XGF Washing, Filling- Sealing Production Line

Description

It is Applicable to the washing, filling and sealing production for soft or hard PP Plastic bottle IV-solution.

Characteristics:

1.Washing,filling and sealing are closely connected , thus it occupies less space, it has simple installation, easy operation and high automation.

2. The line adopts PLC programmable controller, which is powerful and complete in intelligence control.

3. It adopts unique CIP and SIP, which is time-saving for washing and effective in sterilization. Time, pressure and temperature of CIP, SIP can be easily adjusted on the touch screen by operators accor ding to products needs.

Main technical parameters

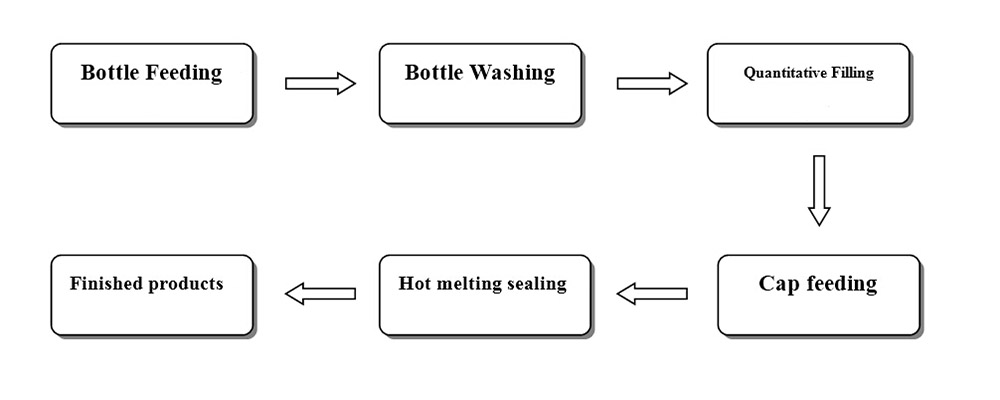

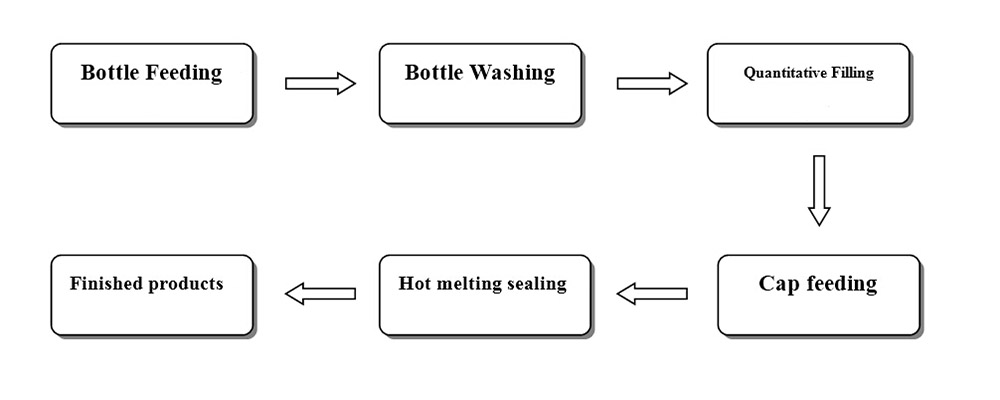

Process

Characteristics:

1.Washing,filling and sealing are closely connected , thus it occupies less space, it has simple installation, easy operation and high automation.

2. The line adopts PLC programmable controller, which is powerful and complete in intelligence control.

3. It adopts unique CIP and SIP, which is time-saving for washing and effective in sterilization. Time, pressure and temperature of CIP, SIP can be easily adjusted on the touch screen by operators accor ding to products needs.

Main technical parameters

| Production Ability | 2000 ~20000 bottles/hour |

| Specification | 50~500ml circular or heteromorphy plastic bottle |

| Bottle Washing | ionic air blowing |

| Quantity Of Washing | 20 ~60 |

| Quantity Of Filling | 18 ~48 |

| Quantity Of Sealing | 20 ~60 |

| Main Filling Medium | Liquor such as large capacity |

| Filling Error | ± 1.5 % |

| Liquor Temperature and Pressure | 40 ~55 ℃ 0.6 ~2kg/cm² |

| CIP/SIP | 125 -30min |

| Gas-Consumption(dust-proof air) | pressure 0.6 ~0.8Mpa 180(120)m³/ h |

| Cooling Water | 250L / h,15~20 ℃ |

| Noise max. | 75dB |

| Electric Capacity | 18~35KW |

Process

Products

- Non-PVC Soft Bag IV Solution Production Line

- PP Bottle IV Solution Production Line

- Vacuum Blood Collection Tube Production Line

- Capsule filling machine production line

- Tablet press production line

-

ointment production line

- vacuum emulsifying mixer

- laboratory vacuum emulsifying mixer

- tube filling and sealing machine

- semi-automatic tube filling and sealing machine

- metal tube filling and sealing machine

- wltrasonic tube sealing machine

- automatic wltrasonic tube filling sealing machine

- semi-automatic cartoning machine

- sellophane overwrapping machine

TOP