Semiautomatic bottle blow molding machine

1. Adopting double crank to adjust mould ,heavy locking mould, stable and fast ,Adopt infrared oven to heat the perform ,the perform rotated and heated equally.

2. The air system has been divided into two parts: pneumatic action part and bottle blow part to meet the different requirements for the action and blow .It can provide sufficient and steady high pressure for blowing large irregular shaped bottles.

3. The machine is also equipped with muffler and oiling system to lubricate the mechanical part of the machine.

4. The machine can be operated in the step-by-step mode and the semi-auto mode.

5. The machine is small with low investment, easy and safe to operate.

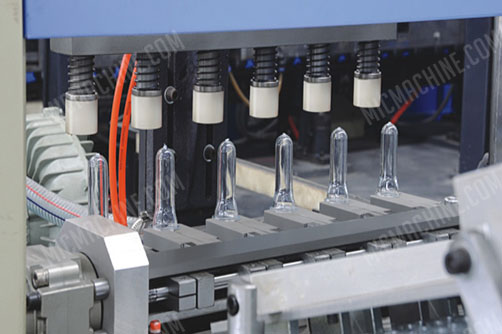

Automatic blow molding machine

It is widely used to produce the carbonated bottle, mineral water bottle, pesticide bottle, oil bottle, cosmetics bottle etc.

1. Stable performance with advanced PLC.

2. Conveying preforms automatically with conveyor.3. Strong penetrability and swift distribution of the heater by letting the bottles rotate by itself and revolute in the rails simultaneously in the infrared pre-heater.

4. Strong clamping force with high pressure and double crank links to lock the mold.

5. Low cost, high efficiency, easy operation, easy maintenance, with automatic technological process.

6. Ideal effect of the chilling with the chilling system.

7. Easy installation and starting

8. Low rejection rate: less than 0.2 percent.

|

Semiautomatic bottle blow molding machine |

||

|---|---|---|

|

Container |

Product material |

PET |

|

Volume |

100ML-5L |

|

|

Theoretical output |

500-1000PCS/H(base on 0.5L) |

|

|

|

Preform length |

15mm-400mm |

|

Preform inner diameter |

Φ10mm-160mm |

|

|

Moulding |

Max. mould plate Dimension(L x W) |

400x460mm |

|

Max. mould thickness |

300mm |

|

|

Clamping force |

65KN |

|

|

Mould opening stroke |

280mm |

|

|

Machine size and weight |

Main machine (L x W x H) |

175*67*186cm |

|

Main machine weight |

600Kg |

|

|

Heater (L x W x H) |

187*63*145cm |

|

|

Heater weight |

250Kg |

|

|

Power |

17.5kw |

|

|

Automatic blow molding machine |

||

|

Productivity |

Depend on bottle design |

4500-5000PCS/H |

|

Product type |

Body diameter |

≤90mm |

|

Height |

≤320mm |

|

|

|

Neck diameter |

28mm |

|

Mold |

Cavity |

8cavities |

|

Mold thick |

240mm |

|

|

Main machine power |

Electrical source power |

380v 3Phase /220v 3Phase 50/60HZ |

|

Rated Power |

66kw |

|

|

Really use power |

28kw |

|

|

Air source |

LP air compressor |

3.0m3/min 1.0MPa |

|

HP air compressor |

6.0m3/min 4.0MPa x 3 |

|

|

Power full Air Dryer |

15.0m3/min 4.0MPa |

|

|

Normal Air Dryer |

15.0m3/min 4.0MPa |

|

|

Air Tank |

2.0 m3 4.0MPa |

|

|

Mold Temperature control |

18kw |

|

|

Low air filter |

3.0m3/min 1.0MPa |

|

|

Cooling water |

Cooling water |

60L/min |

|

Size |

L*W*H |

6500*4000*2200mm |

|

Weight |

6100kg |

|

|

Auxiliary equipment(preform unscrambler) |

L*W*H |

2300*1500*2480mm |

|

Weight |

350kg |

|

|

Resin available |

/ |

PET |