YKC Series H-type Frame High-speed Fin Press Lines

1449

Share

Features

YKC series H-frame fins press line for the punching of air conditioner fins is specially intended for meeting the requirements of air conditioner fins. Equipped with optional die change system photoelectric protector. Buttons, indicators, AC contactors, air circuit breakers and other controlling devices are imported from internatioanal brand. Controled by PLC with international brand. The line is mainly consists of uncoiler, oil tank, fin press suction unit, stacker and relevant electrical control system. Imported The PLC, counter and contact point free cam controller are all imported,which meet the requirements of counting the fins cut collected as well as the function of progress change.

Parameter

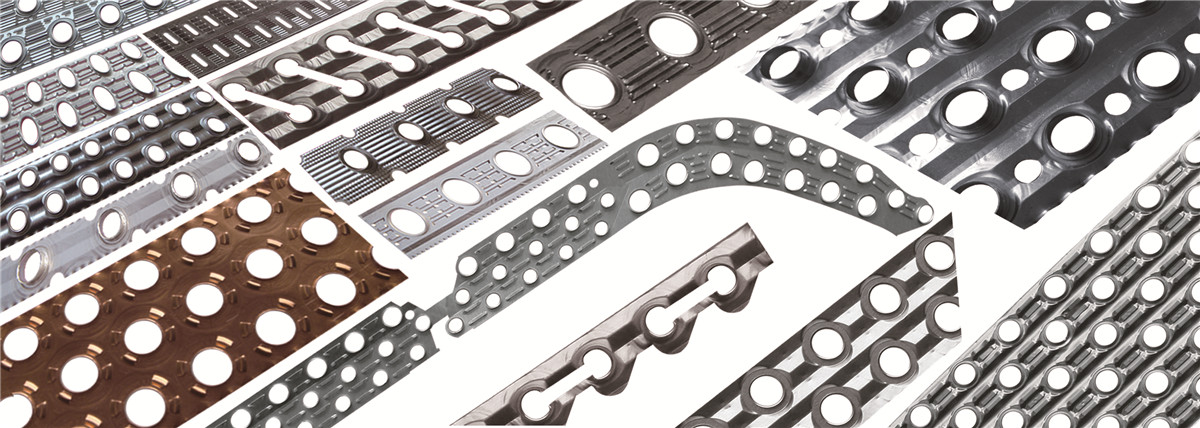

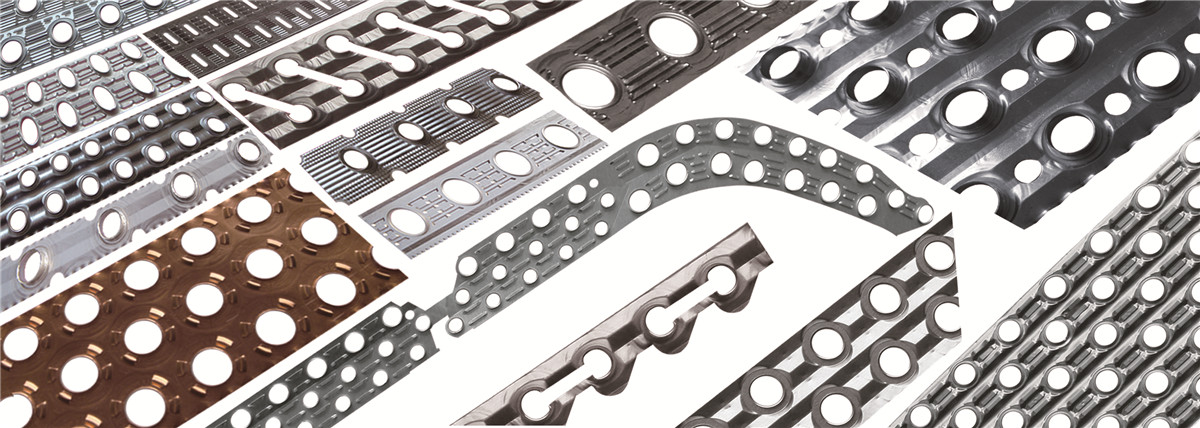

Product Sample

Video

Video

Used for Automatic high efficiency production of aluminum fins.

