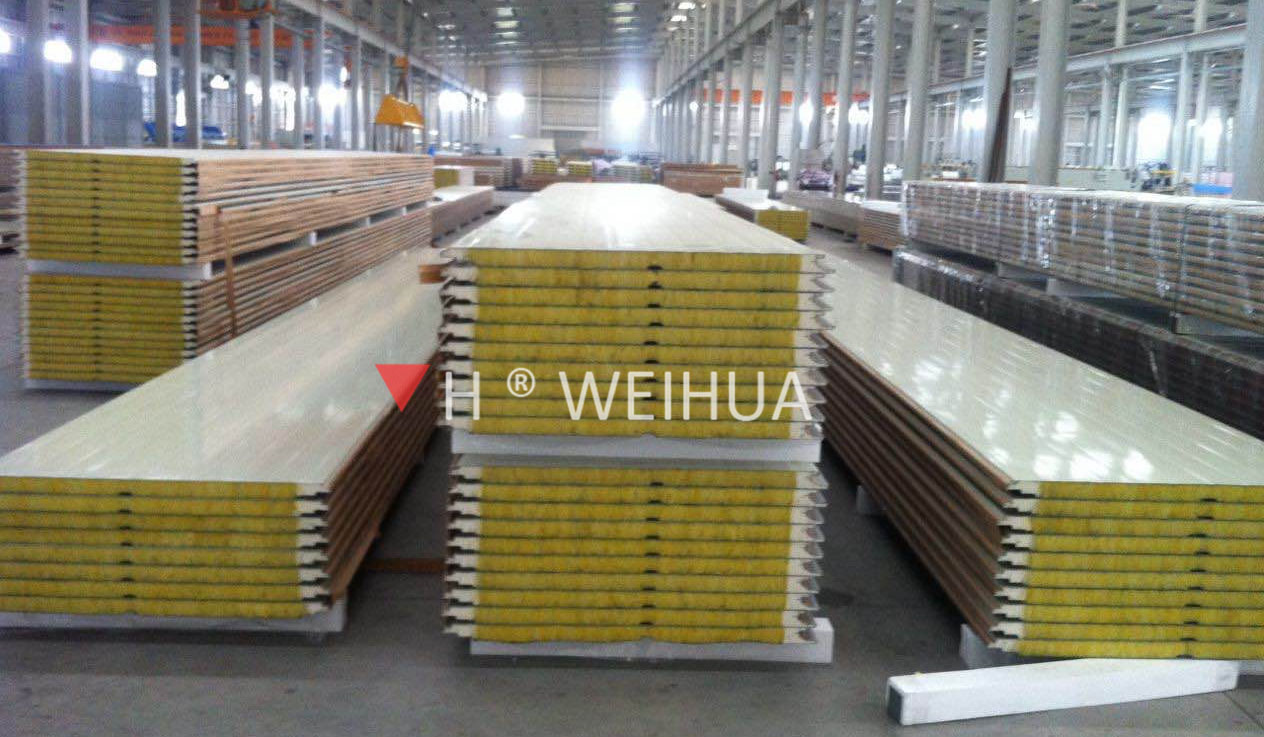

Rock Wool Sandwich Panel Production Line

1

Share

DESCRIPTION

WEIHUA'S CUSTOMER

WEIHUA'S CUSTOMER

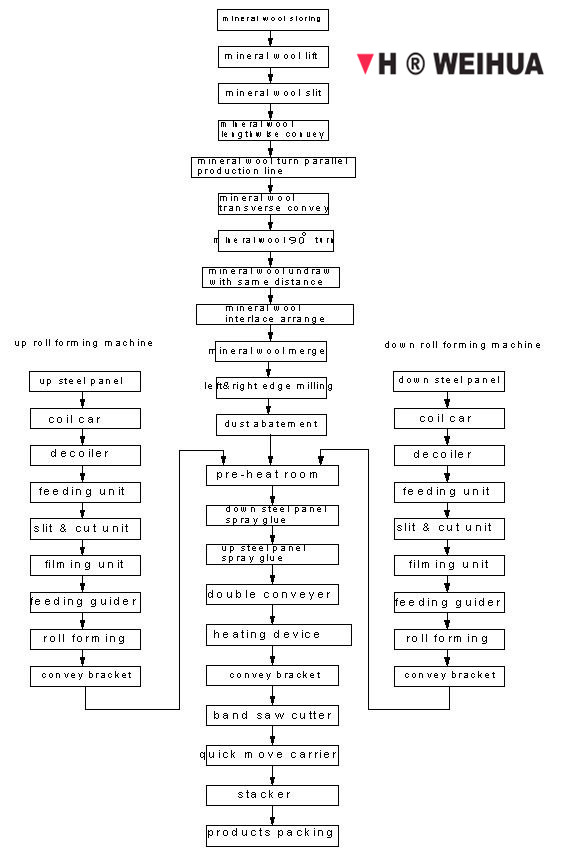

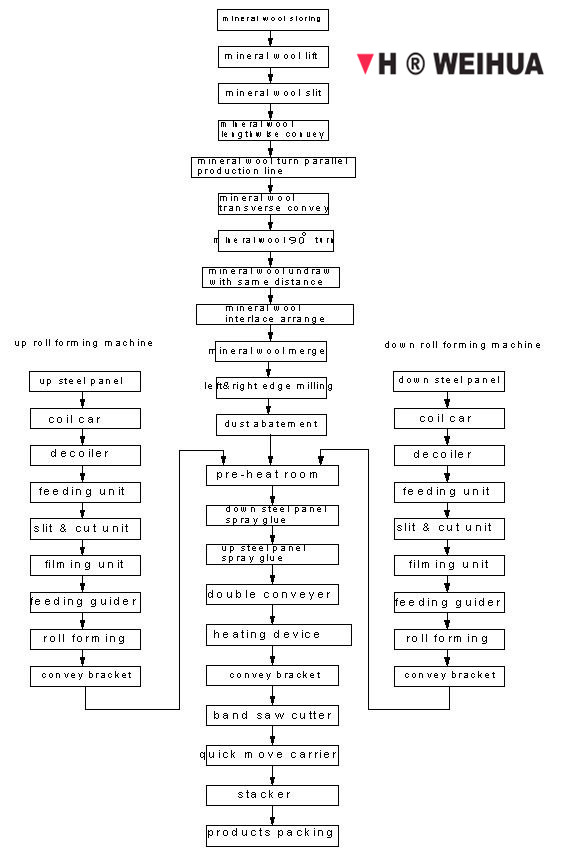

Rock wool system is used for slitting the big block rock wool into branches and conveying & turning to change the direction of fiber, thus make the rock wool blocks to meet the requirements of construction composite panels’ intensity, and then arraying, milling edge, spraying glue on up & down panels and at last cohere with the up & down steel panels. The system includes storing elevator, slitting machine, lengthways conveying, 90 degrees turning over, arraying device, joint edge milling, glue-spraying system, auto stacker for wooden pallet, dust suction machine and so on.

Rock wool glue system has two types: one is two components of ISO and polyhydric alcohols; the other type is three components of ISO, polyhydric alcohols and catalyst.

TECHNICAL PARAMETER

1)Machine speed 1:6m/min (50mm thickness*2400 length)

2)Machine speed 2:4.5m/min (50mm thickness*1800 length)

3)Glue spary weight: 180g-250g

4)The height of final composite panel:50mm,75mm,100mm,125mm,150mm,175mm,200mm

5)The max efficient width of final composite panel:1000mm

6)Rockwool strips: max 10 strips

7)The max height of the raw block rockwool: ≤105mm

8)The height tolerance of the raw block rockwool: :±2mm

9)Raw block rockwool standard: national standard

10)Raw glasswool standard: national standard

11)Rockwool weight: 80~120kg/m³

12)Glasswool weight: 64~100 kg/m³

13)Cutting blade seam width: 3.3mm

14)The length of the rockwool strip: 1.8m~2.4m

15)The tensile strength of rockwool: ≥7.5Kpa

16)The compressive strength of rockwool: ≥40Kpa

17)Hydrophobic of rockwool: ≥98%

18)Shot content of rockwool: ≤10% Grain size>0.25mm

19)The distance from glue spray point to double belt conveyor entrance: 7m

