More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut to length line, etc.

Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer.

We always keep strong faith in “Thinking for what customer think”.

Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales”

Our TZG series High Precision Welded Pipe&Tube Line with the latest technology,meet high efficiency output ,easily operated and stable running performance,also the complete tube mill line meet a high level automation.

This high precision tube mill series with excellent design, selected high precision durable roller under strictly quenching , high performance cutting saw, complete machine body with heat treatment, accurate fabrication, precise assembly.

The machine performance has reached the international ERW welded tube standard. This tube mill series outer diameter range can be from Φ13mm to Φ 100mm and wall thickness of 0.8~4.5mm,all these size tubes are produced with large output, best quality and high precision.Our customized machines are also can be used for different processed material and meet nearly all applications.

Specification of High precision series tube mill line

|

Model |

Tube O.D.(mm) |

Wall Thickness(mm) |

Speed(m/min) |

H.F. power(Kw) |

Main motor(Kw) |

|

TZG-45 |

φ13-50.8 |

0.8-2.0 |

20-70 |

100 |

75 |

|

TZG-50 |

φ15-63.5 |

0.8-2.5 |

20-70 |

150 |

90 |

|

TZG-60 |

φ16-63 |

1.0-3.0 |

20-60 |

200 |

132 |

|

TZG-76 |

φ25-80 |

1.2-4.0 |

15-60 |

300 |

160 |

|

TZG-90 |

φ32-100 |

1.5-4.5 |

15-50 |

350 |

180 |

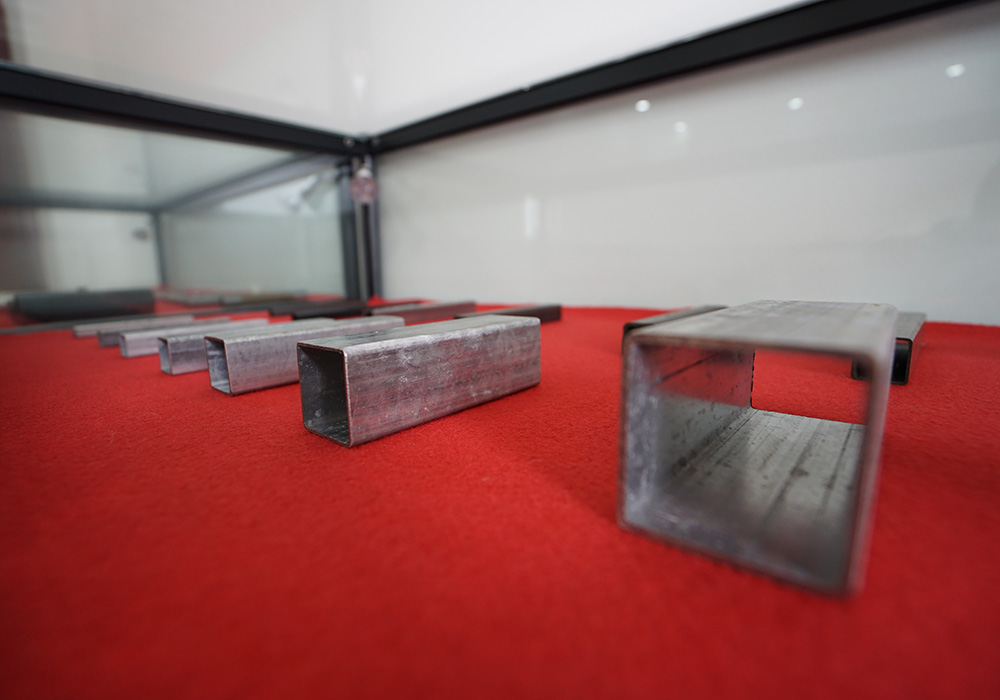

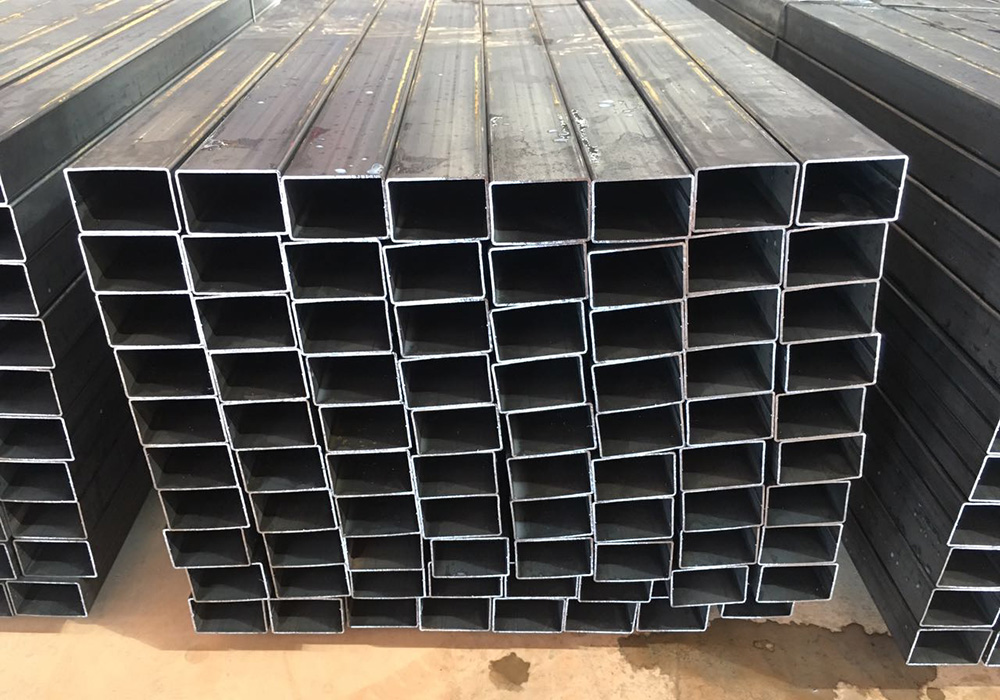

Finished Products

|

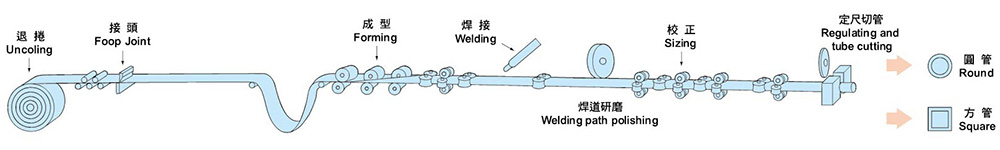

Product (steel tube) Process Flow: |

|

|

Raw material (steel coil) → uncoiling → shearing and end welding → material accumulating → non-power leveling → mill-forming → high-frequency welding → removing burrs outside of weld seam → cooling → sizing → roughly straightening → fixed length cutting → finishing tube |

|

