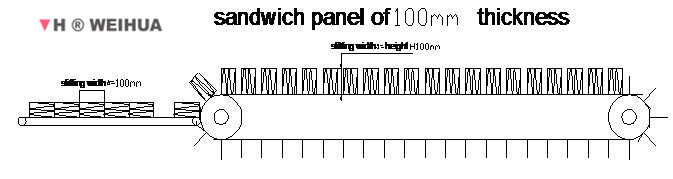

Rock Wool Strips Arrangement And Conveying

3

Share

DESCRIPTION

TECHNICAL PARAMETER

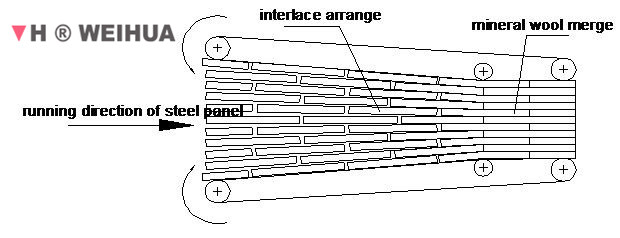

Mineral wool interlace arrange: make the wool strips interlace arrange and disperse the strips’ joints, avoid the gathering of joints and become faultage.

After turning , the rock wool enter into the conveying roller, interlace arrangement before enter the conveying belt, and tightened by the side belts to achieve the best bonding effect with steel plates. This structure can adopt irregular rockwool, those broken rockwool can also used durling production.

1)Arrange conveyor belt motor power: 2.2KW

2)Tightening belt conveyor motor power: 0.75KW

3)Conveyor belt: side active belt

FLOW CHART

2)Tightening belt conveyor motor power: 0.75KW

3)Conveyor belt: side active belt

Products

- Continuous Sandwich Panel Production Line

- Discontinuous Sandwich Panel Production Iine

-

Roll Forming Machine

- Roof & Wall & Door Sheet Roll Forming Machine

- Deck Floor Roll Forming Machine

- C & Z Purlin Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Downpipe Roll Forming Machine

- Box Beam Roll Forming Machine

- Folding, Shearing & Bending Machines

- Steel Springboard Roll Forming Machine

- Steel Sheet Pile Roll Forming Machine

- No-girder And Columniation Curve Roll Forming Machine

- Slitting & Cut to length line

- PU Raw Material

TOP