Sheet Metal Fabrication

124

Share

Machinery

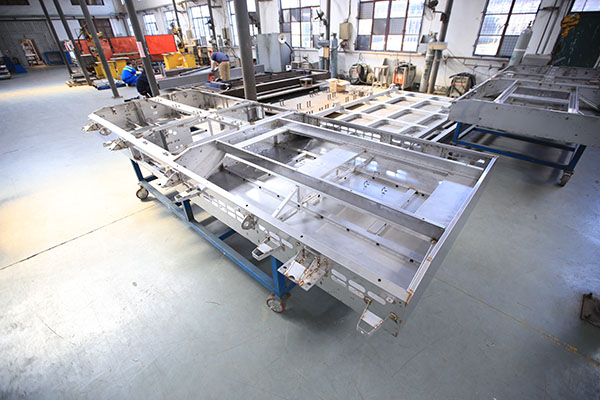

Sheet Metal Fabrication: Manufacture the products based on design & concept by processes as cutting, bending, forming, welding that made from steel, stainless steel, aluminum at 0.5-20mm thick (gauge). Our sheet metal workshop is equipped with 2 laser cutting machines, 2 CNC punches, 10 CNC bending machines, and 15 welding machines as well as tools for other general fabrications as taping, drilling, nut inserting etc.

Cutting: A way of removing material from sheet, mostly by

• Laser Cutting • CNC Punch • Plasma Cutting • Waterjet Cutting • Shear Bending & Forming: A way of changing the sheet to reach the desired shape, mostly by

• CNC Bending • Rolling

Welding: A way of jointing 2 or more parts including

• Tig Welding • Mig Welding • Spot Welding

Extra Functional or Visual Furnish:

• Taping: Drill threads on the material

• Nut Insertion: Press or fit PEM nuts on the material.

• Powder coating, zinc plating, hot dipped galvanization, painting etc.

Product Photos

Workshop Photos

Cutting: A way of removing material from sheet, mostly by

• Laser Cutting • CNC Punch • Plasma Cutting • Waterjet Cutting • Shear Bending & Forming: A way of changing the sheet to reach the desired shape, mostly by

• CNC Bending • Rolling

Welding: A way of jointing 2 or more parts including

• Tig Welding • Mig Welding • Spot Welding

Extra Functional or Visual Furnish:

• Taping: Drill threads on the material

• Nut Insertion: Press or fit PEM nuts on the material.

• Powder coating, zinc plating, hot dipped galvanization, painting etc.

TOP