Vertical Multistage Centrifugal Pump

Description

Vertical Type multi-stage centrifugal pump using standard vertical motor and fast installed mechanical seal, the replacement is very convenient. The over current part of the pump is made of stainless steel (304\316) material, which can be used in the mild corrosive medium. The advantages of compact structure, small size, light weight, low noise, significant energy saving effect, convenient maintenance and so on.

Features

CH series stainless steel multistage centrifugal pump; pump water outlet section material for cast iron (stainless steel), other flow components manufactured by SUS304 and welding equipment, advanced processing, heat treatment and the fire bright annealing furnace, the bottom plate in the tensile stress eliminated by stamping after, so that product high strength deformation and long service life is safe and reliable; meet the sanitary standard for drinking water quality; the special mechanical seal, Water Leakage long time continuous operation; the motor frame is made of high-quality Aluminum Alloy; the low noise, small vibration, long service life; the insulation class F, protection grade IP55, continuous working mode; T1 built-in overheat protector (Dan Xiang), to ensure the safe and convenient use.

Application

1 The transportation of water in the emulsion of cutting fluid on machine tool equipment

2 Processing center

3 Engraving and milling machine

4 Electric spark machine.

5 Numerical control lathe

6 Cold water machine, air conditioning

7 Water treatment filter and other types of equipment

8 Beautiful shape, high quality and durability of the machine tool! One year warranty!

Key words: high pressure machine tool pump, submerged stainless steel multi-stage pump centrifugal pump, vertical multi-stage centrifugal pump, cutting fluid pump

Technical Parameter

Features

CH series stainless steel multistage centrifugal pump; pump water outlet section material for cast iron (stainless steel), other flow components manufactured by SUS304 and welding equipment, advanced processing, heat treatment and the fire bright annealing furnace, the bottom plate in the tensile stress eliminated by stamping after, so that product high strength deformation and long service life is safe and reliable; meet the sanitary standard for drinking water quality; the special mechanical seal, Water Leakage long time continuous operation; the motor frame is made of high-quality Aluminum Alloy; the low noise, small vibration, long service life; the insulation class F, protection grade IP55, continuous working mode; T1 built-in overheat protector (Dan Xiang), to ensure the safe and convenient use.

Application

1 The transportation of water in the emulsion of cutting fluid on machine tool equipment

2 Processing center

3 Engraving and milling machine

4 Electric spark machine.

5 Numerical control lathe

6 Cold water machine, air conditioning

7 Water treatment filter and other types of equipment

8 Beautiful shape, high quality and durability of the machine tool! One year warranty!

Key words: high pressure machine tool pump, submerged stainless steel multi-stage pump centrifugal pump, vertical multi-stage centrifugal pump, cutting fluid pump

Technical Parameter

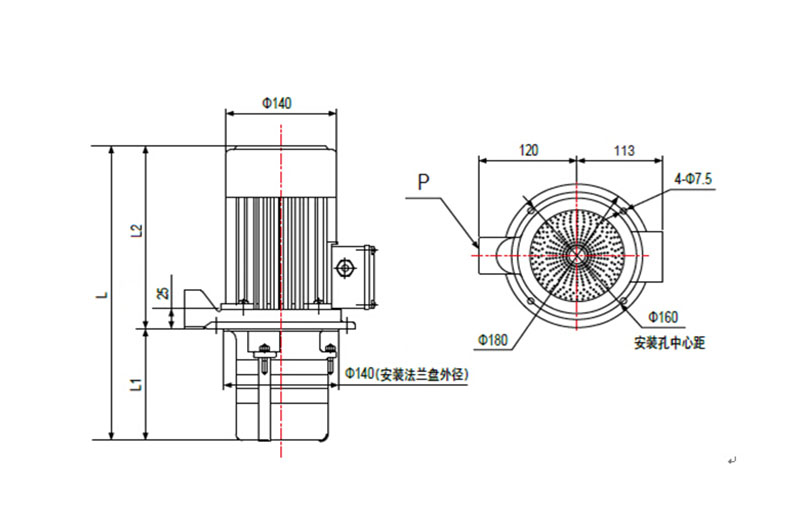

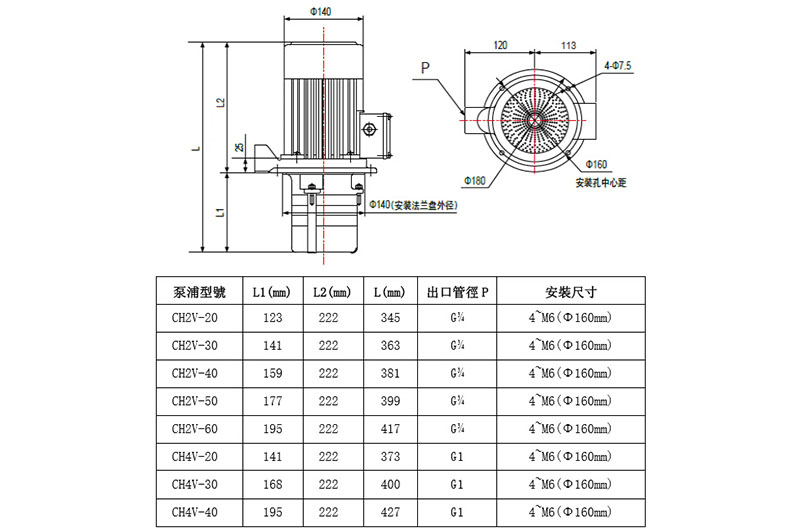

*Note: The distance between the bottom of the pump and the bottom of the water tank is recommended to control the 35mm to 20mm, which is the best performance of the pump.

| Model | Rated Power | Rated Flow | Pump Head | L1 | L2 | L | P(Out Let Diameter) |

|---|---|---|---|---|---|---|---|

| CH2V-30 | 450W | 2 M3/h | 23M | 141mm | 222mm | 363mm | G¾ |

| CH4V-30 | 750W | 4 M3/h | 23M | 168mm | 222mm | 400mm | G1 |

| CH4V-40 | 1000W | 4 M3/h | 30M | 195mm | 222mm | 427mm | G1 |

*Note: The distance between the bottom of the pump and the bottom of the water tank is recommended to control the 35mm to 20mm, which is the best performance of the pump.

TOP