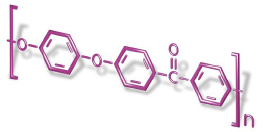

PEEK has high heat resistance as a thermo elastic resin with continuous use temperature of 260°C. Carbon fiber or glass fiber filled grades show HDT of 300°C or more. PEEK is actually used as wafer carriers in semiconductor fields and seal rings of automotive automatic mission where heat resistance and wear resistance are highly requested.

Chemical resistance of PEEK is next to fluoro polymers, furthermore, it is more ductile than fluoro polymers so that PEEK is used as production parts of hard disk manufacturing. It is also used as housing water supply parts thanks to its water-proof property.

Virgin PEEK (unfilled)– is naturally abrasion resistant.

• Unfilled Pellets: DOPEEK®330G(High-flow);550G(secondary-flow);770G(standard-flow)- injection molding, extrusion and other methods.

• Unfilled Coarse Powder: DOPEEK®330P(High-flow);550P(secondary-flow);770P(standard-flow)-extrusion and other methods.• Unfilled Fine Powder: DOPEEK®330PF(High-flow);550PF(secondary-flow);770PF(standard-flow)- Molding and other methods.

Glass Fiber Filled

• DOPEEK®330GL30(High-flow);550GL30(secondary-flow);770GL30(standard-flow)- injection molding, extrusion and other methods.

• DOPEEK®330CA20(High-flow);550CA20(secondary-flow);770CA20(standard-flow)- injection molding, extrusion and other methods.

• DOPEEK®330CA30(High-flow);550CA30(secondary-flow);770CA30(standard-flow)- injection molding, extrusion and other methods.

Wear Grades

>PEEK CF30 (carbon filled)is a 30% carbon filled version of ZY's standard PEEK which offers improved strength and stiffness as well as greater load bearing capabilities for those applications that require it.

>CeramaPEEK® is a proprietary ceramic filled compound created to meet the requirements for tight tolerance, high frequency chip socket test fixtures.

>PEEK (DOPEEK 500) is a high-performance engineering plastic with outstanding resistance to harsh chemicals, and excellent mechanical strength and dimensional stability.

>PEEK Glass-Filled is ZY's 30% glass fiber reinforced DOPEEK product.

Not sure what your options are? please contact us by the form below.

Our experienced sales and technical teams are available to assist you with material selection challenges.