Stud Track Roll Forming Machine

Product Details

Spefication

Application

| Items | Specifications |

| Material Thickness | 0.27-0.6 mm galvanized steel |

| Weight | 3 ton manual |

| Rolling Speed | 0-15m/min |

| Embossing | At sides |

| Roller Stations | About 13 stations forming |

| Roller Material | Cr40 Steel with quenching |

| Shaft Material | 45# Steel Diameter 60mm shaft |

| Maim Motor Power | 7.5 kw |

| Hydraulic cutting Power | 4 kw |

| Material Of Cutting | CR12 with quench treatment |

| Hardness | HRC58-62 |

| Tolerance | +-1.5mm |

| Cutting blade | 1 set of cutting blade |

| Electric Source | 220V, 60HZ,3 phase |

| Control System | PLC Japanese Panasonic and Yaskawa Brand |

| Weight | About 3 tons |

| Way Of Drive | 1 inch single chain |

| Size of machine | Length 6500mm* Width 600mm* Height 800m |

Application

Steel stud is very popular in the building materials.

Feature

This machine is fully automatic and high speed producing continuously, one set of forming rollers can produce various sizes of Stud and Runner just by simply and easily changing the spacers, this enables the production of different sizes products on the same rollers.

This machine is also can be designed for in line punching, punching and cutting in one time. Main motor use servo motor with frequency converter, quick or slow speed can be adjusted freely. After roll forming, automatic in line punching and cutting continuously. Cutting length: from 3 meter to 6 meter, etc. length tolerance: within ±1mm. Automatic products piling table is special designed for high speed production capacity and reduce the production cost, create more profit for the customers.

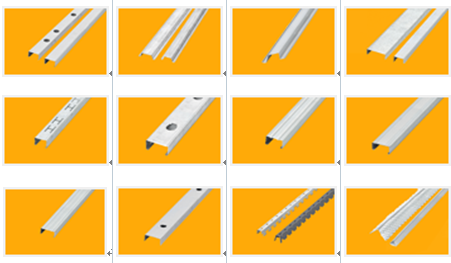

Products

TOP