Servo feeder device, lifting stacker unit, scraps blowing unit can be provided as optional accessories.

YKC series H-frame fins press line for the punching of air conditioner fins is specially intended for meeting the requirements of air conditioner fins. Equipped with optional die change system photoelectric protector. Buttons, indicators, AC contactors, air circuit breakers and other controlling devices are imported from internatioanal brand. Controled by PLC with international brand. The line is mainly consists of uncoiler, oil tank, fin press suction unit, stacker and relevant electrical control system. Imported The PLC, counter and contact point free cam controller are all imported,which meet the requirements of counting the fins cut collected as well as the function of progress change.

Main Structure Features

- Composition: Uncoiler, oil tank, air feeder, fin press, suction unit and stacker, electric control system, air system, air system,hydraulic system.

- The slide of power press has hydro-lifting function which will be convenient for dies installation / commissioning.

- Power press speed & vacuum stacker is controlled by converter.

- Collector has protecting system for fault operation no material warning, no oil warning.

- Hydraulic overload protection for main machine.

- Equipped with hydraulic rapid-dies changing device, making dies change more quickly and convenient.

- Machine-human interface and PLC electrical control system ensuring the reliable operation of the automatic punching.

| Item | YKC-18-45 | YKC-24-63 | YKC-24A-63 | YKC-36-80 | YKC-36A-100 | YKC-48A-125 | YKC-48H-125 | YKC-160 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal pressure | kN | 450 | 630 | 630 | 800 | 1000 | 1250 | 1250 | 1600 | |||||||

| Stroke of slide | mm | 40 | 60 | 50 | 40 | 60 | 50 | 40 | 40 | 40 | 40 | 30 | 80 | 70 | 60 | |

| Stroke | spm | 150-300 | 150-230 | 150-260 | 150-300 | 150-230 | 150-260 | 150-300 | 150-300 | 150-300 | 150-300 | 150-400 | 150-200 | 150-220 | 150-230 | |

| Die height | mm | 260-310 | 260-310 | 260-310 | 280-330 | 280-330 | 280-330 | 280-330 | 280-330 | |||||||

| Slide lifting height | mm | 80 | 80 | 80 | 100 | 120 | 130 | 130 | 130 | |||||||

| Bottom size of slide (LxW) | mm | 720x740 | 800x890 | 1100x890 | 1055x1190 | 1300x1190 | 1300x1350 | 1300x1350 | 1300x1190 | |||||||

| Size of table (LxWxThickness) | mm | 1300x770 | 1350x900 | 1600x900 | 1600x1200 | 1800x1200 | 2000x1360 | 2000x1360 | 2000x1200 | |||||||

| Width of material | mm | 400 | 550 | 550 | 820 | 820 | 1080 | 1080 | 500 | |||||||

| Sucking length | mm | 1000 | 1000 | 1000 | 900 | 900 | 900 | 900 | 900 | |||||||

| Collectiong height of material | mm | Normal 720mm, Lift 900mm | ||||||||||||||

| Inner diameter of material rolling | mm | Φ150 | Φ150 | Φ150 | Φ150 | Φ150 | Φ150 | Φ150 | Φ480-550 | |||||||

| Outer diameter of material rolling | mm | Φ1000 | Φ1000 | Φ1000 | Φ1200 | Φ1200 | Φ1200 | Φ1200 | Φ1200 | |||||||

| Main motor power | kW | 7.5 | 7.5 | 11 | 15 | 18.5 | 22 | 22 | 22 | |||||||

| Overal dimension(LxWxH) | mm | 7500x3500x3200 | 7500x3500x3500 | 10000x4000x3200 | 10000x4000x3500 | 10000x4000x3500 | 10000x4500x3800 | 10000x4500x3800 | 10000x4000x3500 | |||||||

| Total weight(approx.) | kg | 9000 | 12000 | 14000 | 18000 | 20000 | 26000 | 26000 | 22000 | |||||||

| Remark |

|

Single crank structure, and the crank is installed from front to rear | Double cranks structure, and the cranks are installed from front to rear | |||||||||||||

| Die change deivce/initial feeding device |

|

Optional | Standard | |||||||||||||

| Curtain sensor |

|

Optional | Standard | |||||||||||||

TOP