JM can design and manufacturing special products according to the drawings or samples for your requirements

|

|

|

|

JMPM-001 |

JMPM-002 |

JMPM-003 |

|

Used on the car & aircraft |

Used on the car & aircraft |

Used on the car & aircraft |

|

|

|

|

JMPM-004 |

JMPM-005 |

JMPM-006 |

|

Used on the car & aircraft |

Used on the car & aircraft |

Used on the car & aircraft |

|

|

|

|

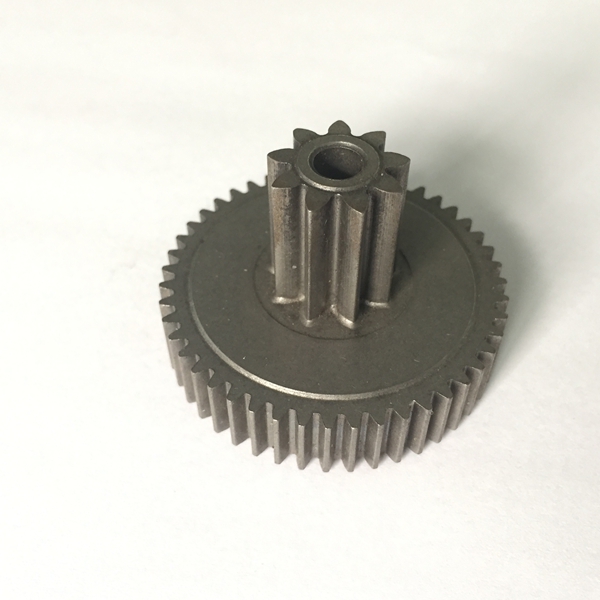

JMPM-007 |

JMPM-008 |

JMPM-009 |

|

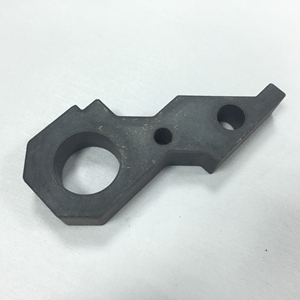

Used on the gun drill |

Used on the gun drill |

Used on the gun drill |

|

|

|

|

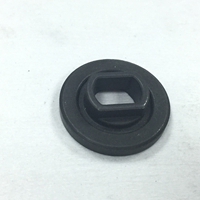

JMPM-010 |

JMPM-011 |

JMPM-012 |

|

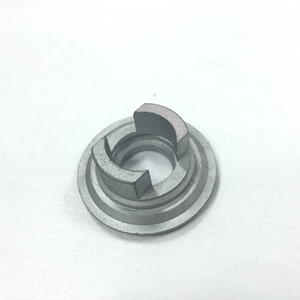

Used on the elevator |

Used on the elevator |

Used on the elevator |

|

|

|

|

|

JMPM-013 |

JMPM-014 |

JMPM-015 |

JMPM-016 |

|

|

|

|

|

|

|

|

|

|

JMPM-017 |

JMPM-018 |

JMPM-019 |

JMPM-020 |

|

|

|

|

|

|

|

|

|

|

JMPM-021 |

JMPM-022 |

JMPM-023 |

JMPM-024 |

|

|

|

|

|

|

|

|

|

|

JMPM-025 |

JMPM-026 |

JMPM-027 |

JMPM-028 |

|

|

|

|

|

|

|

|

|

|

JMPM-029 |

JMPM-030 |

JMPM-031 |

|

|

|

|

|

|

|

Powder metallurgy |

|

|

Material: |

Carbon steel, stainless steel, iron,copper,brass, aluminum |

|

Surface treatment: |

Zinc, nickel, chrome, siver, gold plating, QPQ, painting, printing, anodizing, powder coating, black oxide, full hardening, case hardening, induction hardening |

|

Tolerance: |

We do according to customer drawing, if we find the tolerance after careful studying is hard to achieve, we will quote with conditions. |

|

Inspection machines: |

Projector, CMM, hardness tester, roughness tester, salt spray tester, tensile strength tester, caliper, micrometer, height gauge, thread ring and plug gauge, pin gauge,etc. |

|

Drawing format: |

PDF, CAD in DGW or DXF format, 3D in IGES or STEP format, Picture format. |

|

Application: |

Automotive, motorcycles, textile machinery, industrial sewing machines, power tools, hardware tools, Electrical, engineering machinery, etc. |

Description of powder metallurgy process: Powder metallurgy is used to produce metal powder or produce metal materials, composite materials and various products by using metal powder (or a mixture of metal powder and non-metal powder) as raw material through forming and sintering. Currently, powder metallurgy process has been widely used in transportation, machinery, electronics, aerospace, weapons, biological, new energy, information and nuclear industries, becoming one of the most dynamic branches in new material science.

Advantages: It enjoys a series of advantages including significant energy

saving, material saving, good performance, high precision and good stability,

very suitable for mass production. It

is can be applied to process materials and complex parts cannot be produced by

traditional casting method and machining method. The powder metallurgy process

can produce porous, half density or full density material and products

directly, such as oil bearing, gear, cam, guide rod and cutter, etc. It is a

kind of process without cutting.

Process order:

(1) Producing powder. The production process of powder includes producing of powder, mixing of powder, and other steps. To improve the formability and plasticity of powder, such plasticizers as oil, rubber or paraffin are usually added.

(2) Compression molding. Press the power to required shape under pressure of 15-600MPa.

(3) Sintering. Spark Plasma Sintering (SPS) is conducted in high temperature furnace or vacuum furnace with protective atmosphere. Different from metal melting, sintering requires that at least one element shall maintain solid state. During the sintering process, powder particles become metallurgical products with certain porosity through a series of physical and chemical processes including diffusion, recrystallization, fusion welding, chemical combination, and dissolution.

(4) Post processing. Generally, the sintered parts can be used directly. But some parts having high requirements of precision, hardness and wear resistance shall be conducted with post-sintering processing. The post-processing includes precision pressing, rolling, extruding, quenching, surface hardening, oil immersion, and infiltration, etc.