The function of rock wool slitting machine is to cut the rock wool block into corresponding width to meet the dimension of the final composite panel. In addition, it lays the foundation for the turning over and interface arrangement.

Through conveying roller and positional guiding, the rock wool enters into the slitting machine. The slitting blade is designed with high-precision. The cutter is manufactured according to different thickness, that is to say, each thickness is matched with one set of cutter. When change different standard, hydraulic cylinder will push the cutter out and guide rail conveys the cutter. The position of cutter is locked by locating pin to materialize shock-proof and high precision cutting. It lays the foundation for the high-quality panels as the width of rock wool is consistent.

2)Rotate speed:2900

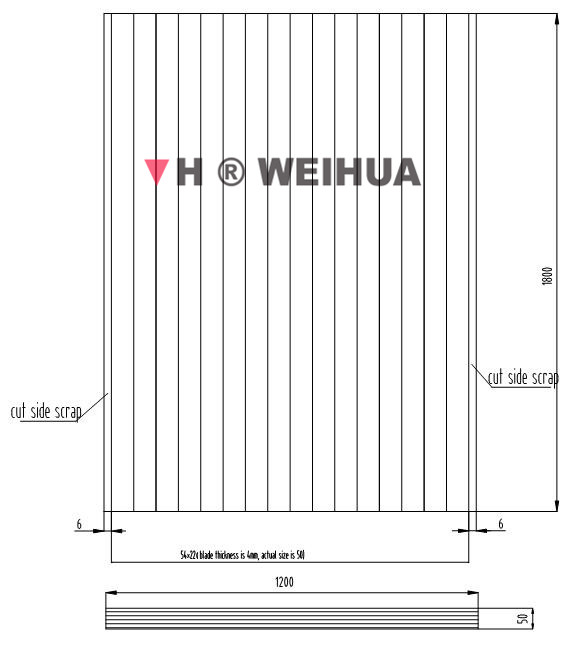

3)Diameter of cutting blade: 355mm, the specification of the blade: 355*3.3*2.2*120T

4)Quantity: 1 set foundation

5)Change way: change the blade shaft assembly, keep the foundation same.

6)Cutting linear speed: 37m/s

7)Diameter of positional cylinder: 63mm

8)Cutting press roller motor power: 0.75Kw

9)Motor power of transverse roller path before cutting: 0.75KW

10)Motor power of transverse roller path after cutting: 0.75KW

11)Output roller path speed: 18m/min

12)Nip feeding speed: 18m/min

13)Precision of the main shaft: 0.05mm

14)Roller diameter: 70mm

15)Cutting tolerance: ±0.15mm

- Continuous Sandwich Panel Production Line

- Discontinuous Sandwich Panel Production Iine

-

Roll Forming Machine

- Roof & Wall & Door Sheet Roll Forming Machine

- Deck Floor Roll Forming Machine

- C & Z Purlin Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Downpipe Roll Forming Machine

- Box Beam Roll Forming Machine

- Folding, Shearing & Bending Machines

- Steel Springboard Roll Forming Machine

- Steel Sheet Pile Roll Forming Machine

- No-girder And Columniation Curve Roll Forming Machine

- Slitting & Cut to length line

- PU Raw Material