PUR outer sheath anti-distortion welding cable as the power control and signal transmission, suitable for installation in torsion and bending stresses at the same time the existence of a variety of welding equipment, such as welding robots and manipulators, automatic gun, auto welding production line welding robot and robot connections and assembly, also suitable for connecting a rotary-type or lift table.

Industrial Robot consists of three basic parts the body, drive system and control system.

The body includes the base and implementing agencies, including the arm, wrist and hand. Drive system includes power plant and transmission mechanism for the actuator to produce a corresponding action.

Control system is programmed in accordance with the input of the drive system and actuators sending a command signal to achieve signal control.

Robot Cable Covers: Servo motor cable, Encoder cable, Signal control cable, Data cable bus and servers.

Different from 2D drag chain cable, robot cable shows a higher performance. One hand, it requires the cable should have a high degree of anti-torsion ability to adapt equipment 3D motion. Another hand, the cable is completely exposed to the industrial field, welding sparks, cooling water, oil and other environmental factors is exist, so it should have the abilities to defend them.

Currently, the robot cable is mainly used for automobile assembly and production, food processing, paper, beverages and other automated production lines. We can provide a full range of robot cable products, including servo motor cable, encoder cable, signal control cable, data cable bus and servers, besides we can also customize products according to your requests.

Feature

• Optimized product structure, with higher flexibility, minimum bend radius up to 7.5D;

• Full range of products, include servo motor cable, encoder cable, signal control cable, data cable bus and servers;

• Safe and reliable, robotic products provided by us have received simulation application environment tests to ensure product reliability;

• Our offer cable insulation and jacketing materials used in robotics, mostly Self-developed materials have excellent performance: wear resistance, anti-torsion, chemical resistant etc.;

• UL, CSA, VDE certificates on request;

• In addition, we can also provide customized robot cable.

1. Cable flexibility, tensile wear-resistance, oil resistance, corrosion resistance, low temperature bending

2. Voltage: 300 / 500V 450 / 750V 600 / 1000V

3. Temperature: -40 ° C- + 80 ° C

4. Mobile use bending radius: 7.5D

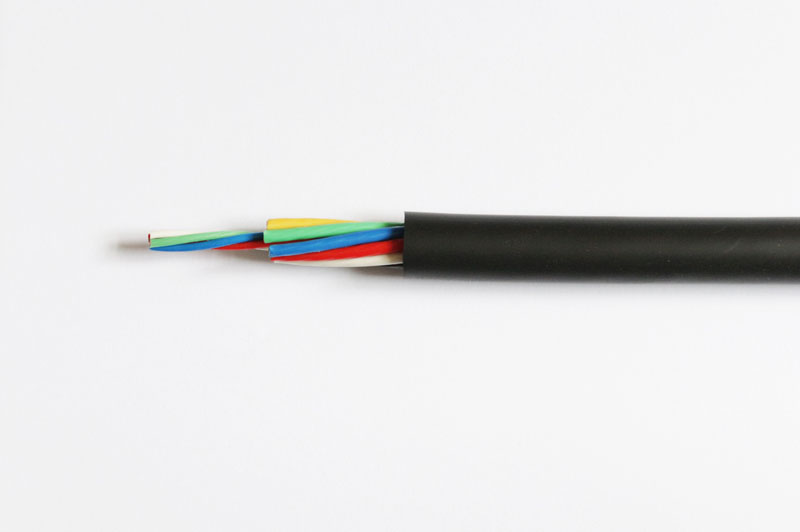

Cable Structure

| Reference Standard | German VDE 0250, PART814 |

| Conductor Material | Bare copper purple line (0.1mm, 0.14mm, 0.19mm, 0.20mm optional) |

| Insulation Material |

>0.3 square nitrile compound PVC <0.3 square imported specialty PE material optionally adding non-metallic tensile conductor |

| Color Standard |

>0.5 square yellow-green ground encoding plus black <0.5 square color-coded |

| Dressing | Non-woven polyester or aluminum foil wrap |

| Inner Jacket | NBR composite PVC, PUR imported special polyurethane elastomer compound |

| Shield | Tinned copper mesh, density 80%, optionally 90% |

| Tensile Braided Layers | An optional Kevlar woven Kevlar braid |

| Outer Sheath | NBR composite PVC, PUR imported special polyurethane elastomer compound |

| Skin Color | Black gray yellow orange |