An aluminum tube filling and sealing machine is mainly used for aluminum tube filling and sealing.

It has been widely used in the fields of pharmacy, cosmetic, food and chemical etc.

This machine function is:

1. Consists of tube feeding system, orientation system, filling system, internal-heating system, outside heating system, Sealing and batching system, end cutting system, ejection system.

2. Adopt PLC, photo sensor, rotary plate controlling system.

3. Adopts slot wheel dividing system to drive the turntable to do intermittent movement

4. Filling measurement is accurate. Heating time is stable and adjustable. Sealed tail looks pretty and neat and the trimming is very tidy.

5. This machine has stable performance and work without any noise and pollution.

6. The part which is contact with the filling material is made of high-quality stainless steels. The parts which need to clean are made of quick-change device that is removable and convenient for washing.

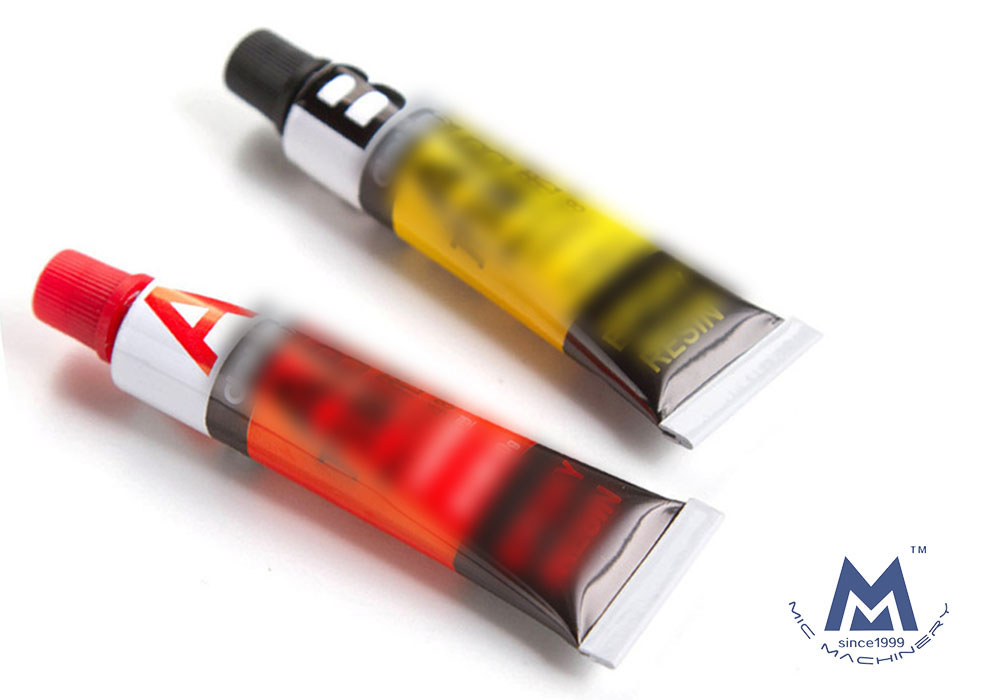

This MIC-L60-I AUTO ALUMINUM TUBE FILLING & SEALING MACHINE WITH MATERIAL PRESSING MACHINE is pneumatic controlled, with 1 filling head and a drum press. It has total 12 positions and it feeds the tube into a rotary indexing table, orients the tube then fills and seals with either heat seal and trim, or fold and crimp for metal tubes. Suitable for a wide range of applications, tube filling and sealing equipment can fill creams, lotions, food products, pharmaceuticals, greases, gels, glues, pastes, and even, on occasion, powders. All of our automatic tube filling and sealing machines include automatic tube loading, orientation, filling, sealing, and coding for plastic or metal tubes with speed ranges from 30 to 80 tubes per minute.

About the machine use problem, after the sales,

we will take video for:

1. how to connect the power

2. how to operate the machine

3. how to maintain the machine and how often to do it

4. how to adjust machine to different bottle or material.

Thank you for the reading this article,

you can also check for:

→ Our machine lately export news ←

|

Weight |

1200 Kg |

|

Dimension |

1900*1400*2000mm |

|

Power |

220V/50Hz |

|

Motor |

2.2 Kw |

|

Filling Quantity |

3-20ml,15-75ml, 75-250ml |

|

Capacity |

50-60 tpm |

|

Name |

Brand |

|

Framework |

SUS 304 Stainless Steel |

|

Junction Box |

CZ Explosion-proof |

|

Button |

CZ Explosion-proof |

|

Main Servo Motor |

Siemens (Explosion-proof One Zone) |

|

PLC |

Siemens |

|

Stepping Motor |

Siemens (Explosion-proof One Zone) |

|

Stepping Drive |

Siemens |

|

Color Mark Sensor |

P+F, Germany |

|

Approch Switch |

P+F, Germany |

|

Media Relay |

Siemens |

|

Magnetic Valve |

SMC, Japan |

|

Divider |

Yddex, Shangdong |

|

Pneumatic Elements |

SMC, Japan |

|

Servo Pump for Filling |

Micmachinery |

|

Bearings |

FAG, Germany |