Main components of the line:

| NO. | name | quantity |

| Main roll former |

|

|

| 1 | Un-coiler (2 tons ) MANUAL | 2 |

| 2 | Main roll former | 2 |

| 3 | Saw cutter | 2 |

| 4 | PLC control cabinet | 2 |

| 5 | Output table with rollers(6 meters) | 2 |

Main parameter

1. Running material: Aluminum & Pre-painted Steel

2. Forming speed:6-15m/min

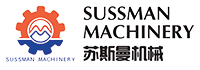

3. Forming steps: 16(as per drawing A) Forming steps: 8(as per drawing B)

4. Thickness: 0.8mm-1mm

5.Roller material: GCr15、 HRC 60.Quchend; roller diameter φ120

6. Material of shaft: #45 steel, China standard

7. Drive system: chains Transmission system,

8. Main Motor Power: 5.5 KW

9. Cutting system: Flying saw cutting (3KW), cut off after forming.

10. PLC Control system: TOUCH SCREEN: DELTA PLC: DELTA INVERTER: DELTA ENCODER: OMRON Low components of electricity: Schneider Germany

11. Rack row of work place: Steel rack of 446X199H; Detachable wall plate type row of work place

12. Un-coiler: manual un-coiler: 2 tons capacity.

13. Drawings of profile

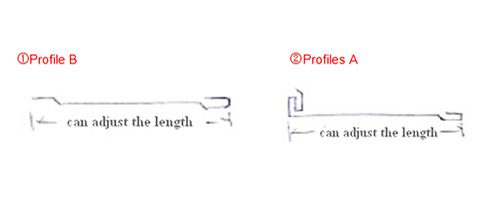

14. Dimension of Profile A: 6500*900*900MM Weight: 4Tons Dimension of Profile B: 3000*900*900MM Weight: 2.5Tons

15. The picture of profiles:

16. Main consist of the machine

Un-coiler ----- Feeding device ----- PLC control -----Roll forming ----- Pneumatic flying saw device--- Run out table

The shutter box is made by the aluminium, it is light, rust proofing, and automatically controlled by the motor.

-

Roll Forming Machine

- Drywall Stud track Roll Forming Machine

- Cable Tray Roll Forming Machine

- CZ Purlin Roll Forming Machine

-

Roller Shutter Door Machine

- Awning Tube Roll Forming Machine

- Windows Shutters Insulated Slat Machine

- Shutter Bottom Roll Forming Machine

- Curtain Rail Roll Forming Machine

- Metal Rolling Shutter Door Machine

- Double layer Insulated Shutters Door Forming Machine

- Embossing Machine

- J Track Roll Forming Machine

- L Profile Forming Machine

- Octagonal Pipe Machine

- Sectional Doors Panel Production Line

- Shutters Box Series Forming Machines

- Track Rail Automatic Bending Machine

- Track Rail Forming Machine

- U Channel Roll Forming Machines

- V Strut Forming Machine

- Windows & Doors Foam Insulated Shutters Slat Machine

- Guide Rail Roll Forming Machine

- Strut Roll Forming Machine

- Roof Panel Roll Forming Machine

- Racking Shelf Roll Forming Machine

- Deck Floor Roll Forming Machine

- Fire Damper Roll Forming

- Guard Railway Roll Forming Machine

- Gutter Roll Forming Machine

- Down Spout Roll Forming Machine

- Door Frame Roll Forming Machine

- Vineyard Post Roll Forming Machine

- Fence Post Roll Forming Machine

- Round Pipe Roll Forming Machine

- VIGACERO Ceiling Rail Roll Forming Machine

- Weld Tube Mill

- Weld Round Pipe Machine

- Decorative PU sandwich wall panel

- Slitting Machine

- Auxiliary Machine

- PU Sandwich Panel Line