High Frequency Resistance Welding,HFRW

HFRW can generate resistance heat through connecting welding parts by 10-500KHz high frequency current that heat up the outer surface of welding parts to become fusion and plastic state.Meanwhile two side of metal joint can be fused together by HFRW welding that is Solid State Resistance Welding technology.

High Frequency Resistance welding(HFRW) is invented in the earlier year 1950 later it rapidly used for industrial production.Nowadays HFRW is mainly used for mechnical and pipe &tube and profile under high-level-automation field.

The material of welded parts can be steel or non-ferrous metal, tube diameter range from 6-1420mm,wall thickness from 0.15 to 20mm.Normally small dia tube adopt longitudinal welding seam.Large pipe mostly adopt spiral welding seam.

Advantage of HF welding.

High welding speed

As the current can be highly concentrated in the welding area, heating speed is extremely fast, the general high frequency welding speed up to 150-200m/min.

Small heat affected area

Because of the high welding speed and the self-cooling effect of the weldment, the heat affected area of the high frequency welding is small and hardly oxidized, so that the welding seam get good structure and performance.

No need clean before welding

As high-frequency current has very high voltage,it can breakover the weld surface oxide film, also through the flash process, extrusion,it can effectively remove the oxide of connector and other impurities. Inert gas is only used for protect metal welding such as titanium,etc which has very fast reaction with oxygen and nitrogen, only need to use inert gas for protection

1.Uncoiler

1.Uncoiler 2.Shear and butt weld

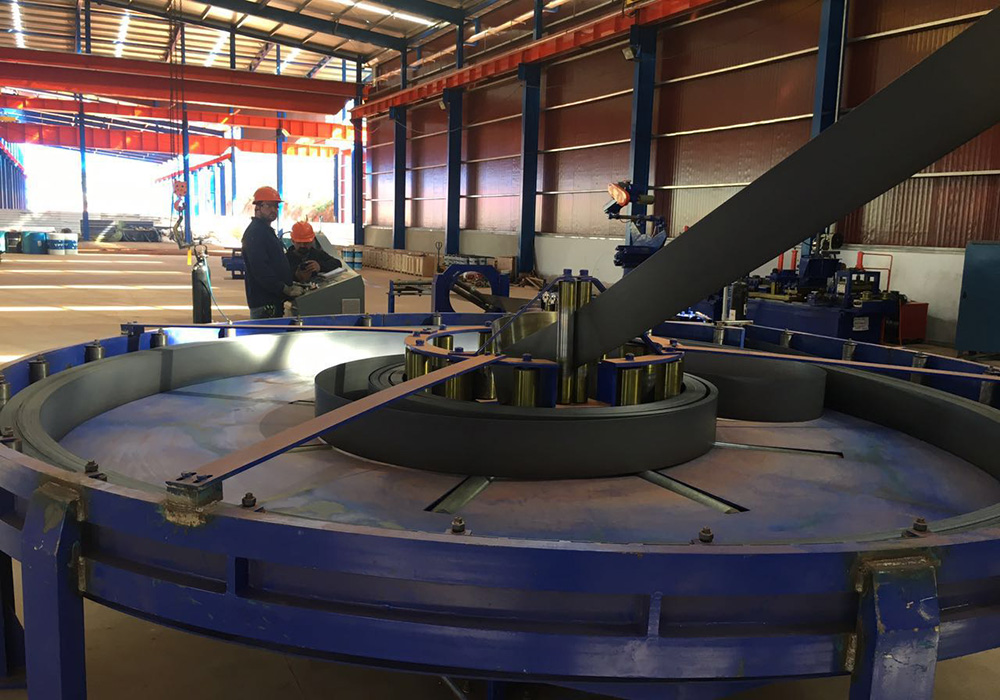

2.Shear and butt weld 3.Horziontal accumlator

3.Horziontal accumlator 4.Forming

4.Forming  5.HF welding

5.HF welding  6.Turkey straightener head

6.Turkey straightener head 7.Cut off saw

7.Cut off saw 8.Run out table

8.Run out table 9.Transmission part

9.Transmission part