Steel Cut Wire Shot

26

Share

Features

Application

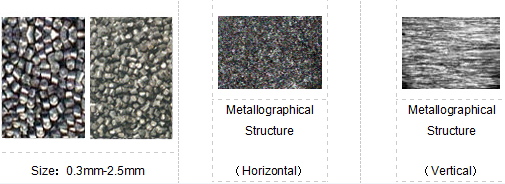

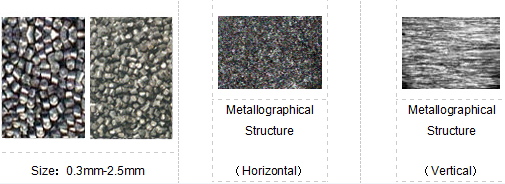

Steel cut wire shot is made with the process of drawing, cutting and conditioned etc. rigidly according to the standards of VDFI 8001/1994 and USA SAE2431. The particles of shot are uniformly size with the respective hardness of HV400-500, HV500-555, HV555-605, HV610-670, HV670-740 and more. And the granularity is distributed from 0.2mm to 3.0mm. The shapes of them are columnar and spherical with conditioned G1, G2, G3. Besides, their useful durability are ranged from 3500cycles to 9600 cycles.

Type

Apply to equipment

Steel Cut wire Shots are typically used for the blasting machine with drum type, chain type, lifting hook type, crawler type, pass type, rotating table type, accumulation type, marching type and car type. Also can used for shot blast equipments, pretreatment of the production line, and sand blasting room.

Package

Our company can carry out woven bag packaging, ton bag packaging, wood tray packaging, plastic packing packaging and the like according to customer requirements.

Advantage of Steel cut wire shot

Compared with steel grit, you can get 30% reduction on cost. According to our experience, steel cut wire shot will turn into round shot after long-time use.bright appearance, no dust and long durability is the advantage of our steel cut wire shot. Shanghai Bosun Abrasive company is the earliest manufacturer of steel cut wire shot.

Technical Data

Type

Apply to equipment

Steel Cut wire Shots are typically used for the blasting machine with drum type, chain type, lifting hook type, crawler type, pass type, rotating table type, accumulation type, marching type and car type. Also can used for shot blast equipments, pretreatment of the production line, and sand blasting room.

Package

Our company can carry out woven bag packaging, ton bag packaging, wood tray packaging, plastic packing packaging and the like according to customer requirements.

Advantage of Steel cut wire shot

Compared with steel grit, you can get 30% reduction on cost. According to our experience, steel cut wire shot will turn into round shot after long-time use.bright appearance, no dust and long durability is the advantage of our steel cut wire shot. Shanghai Bosun Abrasive company is the earliest manufacturer of steel cut wire shot.

| Name | Steel Cutwire Shot | ||||||

|---|---|---|---|---|---|---|---|

| Chemical Composition | C | 0.45~0.75% | |||||

| Mn | 0.40~1.20% | ||||||

| Si | 0.10~0.30% | ||||||

| S | <0.04% | ||||||

| P | <0.04% | ||||||

| Hardness | 41~45 HRC(388~436HV) 51-55HRC (530-600HV) | ||||||

| Hardness Deviation | Max Deviation ±1.0HRC or ±40HV | ||||||

| Tensile Strength | 1660~2200Mpa | ||||||

| Mettallographical Stucture |

|

|

|||||

| Min Density (Can be determined by alcoholic displacement) | 7.8g/cm3 | ||||||

Applications

1. Shot pretreatment: coating pretreatment, surface preparation, pretreatment

2. Playing sand: playing sand.

3. Cleaning: shot blasting, shot blasting, casting cleaning, blast cleaning castings, forgings, shot blasting, shot blasting forging, casting sand, steel cleaning, cleaning up of steel, steel cleaning.

4. Shot: steel blasting, steel shot blasting, steel shot blasting.

5. Strengthening: shot peening, heat treatment pieces of shot peening, shot peening gear.

6. Shot: steel shot, steel sandblasting, ship blasting, steel shot, steel shot.

7. Rust: shot blasting, abrasive blasting, casting rust, rust forgings, forgings descaling steel rust, steel rust.

1. Shot pretreatment: coating pretreatment, surface preparation, pretreatment

2. Playing sand: playing sand.

3. Cleaning: shot blasting, shot blasting, casting cleaning, blast cleaning castings, forgings, shot blasting, shot blasting forging, casting sand, steel cleaning, cleaning up of steel, steel cleaning.

4. Shot: steel blasting, steel shot blasting, steel shot blasting.

5. Strengthening: shot peening, heat treatment pieces of shot peening, shot peening gear.

6. Shot: steel shot, steel sandblasting, ship blasting, steel shot, steel shot.

7. Rust: shot blasting, abrasive blasting, casting rust, rust forgings, forgings descaling steel rust, steel rust.

TOP