PP Pleated Filter Cartridges

1

LPPF filter cartridges are constructed of multilayer polypropylene, featuring high flow rates, broad chemical compatibility and high dirt holding capacity. These filters are ideal for removing particulate and colloidal contaminants in vaccines filtration.

Features and Benefits

● Superior dirt-holding capacity

● Reliable retention of particulates

● Broad chemical compatibility

Quality

● Cartridges produced in a controlled environment

● Manufactured according to ISO9001 certified Quality Management System

Specification

LPPF Multi-layer Filter Cartridge for Vaccines

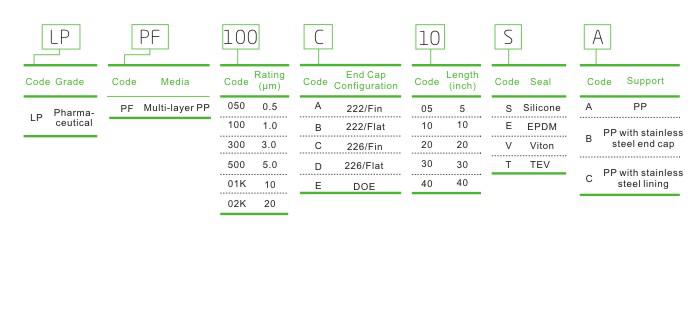

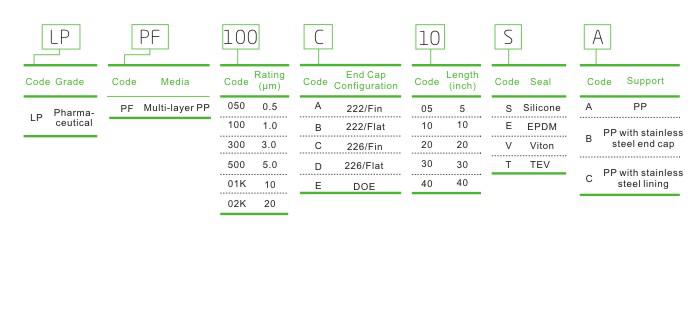

Ordering Information

LPPF Multi-layer Filter Cartridge for Vaccines

Share

LPPF filter cartridges are constructed of multilayer polypropylene, featuring high flow rates, broad chemical compatibility and high dirt holding capacity. These filters are ideal for removing particulate and colloidal contaminants in vaccines filtration.

Features and Benefits

● Superior dirt-holding capacity

● Reliable retention of particulates

● Broad chemical compatibility

Quality

● Cartridges produced in a controlled environment

● Manufactured according to ISO9001 certified Quality Management System

Specification

LPPF Multi-layer Filter Cartridge for Vaccines

| Materials of Construction | |

| Filter Media | Multi-layer PP |

| Support | PP |

| Core, Cage and Drainage | PP |

| End Caps | PP |

| O-rings/Gasket | Silicone/EPDM/Viton/TEV |

| Sealing Technology | Thermal Bonding, No Adhesives |

| Dimensions | |

| Diameter | Φ68 |

| Length | 5 inch, 10 inch, 20 inch, 30 inch, 40 inch |

| Filtration Area, ft2 | |

| 2.1~3.2 per 10-inch element | |

| Pore Size, μm | |

| 0.5, 1.0, 3.0, 5.0, 10, 20 | |

| Maximum Differential Pressure | |

| Forward: 4.2 bar @ 23 ℃; 1.5 bar @ 85 ℃ | |

| Particle Removal Efficiency (%) | |

| ≥ 90 | |

| Extractables, per 10-inch cartridge | |

| ≤ 50 mg after 24-h soak in water | |

| Toxicity | |

| Component materials meet GB/T 14233.2of Chinese National Standard for Safety Tests. | |

| TOC | |

| < 500 ppb after a water flush of 60 liters per 10-inch cartridge | |

| Sterilization | |

| Support steam-in-place sterilization or autoclave at 123℃ | |

| Oxidizable Substances | |

| Meets the criteria of Chinese Pharmacopoeia 2010, volume Ⅱ for purified water. | |

| Bacterial Endotoxins | |

| < 0.25 EU/ml as determined by the LAL test | |

Ordering Information

LPPF Multi-layer Filter Cartridge for Vaccines

TOP