Working principle:

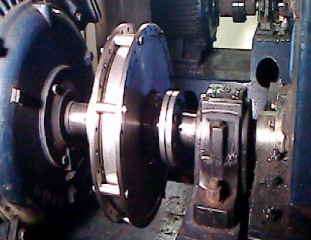

Standard Type Permanent Magnet Eddy Current Transmission mainly include the copper rotor,permanent magnet rotor. Generally copper rotor (Steel rotor with copper ring) connect with motor shaft,permanent magnet rotor (aluminum rotor with permanent magnets) connect with load shaft. There is only a air-gap between copper rotor and permanent magnet rotor without mechanical connection for transmission the torque.

Technical advantage:

Few day-maintenance,low operation cost, almost maintenance-free products

Accept misalignment, the error of centration 5mm (max), angular error 2.5 (max) 。

With overload protection, increase overall system reliability, eliminate the damage of system for overload

Improve the motor starting capability and come true the motor soft start / stop. And, reduce shock and

vibration, coordinate between multi-machine-driven load distribution.

Extend the life of the transmission system components.

Simple structure, small size, easy to install, adapt to work in harsh conditions.

Allowed adjusted the air-gap to achieve the required torque transmission and speed delivery requirements.

Supply a variety of special shaft or installation size.