High rigidity separated structure casting frame, with guide pillar / sleeve unit.

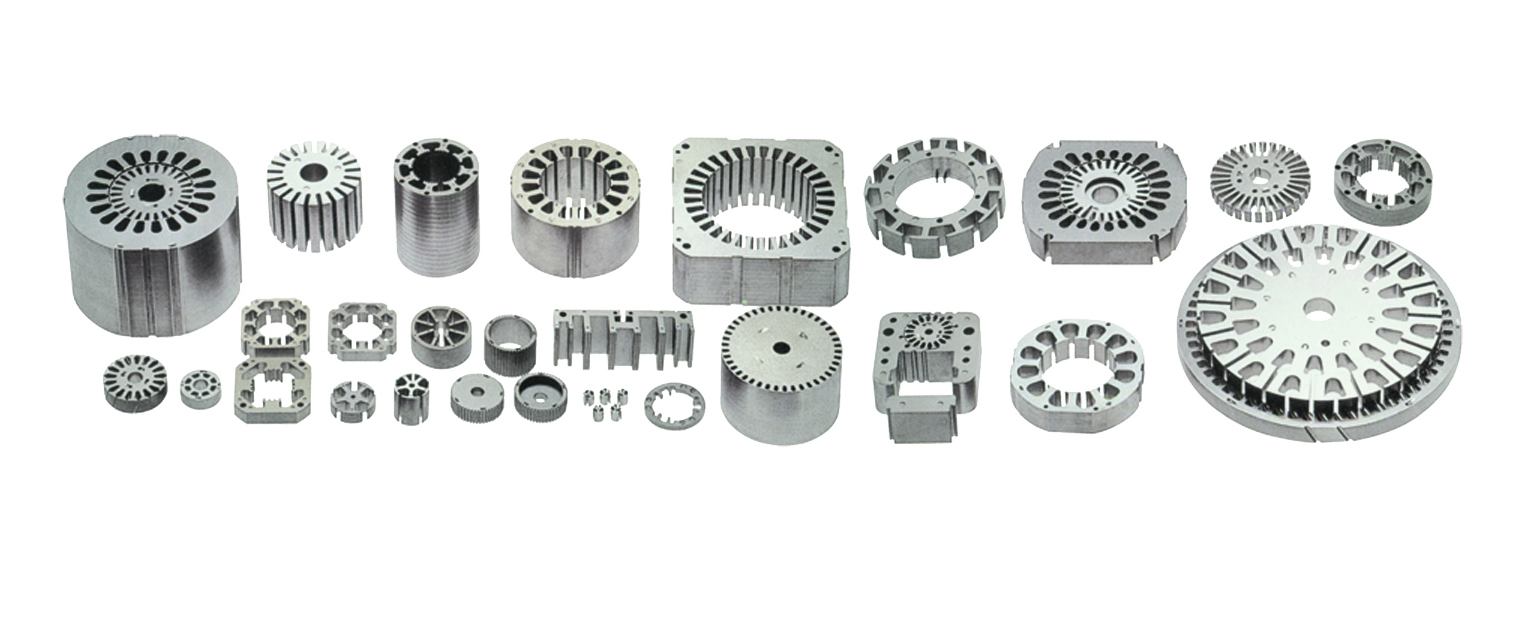

Suitable for Automatic high speed stamping of motor lamination.

J76 series straight side high-speed Two-point Press line is Separated-structure and high-rigidity cast iron frame, base and crossbeam are tightened by four tensile screw rods, with high rigidity and less deformation; Automatic temperature control system and using the thermal compensation technology to control the position of bottom dead center in high precision; Four point crankshaft supporting structure, enhancing the strength of crankshafts, less deformation, high rigidity and strong load deviation resistant capability. Gas chamber balance device, to balance the slide and the weight of upper die, ensuring the balance of the press in running; Imported pneumatic combination friction clutch-brake, with low noise, long service life, large clutch torque and small braking angle, to ensure reliable safety and flexible action The machine has dynamic balancing system, reducing the noise from vibration, extending the service life of the dies and improving working environment; Suitable for Automatic high speed stamping of motor lamination.

Main Structure Features

- Separated structure and high rigidity cast-iron frame

- High strength eccentric alloyed steel crankshaft

- Imported bearings and four-point crank supporting structure(80-300T)

- Slide is guided by liner clearance-free ball bearing plunger bushes

- Low vibration and low noise

- Big torque, low inertia, pneumatic clutch-brake unit

- Hydraulic locking device for adjustment rods , ensuring the precision of bottom dead center

- Forced lubrication system, automatic temperature control system and using the thermal compensation technology to control the position of bottom dead center in high precision

- Programmable cam controller

- Touch screen

| Item | J76-80 | J76-125E | J76-200E | J76-300E | J76-550 | J76-750 | ||

|---|---|---|---|---|---|---|---|---|

| Nominal pressure | kN | 800 | 1250 | 2000 | 3000 | 5500 | 7500 | |

| Nominal pressure stroke | mm | 2 | 3 | 3 | 3 | 1.6 | 1.6 | |

| Stroke of slide | mm | 30 | 30 | 30 | 30 | 40 | 50 | |

| Stroke | spm | 200-600 | 160-500 | 160-450 | 160-400 | 80-230 | 80-180 | |

| Max. die set height | mm | 380 | 400 | 420 | 450 | 550 | 650 | |

| Die height Adjustment | mm | 50 | 50 | 50 | 50 | 100 | 100 | |

| Distance between uprights | L-R | mm | 1140 | 1340 | 1740 | 2150 | 3080 | 3800 |

| F-B | mm | 320 | 400 | 400 | 470 | 1050 | 1320 | |

| Bottom size of slide | L-R | mm | 1100 | 1300 | 1700 | 2100 | 3050 | 3650 |

| F-B | mm | 500 | 600 | 650 | 750 | 1400 | 1700 | |

| Size of table | L-R | mm | 1100 | 1300 | 1700 | 2100 | 3050 | 3650 |

| F-B | mm | 750 | 850 | 950 | 1000 | 1500 | 1700 | |

| Suitable material width | mm | 100 | 150 | 250 | 350 | 550 | 650 | |

| Main Motor power | kW | 22 | 22 | 37 | 45 | 75 | 90 | |

| Overall dimension | L-R | mm | 2220 | 2620 | 3090 | 3600 | 6100 | 6800 |

| F-B | mm | 1500 | 1560 | 1900 | 2000 | 3150 | 3000 | |

| Height | mm | 3425 | 3750 | 4100 | 4920 | 7785 | 8500 | |

| Total weight | kg | 18000 | 24000 | 36000 | 60000 | 166000 | 210000 | |