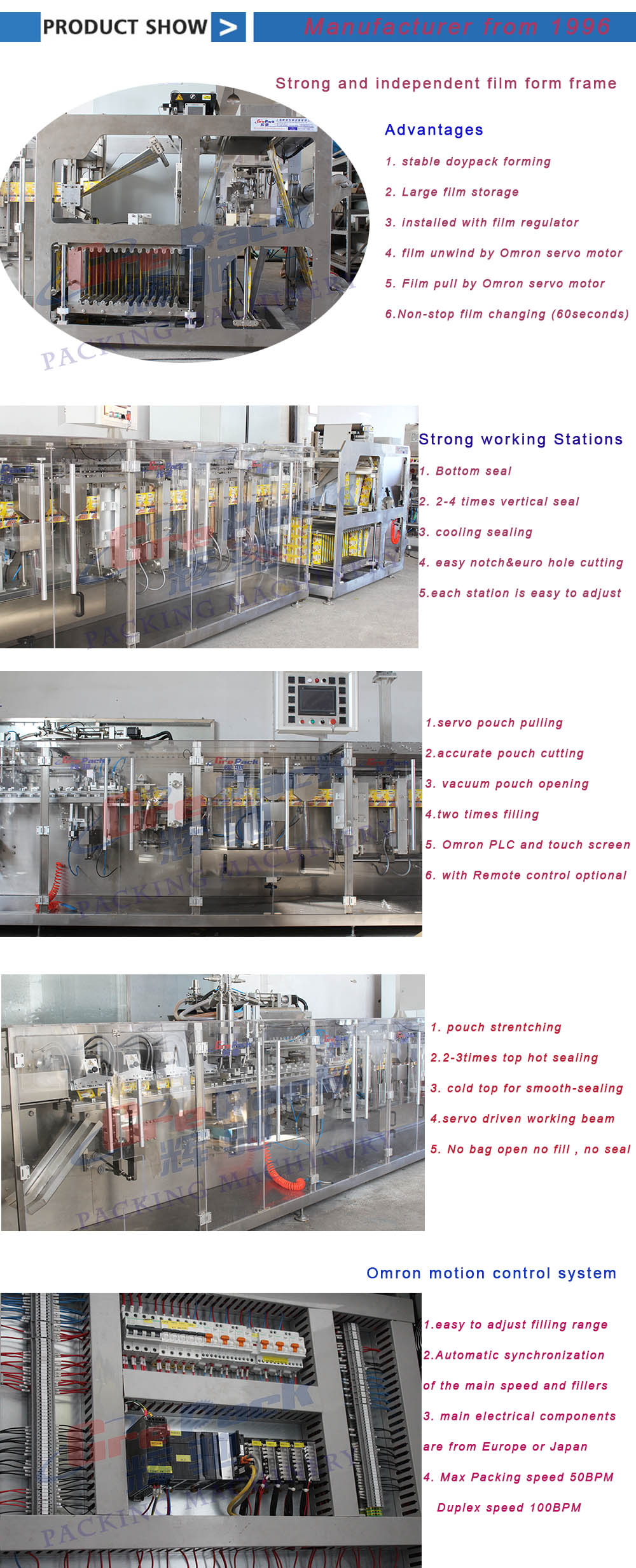

Stand up/doypack pouch form fill seal packing machine

1) PLC control , English and man-machine interface, operating easy and simple maintain .

2) Advanced photoelectric sensor tracking system and servo motor pull for precise bag width and position of film.

3) versatile machine could make doypack bag with zipper or spout , unique bag shape could be designed according to requirement .

4) Independent digital temperature controller for vertical and horizontal sealing, intuitive and accurate.

5) Easy and fast adjustment of change over, the machine has strength extensibility, could fill two or even more products into one bag by added filling device .

6) Smooth performance and low noise, perfect package appearance, Sensible safety device and no pollution during production to get Friendly working environment

|

Model |

HC-180S/240S |

|

Measuring range |

100-1000ml |

|

measuring method |

piston pump filler |

|

bag size |

length 110-250mm width90-180mm |

|

Capacity(max) |

single model : 30-50 bags/min Duplex model :100bags/min |

|

Control style |

PLC+ English touch screen |

|

Power |

8KW |

|

Power supply |

AC 380V 50Hz |

|

Air pressure |

0.6Mpa |

|

Weight |

N.W.:2150Kg |

|

Dimensions(mm) |

6900(L)×1210(W)×1500(H) |

|

Bag shape |

Stand up pouch / duplex doypack |

1) PLC control , English and man-machine interface, operating easy and simple maintain .

2) Advanced photoelectric sensor tracking system:

No Pouch, No Filling ; short film alarm and stop machine

3) UV Sterilization for Film

4) servo motor pull system for precise bag width and position of film.

5) Temperature detection : independent digital temperature controller for vertical and horizontal sealing, intuitive and accurate.

6) easy and fast adjustment of change over .

7) smooth performance and low noise, perfect package appearance with enough film storage, Sensible safety device and no pollution during production to get Friendly working environment.

Characteristics

It can be used to pack liquid product such as milk ,juice, ketchup ,paste, shampoo, detergent, softener etc. up to 1000ml

- Automatic Labeling Machine

- Automatic Filling Machine

- Form Fill Seal Pouch Packing Machine

- HFS premade pouch packing machine

- Vertical sachet packing machine

- Rotary Premade pouch packing machine

- Automatic Capping Machine

- Case & carton Erector Machine

- Case &carton Packing Machine

- Case & carton Sealing Machine

- Palletizer robot Machine

- Automatic Filling Line

- Pouch Packing line

- Other packing machine

- Selection Guide

- Turnkey Project