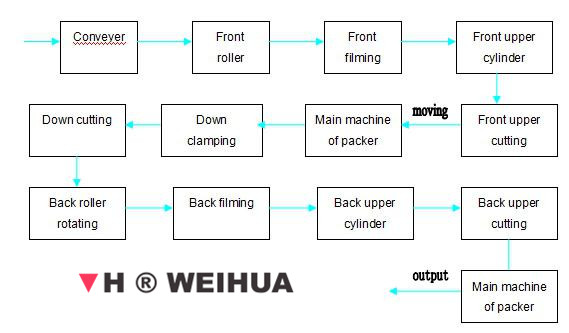

Wrapping machine is the equipment that used for plastic packing for the panels after neatly stacking. Our company’s wrapping machine has the functions of two ends of panel packing, auto block putting and packing according the panel length. It can packing the six sides of sandwich panels and blocks at one time, and has good tightness and automaticity.

The wrapping machine can satisfy the functions of two ends of panel packing, auto block putting and packing according the panel length. It includes the connecting rollers with the fast rollers. All the technical parameters and size arrangement provided by the suppler according to the production drawing. There are two parts of the back rollers and each part is 10m. One part is thick rollers which in a dense order and the roller of which is 60mm to guarantee the block without falling.

1)Roller path before wrapping machine working speed: 7m/min

2)Space for the roller path before wrapping machine: 7.2m*1.5m*0.5m

3)Foam pad size: 1000mm*300mm*100mm;

4)Max wrapping height: 800mm—1300mm;

5)Wrapping length:>2m;

6)Convolve speed: 22r/min

7)Convolve film type: φ76*φ26*520,PE

8)Packing machine size : 6.3m*3.2m*3.8m

9)The roller path is driven roller path, sandwich panel dimension: 300-1300mm height,400-1200mm width, 2000-15000mm long. 10)Transmission speed: 0-6m/min

11)Reducer Type:C71-4.5-Y-4-B3

12)Motor Power: 4kW Frequency Motor

13)Control : PLC, linkage

14)Filming : top film 1000mm(2 pcs),

15)Push pad: Air cylinder QSN232×200BCB, line guide way:BRH25B×350;

16)Top cutting: Air cylinder QGWN250×1500BSD;

17)Bottom cutting: Air cylinder QGWN250×1500BSD;

- Continuous Sandwich Panel Production Line

- Discontinuous Sandwich Panel Production Iine

-

Roll Forming Machine

- Roof & Wall & Door Sheet Roll Forming Machine

- Deck Floor Roll Forming Machine

- C & Z Purlin Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Downpipe Roll Forming Machine

- Box Beam Roll Forming Machine

- Folding, Shearing & Bending Machines

- Steel Springboard Roll Forming Machine

- Steel Sheet Pile Roll Forming Machine

- No-girder And Columniation Curve Roll Forming Machine

- Slitting & Cut to length line

- PU Raw Material