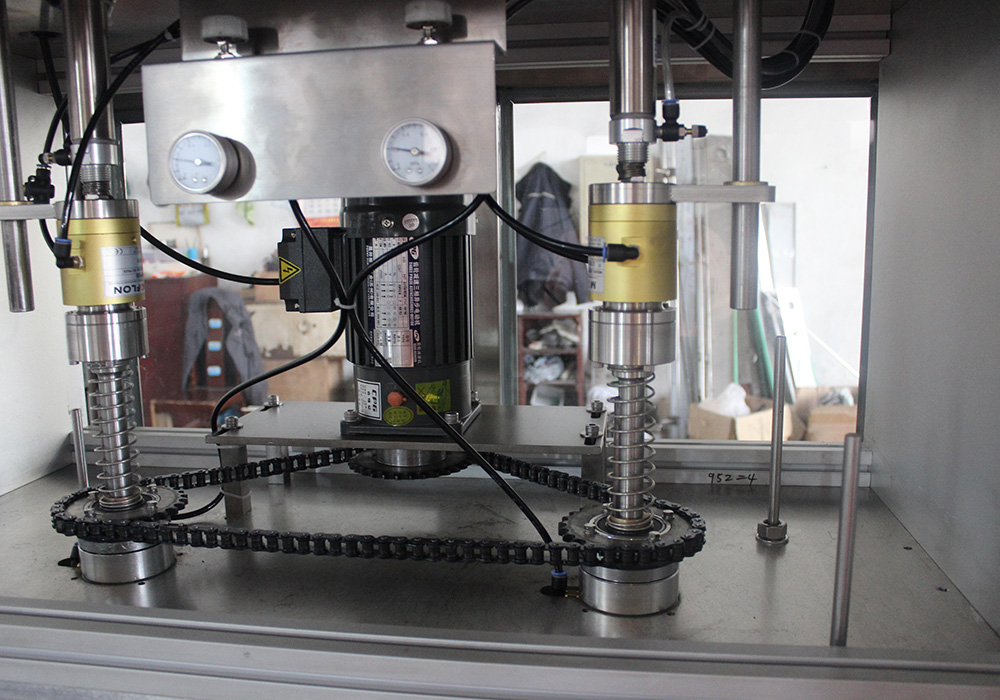

1. This machine is special designed for screw detergents bottle cap. When the bottle and cap changed, no need to replace parts.

2. Just change the screw capping head. And screw cap rate is high, fast speed, easy operation and maintance.

3. This is specifically for special cover (such as rotary force) and custom. It adopts frequency control of motor speed. The machine main parts adopt high quality stainless steel, and meet GMP standard

| Screw Capping Head | 4 Heads |

| Application Bottle | Various sizes of round bottles, square bottles (barrels), flat bottle (barrels) and shaped bottles (barrels) ,detergents bottle cap |

| Application Cap Diameter | Φ70—Φ110mm |

| Production Speed | 5000bottles/hour |

| Voltage | 220v/380v |

| Power | 5.0KW |

| Work Pressure | 0.55Mpa-0.65Mpa |

| Size | 2000mm × 950mm× 2100mm |

| Weight | 500 kg |

| PLC | Schneider France |

| Touch Screen | Canada xinjie the color screen |

| Frequency Converter | Schneider Electric |

| Solenoid Valve | AIRTAC |

| Gas Source | Taiwan AIRTAC |

| Photovoltaic Systems | Japan OPTEX |

| Inverter | Schneider France |

| Air Cylinder | AIRTAC |

| Machine Material | SUS 304 |

TOP