Performance characteristics:

1.With optional programmed controller system Chinese famous ESTUN E200PS or Netherlands DELEM DAC310

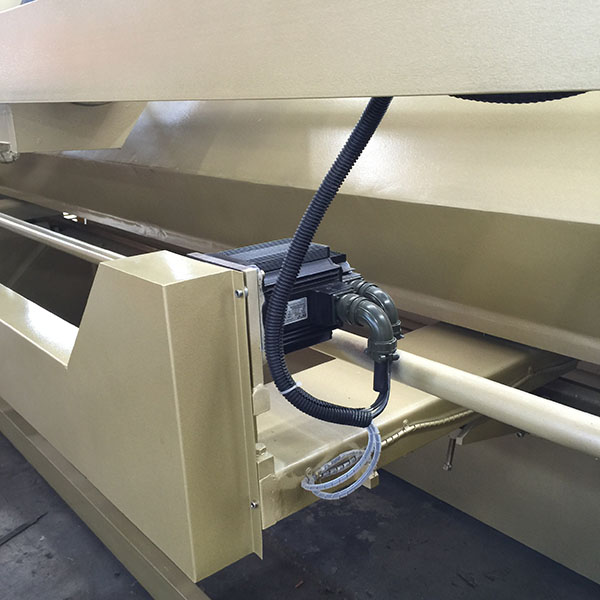

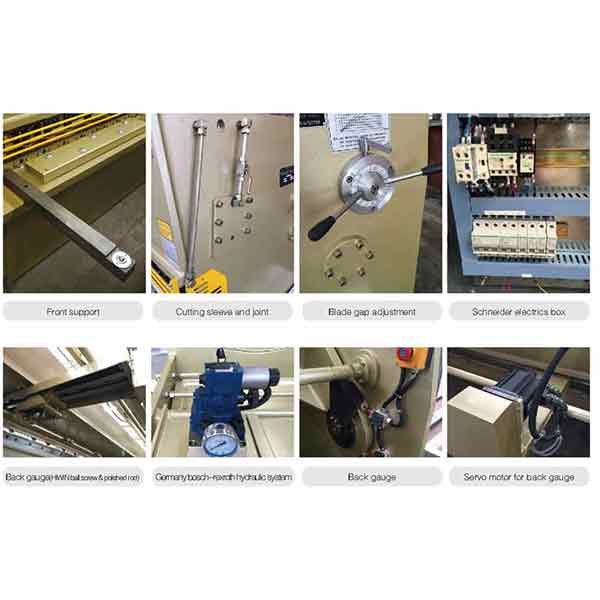

2.Adopt linear guide,ball screw and servo motor driven back gauge to ensure the accuracy

3.All main parts of this machine such as worktable, wallboard,top blade rest, etc. are adopting steel plate welded structure

4.Hydraulic transmission cutting,

5.Nitrogen cylinder driven returning stroke with stable operation, low noise, and well rigidity

6.With electric driven back stop structure and mechanical worm wheel-worm transmission control with low noise and high precision

7.Adjustment blade gap board to adapt different thickness plates

8.Safety protection fence and warning tape

Our machine advantages:

1)Straightness:Within 3 meter error within 0.10mm

In the same industry product error 0.5-1mm

2)Cutting times 50% faster than the same industry.

For example:4*2500 shearing machine,our company product 30 times/min,in the same industry product only 12 times/min.

3)Machine body intensity,high precision processing equipment,holistic processing,the machine body will not be deformation in 10 years.

4)Blade material:6CrW2Si

Heat treatment: 55°-60°HB

5)Low noise,gear pump drive by hydraulic,70bd.

6)Emergency stop foot pedal increase the security protection,explosion -proof power supply switch cord.

How to choose the machine model?

The main required information is the material,cutting thickness and cutting length.

This series shear is mainly used to cut metal plates with the thickness of 0.2-30mm and different shearing length.The maximum cutting thickness is only applicable to carbon structural steel plates with the tensile strength of 450 MPa; if it is used to cut metal plates with relatively high tensile strength such as manganese steel, stainless steel, etc., the maximum shearing thickness shall be less. Thus, when using the shear, the thickness of plates shall be strictly controlled by the operators themselves in accordance with the value of tensile strength of plates.As the cutting angle of this series is fixed,it can not be adjusted according to big thickness difference,usually it is widely used with the thickness of 0.2-16mm.Above 16mm thickness you can choose Q11Y series.

Then,according to the thickness of different material,you can choose the suitable length for yourself.With all of these you can go to the technical parameters table to find the right model and details.

