Activated Carbon Fiber Filter Cartridges

2

LFC filter cartridges are manufactured from activated carbon fiber and polypropylene components, developed for decolorization, deodorization and unwanted adsorption, especially for oxidizing substances and organic impurities removal in bottled water industry. They can provide high flow rates at low pressure drops, non-toxic substance releasing and convenience for use. In addition, they are economical alternative to granular activated carbon cartridges.

Features and Benefits

● High throughputs and high adsorption ability

● Broad chemical compatibility

● Easy to regenerate

● No hazardous substances releasing

● Resistant to acids and bases

Quality

● Cartridges produced in a controlled environment

● Manufactured according to ISO9001 certified Quality Management System

Specification

LFC Filter Cartridge for Bottled Water

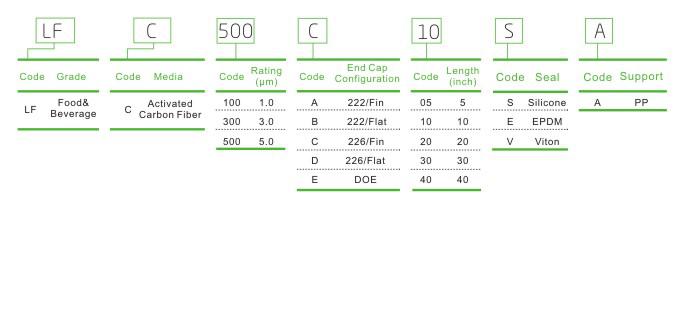

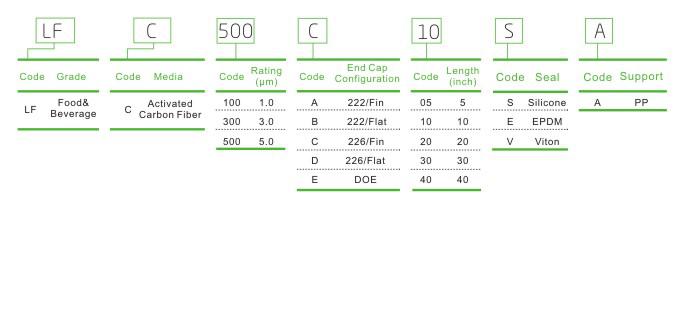

Ordering Information

LFC Filter Cartridge for Bottled Water

Share

LFC filter cartridges are manufactured from activated carbon fiber and polypropylene components, developed for decolorization, deodorization and unwanted adsorption, especially for oxidizing substances and organic impurities removal in bottled water industry. They can provide high flow rates at low pressure drops, non-toxic substance releasing and convenience for use. In addition, they are economical alternative to granular activated carbon cartridges.

Features and Benefits

● High throughputs and high adsorption ability

● Broad chemical compatibility

● Easy to regenerate

● No hazardous substances releasing

● Resistant to acids and bases

Quality

● Cartridges produced in a controlled environment

● Manufactured according to ISO9001 certified Quality Management System

Specification

LFC Filter Cartridge for Bottled Water

| Materials of Construction | |

| Filter Media | Activated Carbon Fiber (ACF) |

| Core, Cage | PP |

| End Caps | PP |

| O-rings/Gasket | Silicone/EPDM/Viton |

| Sealing technology | Thermal Bonding, No Adhesives |

| Dimensions | |

| Diameter | Φ 68 (2.67 in) |

| Length(in) | 5, 10, 20, 30, 40 |

| Filtration Area | |

| ≥ 5.4 ft2/10 in (≥ 0.50 m2/250 mm) | |

| Pore Size, μm | |

| 1.0, 3.0, 5.0 | |

| Maximum Forward Differential Pressure | |

|

4.2 bar@23℃(60.9 psi @73.4℉) 1.5 bar@85℃(21.7 psi @185℉) |

|

| Sanitization | |

| May be hot water sanitized for 15 cycles using purified water at 85℃(185℉) for 30 minutes. | |

Ordering Information

LFC Filter Cartridge for Bottled Water

TOP