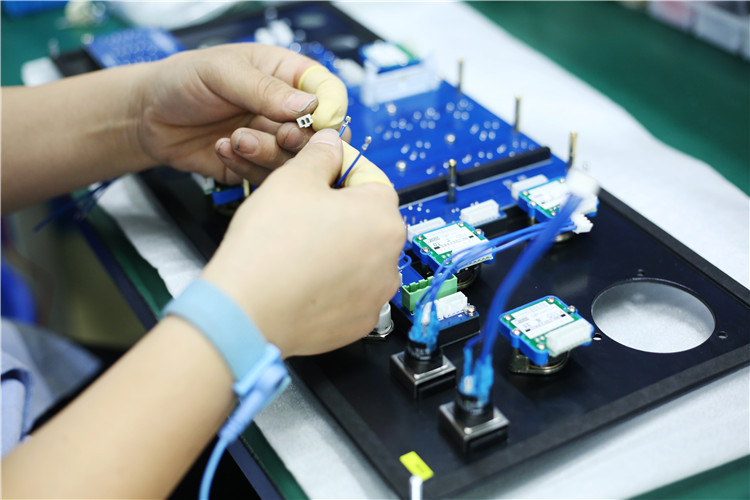

CNC Machining Center Control Panel

Description

Basic Description

CNC machine control panel centralizes all buttons system (it may be referred button station), these buttons are used to directly control the operation of the machine or process, such as start, part program execution is suspended, manual feed axis, adjust feed speed.

Machine control panel with 10 function keys NC, PLC function according to health 12, can be extended key 2, the axis direction key eight, tool display, spindle number, magazine number display function. Control panel provides protection program, key switch function. Mode switch: Jog fast spindle, uses digital band switch

Appications

Application system: Mitsubishi (M70, M70B, M80, M60, M64, E68), Fanuc (FAUNC-0IMD, FAUNC-0I-MATE, 0I-MF).

Applicable models: CNC machining center, milling machine.

Application system: SYNTEC

Applicable models: CNC machining center, milling machine.

Application system: SIEMENS

2. Crystal / film / plastic buttons with digital display with backlight and buzzer

3. Panel function keys arranged freely, the use of "water, oil, dust" Measures

4. You can start having an unlimited number of software encryption / cancellations encryption

5. Each panel has a globally unique ID numbers are confirmed for panels identity.

6. Panel with anti-crack encryption mechanism.

7. Panel provides a variety of PLC programming and distribution solutions for customer’s reference

8. Band switch with gear indicator light changes with the band switch position varies implement touch panel surface mechanical structure and electrical parts completely isolated

9. Key dimpled, ergonomic, more comfortable operation

According to the use of long-distance telephone customers unlock password, no special scene.

Technical Parameters

CNC machine control panel centralizes all buttons system (it may be referred button station), these buttons are used to directly control the operation of the machine or process, such as start, part program execution is suspended, manual feed axis, adjust feed speed.

Machine control panel with 10 function keys NC, PLC function according to health 12, can be extended key 2, the axis direction key eight, tool display, spindle number, magazine number display function. Control panel provides protection program, key switch function. Mode switch: Jog fast spindle, uses digital band switch

Appications

Application system: Mitsubishi (M70, M70B, M80, M60, M64, E68), Fanuc (FAUNC-0IMD, FAUNC-0I-MATE, 0I-MF).

Applicable models: CNC machining center, milling machine.

Application system: SYNTEC

Applicable models: CNC machining center, milling machine.

Application system: SIEMENS

Applicable models: CNC machining center, milling machine, cnc lathe machine

Features

1. Panel with encoding, feel good, fast response, flexible system occupies 16 points input and 16 points output can effectively save the user I / O resource consumption, saving the system I / O cost of procurement2. Crystal / film / plastic buttons with digital display with backlight and buzzer

3. Panel function keys arranged freely, the use of "water, oil, dust" Measures

4. You can start having an unlimited number of software encryption / cancellations encryption

5. Each panel has a globally unique ID numbers are confirmed for panels identity.

6. Panel with anti-crack encryption mechanism.

7. Panel provides a variety of PLC programming and distribution solutions for customer’s reference

8. Band switch with gear indicator light changes with the band switch position varies implement touch panel surface mechanical structure and electrical parts completely isolated

9. Key dimpled, ergonomic, more comfortable operation

According to the use of long-distance telephone customers unlock password, no special scene.

Technical Parameters

Picture

| Operating voltage: | DC24V + 5% |

| Operating Current | 0.8A |

| I / O resource consumption | INPUT 18 bit OUTPUT 18 bit |

| Panel Weight | 2.6 kg |

| Waterproof: | Crystal IP65 / IP67 film |

| Fixed form | Explicit fixed / concealed fixing |

| Hand wheel interface: | integrated panel |

| Signal output: | Coded |

| Effective signal delay time: | 50ms |

| Encryption: | Software lock |

TOP