If you need further help from us,please contact us through our contact information.

| Model | Cutting thickness(mm) | Cutting width(mm) | Cutting angle(°) | Back gauge range(mm) | Stroke Number(Time/min) | Main motor (KW) | Weight(kg) | Dimensions(LxWxH)(mm) |

|---|---|---|---|---|---|---|---|---|

| 4*2500 | 4 | 2500 | 1.5 | 20-400 | 16 | 5.5 | 3800 | 3000*1550*1600 |

| 4*3200 | 4 | 3200 | 1.5 | 20-600 | 13 | 7.5 | 5700 | 3850*1550*1600 |

| 4*4000 | 4 | 4000 | 1.5 | 20-600 | 10 | 7.5 | 7600 | 4500*1700*1700 |

| 4*6000 | 4 | 6000 | 1.5 | 20-600 | 8 | 11 | 17800 | 6500*2100*2300 |

| 6*2500 | 6 | 2500 | 1.5 | 20-600 | 15 | 7.5 | 5500 | 3000*1700*1650 |

| 6*3200 | 6 | 3200 | 1.5 | 20-600 | 12 | 7.5 | 6500 | 3850*1700*1650 |

| 6*4000 | 6 | 4000 | 1.5 | 20-600 | 9 | 7.5 | 8200 | 4600*1850*1700 |

| 6*6000 | 6 | 6000 | 1.5 | 20-600 | 5 | 15 | 20500 | 6500*2100*2300 |

| 8*2500 | 8 | 2500 | 1.5 | 20-600 | 14 | 7.5 | 5800 | 3050*1700*1700 |

| 8*3200 | 8 | 3200 | 1.5 | 20-600 | 10 | 7.5 | 6800 | 3850*1700*1700 |

| 8*4000 | 8 | 4000 | 1.5 | 20-600 | 8 | 15 | 8800 | 4650*1700*1700 |

| 8*6000 | 8 | 6000 | 1.5 | 20-600 | 6 | 15 | 22500 | 6500*2100*2350 |

| 10*2500 | 10 | 2500 | 1.5 | 20-600 | 10 | 15 | 7200 | 3050*1800*1700 |

| 10*3200 | 10 | 3200 | 1.5 | 20-600 | 9 | 15 | 8500 | 3900*2000*1700 |

| 10*4000 | 10 | 4000 | 1.5 | 20-600 | 8 | 18.5 | 12500 | 4650*2100*2000 |

| 10*6000 | 10 | 6000 | 1.5 | 20-800 | 6 | 18.5 | 27500 | 6500*2100*2300 |

| 12*2500 | 12 | 2500 | 1.5 | 20-800 | 12 | 18.5 | 9800 | 3150*2050*2000 |

| 12*3200 | 12 | 3200 | 1.5 | 20-800 | 10 | 18.5 | 11600 | 3900*2150*2000 |

| 12*4000 | 12 | 4000 | 2 | 20-800 | 8 | 18.5 | 13800 | 4700*2150*2100 |

| 12*5000 | 12 | 5000 | 2 | 20-800 | 6 | 22 | 19000 | 5800*2450*2400 |

| 12*6000 | 12 | 6000 | 2 | 20-800 | 5 | 22 | 31000 | 6900*2600*2700 |

| 12*8000 | 12 | 8000 | 1.75 | 20-800 | 4-6 | 22 | 50000 | 8600*3250*3200 |

| 16*2500 | 16 | 2500 | 2 | 20-800 | 10 | 18.5 | 11000 | 3150*2250*2000 |

| 16*3200 | 16 | 3200 | 2 | 20-800 | 10 | 18.5 | 12600 | 3900*2250*2000 |

| 16*4000 | 16 | 4000 | 2.5 | 20-800 | 3 | 22 | 17300 | 4650*2250*2200 |

| 16*5000 | 16 | 5000 | 2.5 | 20-800 | 6 | 30 | 24000 | 5900*2600*2700 |

| 16*6000 | 16 | 6000 | 2.5 | 20-800 | 5 | 30 | 36800 | 6900*2700*2900 |

| 20*2500 | 20 | 2500 | 2.5 | 20-800 | 8 | 30 | 14800 | 3450*2300*2500 |

| 20*3200 | 20 | 3200 | 2.5 | 20-800 | 8 | 30 | 17000 | 4150*2350*2700 |

| 20*4000 | 20 | 4000 | 2.5 | 20-800 | 5 | 30 | 23000 | 4850*2600*2800 |

| 25*2500 | 25 | 2500 | 3 | 20-800 | 8 | 37 | 19000 | 3200*2700*2900 |

| 25*3200 | 25 | 3200 | 3 | 20-800 | 5 | 37 | 23000 | 4200*2700*3000 |

| 30*2500 | 30 | 2500 | 3.5 | 20-1000 | 4 | 37 | 28000 | 3300*2900*3000 |

| 30*3200 | 30 | 3200 | 3.5 | 20-1000 | 4 | 37 | 33000 | 4200*2900*3200 |

2 Do not put your hands between upper and lower blades to avoid accidents.

3 All sundries and tolls shall not be placed on worktable to avoid from damaging blades by accidently entering edge of blades.

4 Sharpness of the edge of blades shall be checked periodically, and if the edge of blade is found blunt, grinding or changing shall be carried out in time. For grinding, it is only the thickness of blades that needs to be grinded.

5 Parts of the machine shall be periodically checked to maintain the cleanness of machine tool and its surrounding area and well insulation of the electrical wire.

6 Net type oil filter placed on the inlet port of oil pump shall be usually checked and cleaned to maintain oil transmission volume; if the oil filter is obstructed and the volume is lessened, oil pump shall sucked all oil, which will influence the service life of the oil pump and cause improper operation of the machine tool.

7 Energy accumulators shall be filled with nitrogen, but no oxygen, compressed air or other combustible gases. The special charging pipe attached to the machine tool shall be adopted to slowly fill nitrogen, and the pressure shall not be more than 8MPa.

8 Separate lubrication is adopted on the machine tool, and please refer to the figure to carry out lubrication on each lubricating points in daily work.