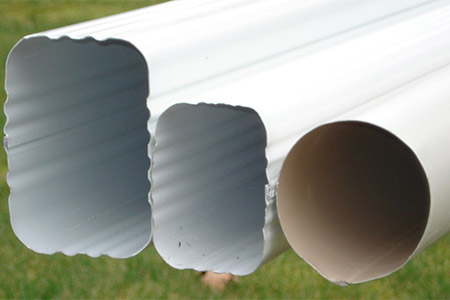

Round Pipe Roll Forming Machine

Spefication

Application

1. Machine specification: thickness 0.5-0.6mm, stainless steel 304 yield strength≤G250Mpa

2. Forming speed: 12M/min (EXCLUDING CUTTING STOP TIME)

3. Forming roller: about 24 stations

4. Main motor power: 11KW with gear box, speed adjustable by transducer

5. Roller material: 45# forged steel, surface coated with chrome

6. Main shaft material: 45# steel

7. Main axis dia.:¢70mm

8. Hydraulic cutting pressure: 10-12Mpa

9. Cutting method: hydraulic powered, cutting after roll forming.

10. Cutting blade material: Cr12 quenching treatment

11. Electrical controlling system: Whole line adopted PLC control, cut to length tolerance≤2mm

A downspout is a pipe for carrying rainwater from a rain gutter.Downspouts are usually vertical and usually extend down to ground level. The water is directed away from the building's foundation, to protect the foundations from water damage. The water is usually piped to a sewer, or let into the ground through seepage.The first ever downspout to be installed was in 1240 on the Tower of London, as it was whitewashed and the newly painted walls had to be protected from the rain. Decorative heads are sometimes added, these being low-height gargoyles.

Products

-

Roll Forming Machine

- Drywall Stud track Roll Forming Machine

- Cable Tray Roll Forming Machine

- CZ Purlin Roll Forming Machine

-

Roller Shutter Door Machine

- Awning Tube Roll Forming Machine

- Windows Shutters Insulated Slat Machine

- Shutter Bottom Roll Forming Machine

- Curtain Rail Roll Forming Machine

- Metal Rolling Shutter Door Machine

- Double layer Insulated Shutters Door Forming Machine

- Embossing Machine

- J Track Roll Forming Machine

- L Profile Forming Machine

- Octagonal Pipe Machine

- Sectional Doors Panel Production Line

- Shutters Box Series Forming Machines

- Track Rail Automatic Bending Machine

- Track Rail Forming Machine

- U Channel Roll Forming Machines

- V Strut Forming Machine

- Windows & Doors Foam Insulated Shutters Slat Machine

- Guide Rail Roll Forming Machine

- Strut Roll Forming Machine

- Roof Panel Roll Forming Machine

- Racking Shelf Roll Forming Machine

- Deck Floor Roll Forming Machine

- Fire Damper Roll Forming

- Guard Railway Roll Forming Machine

- Gutter Roll Forming Machine

- Down Spout Roll Forming Machine

- Door Frame Roll Forming Machine

- Vineyard Post Roll Forming Machine

- Fence Post Roll Forming Machine

- Round Pipe Roll Forming Machine

- VIGACERO Ceiling Rail Roll Forming Machine

- Weld Tube Mill

- Weld Round Pipe Machine

- Decorative PU sandwich wall panel

- Slitting Machine

- Auxiliary Machine

- PU Sandwich Panel Line

TOP