Rising Film Evaporator

Evaporator System components

Evaporator, separator, condenser, vacuum and discharging system, delivery pump, PLC, electrical appliance and instruments, valves, pipelines etc.

MVR evaporator system

MVR applied mechanical vapor recompression unit for compressing the secondary vapor so that recycle the secondary vapor completely in a closed-loop circulation system. As a result of the vapor compressor, temperature and pressure of the secondary vapor raised, the heat efficiency boosted. The effectiveness of live steam is equal to 30 effects of multiple effect evaporator. Thus reducing the demand for external live vapor and cooling resources, energy conservation and less pollution attained.

Application Range

The solution for concentration and crystallization.

Project information: Brine treatment, Stickwater, RO waste, ZLD system, tomato paste/mango juice/orange juice/ Garlic water concentration etc.

Processing capacity: 50kg/hr, 100kg/hr, 300kg/hr, 500kg/hr, 1t/hr, 3 T / hr , 5T / hr , 10 T / hr ,15 T / hr , 20 T/hr, 25T/hr

Installed Projects: Vietnam / China / the Philippines /Indonesia / America/ Hungary ect.

-Low requirements for the material properties, flexible for the operation

-Axial type feeding, to improve the crystallization effect

-Flow velocity in heating tubes, to improve tube wall scaling

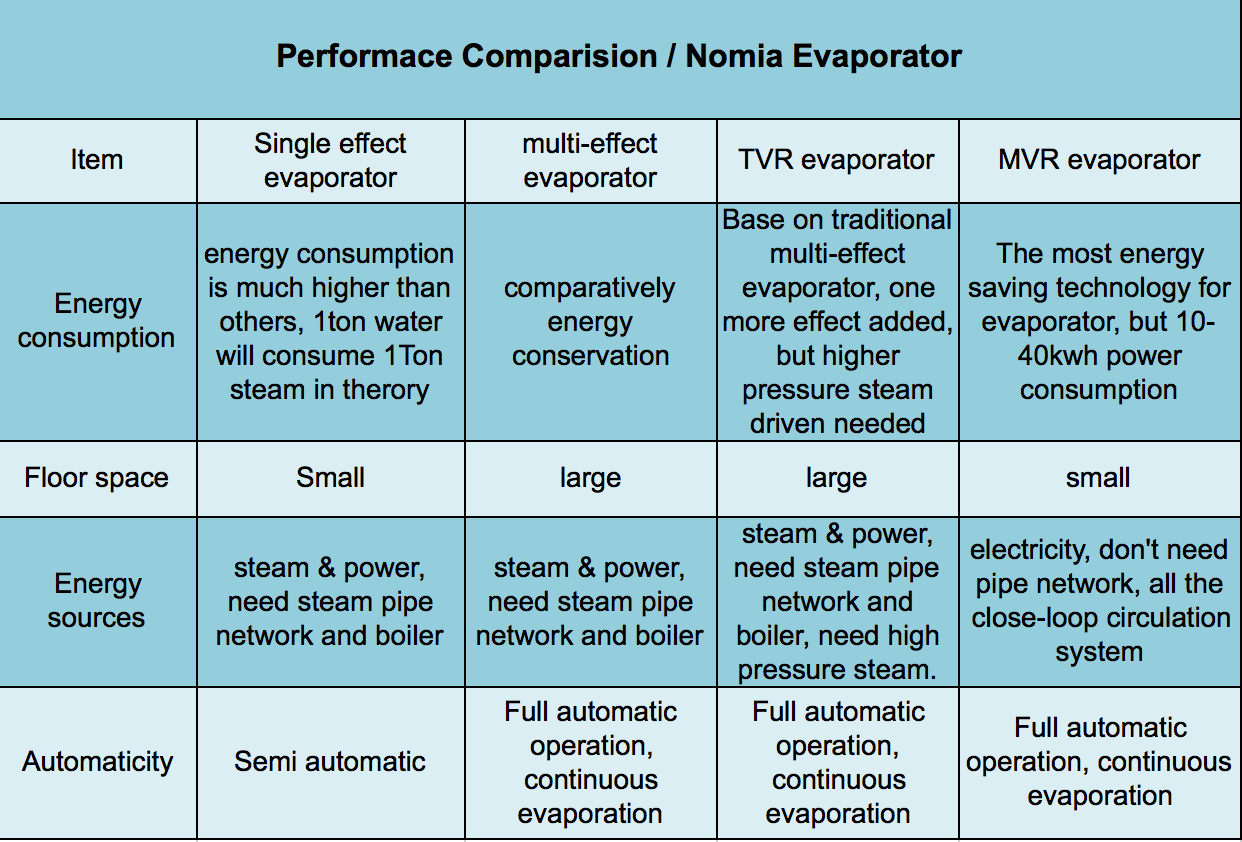

Evaporator performance

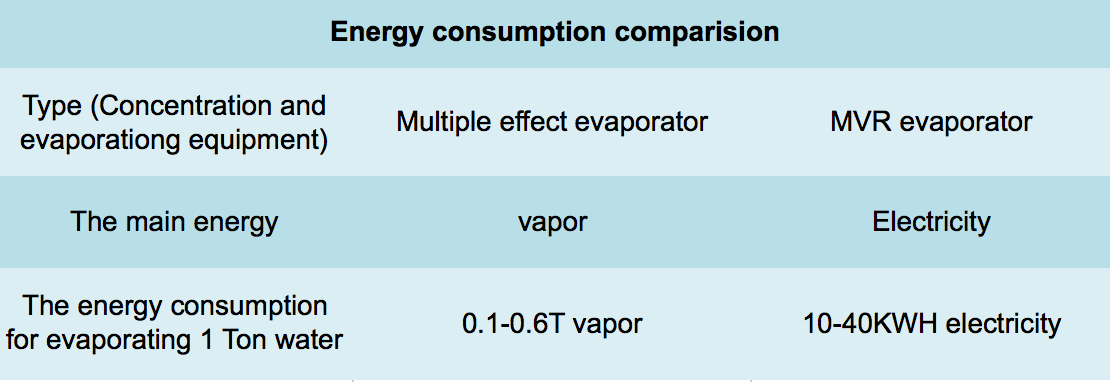

Energy Consumption

Reference image

Evaporator selection notice

1. compared with electricity and vapor supply cost ahead of time.

2. MVR invest more than multi-effect evaporator at the early stage, but the cost shall be covered after 300days service.

3. The evaporators are custom-built according to feeding liquid and real situation, Please contact us to consult about design, manufacture, installation, commissioning issues etc.