20)The efficient length of double belt conveyor:17.8m, different glue need different gelation time.( the costomer has to prepare different glue or choose three compontent glue spray equipment)

21)Environment temperature: 10-30℃

FLOW CHART

2)Machine speed 2:4.5m/min (50mm thickness*1800 length)

3)Glue spary weight: 180g-250g

4)The height of final composite panel:50mm,75mm,100mm,125mm,150mm,175mm,200mm

5)The max efficient width of final composite panel:1000mm

6)Rockwool strips: max 10 strips

7)The max height of the raw block rockwool: ≤105mm

8)The height tolerance of the raw block rockwool: :±2mm

9)Raw block rockwool standard: national standard

10)Raw glasswool standard: national standard

11)Rockwool weight: 80~120kg/m³

12)Glasswool weight: 64~100 kg/m³

13)Cutting blade seam width: 3.3mm

14)The length of the rockwool strip: 1.8m~2.4m

15)The tensile strength of rockwool: ≥7.5Kpa

16)The compressive strength of rockwool: ≥40Kpa

17)Hydrophobic of rockwool: ≥98%

18)Shot content of rockwool: ≤10% Grain size>0.25mm

19)The distance from glue spray point to double belt conveyor entrance: 7m

20)The efficient length of double belt conveyor:17.8m, different glue need different gelation time.( the costomer has to prepare different glue or choose three compontent glue spray equipment)

21)Environment temperature: 10-30℃

In 2011, Weihua supplied whole continuous PU sandwich panel production line to Vietnam EVERRICH company.

Products

- Continuous Sandwich Panel Production Line

- Discontinuous Sandwich Panel Production Iine

-

Roll Forming Machine

- Roof & Wall & Door Sheet Roll Forming Machine

- Deck Floor Roll Forming Machine

- C & Z Purlin Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Downpipe Roll Forming Machine

- Box Beam Roll Forming Machine

- Folding, Shearing & Bending Machines

- Steel Springboard Roll Forming Machine

- Steel Sheet Pile Roll Forming Machine

- No-girder And Columniation Curve Roll Forming Machine

- Slitting & Cut to length line

- PU Raw Material

TOP