Sludge Dehydrator

92

Share

Introduction

Screw press download

Description

DL Sludge dehydrator

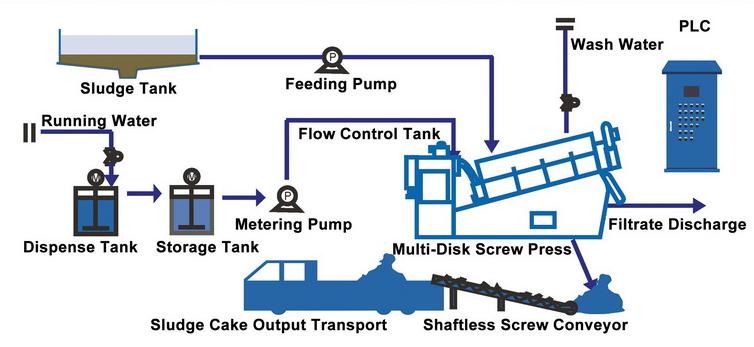

SFC Sludge Dehydrator guide revolutionary technology in industry and municipal wastewater treatment sludge dewatering .

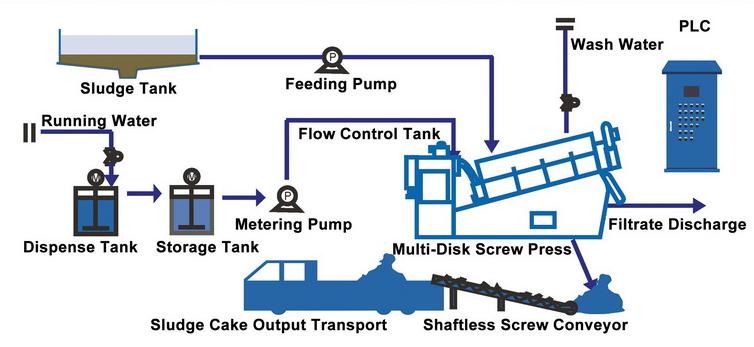

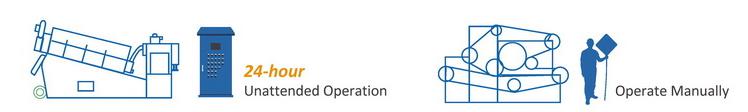

Unique design of the Sludge Dehydrator allows 24 hr unattended operation 7 days per week, Simple process ,high efficiency ,power saving ,low investment make the SFC Sludge Dehydrator widely used in industry and municipal sludge dewatering replace any other kinds of dewatering unit plate fiter press, centrifuge , belt press and so on .

Features

* Simple process ,high efficiency ,power saving ,low investment

* Programme setting makes the operation convenient and accurate

* Exclusive flocculent helps with the dewatering performance

* Accurate chemical preparation and dosage saves much operation cost

Screw Press Superiority (SFC )

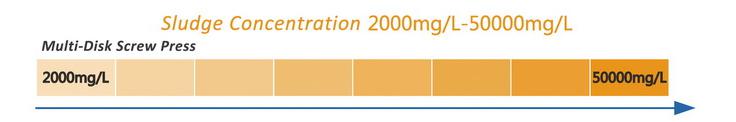

1. Wide application range

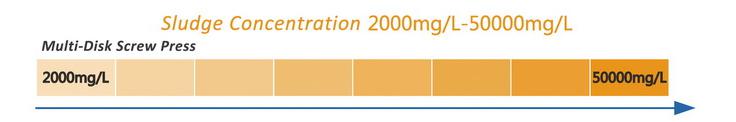

Exclusive pre-concentration design , applicable sludge concentration of 200mg/L~50000mg/L Due to innovation of the structure design .Highly suitable to various high and low concentration sludge most especially the oily ones.

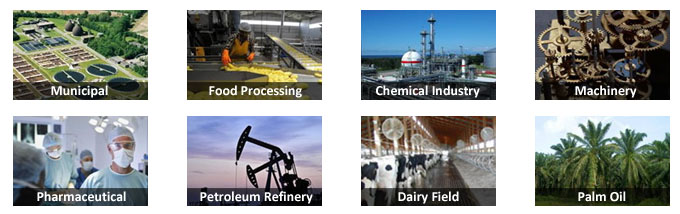

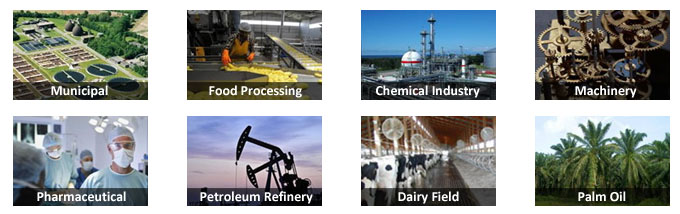

Widely application range including municipal sewage ,food wastewater,slaughter house ,printing and dyeing, oil chemical industry, paper making ,leather ,pharmacy and other different kinds of sludge dewatering.

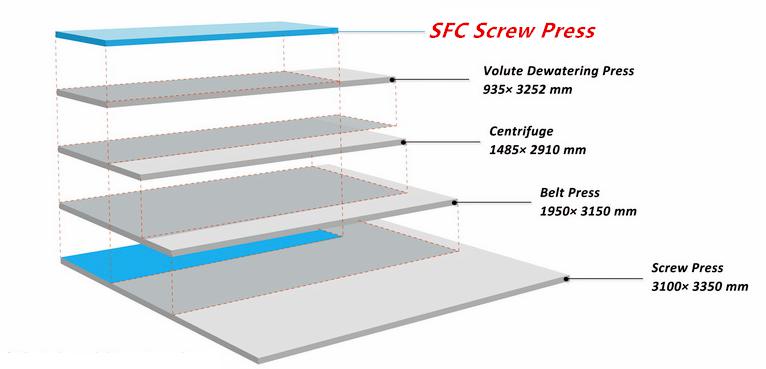

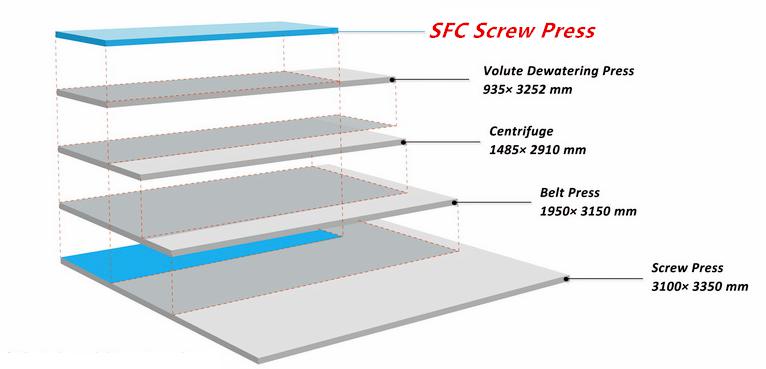

2. Small foot print

SFC Screw Press can be installed in places where placement would not be possible with other technology . What makes SFC Screw Press suitable to cutomers who are considering the replacement of existing sludge dewatering unit .

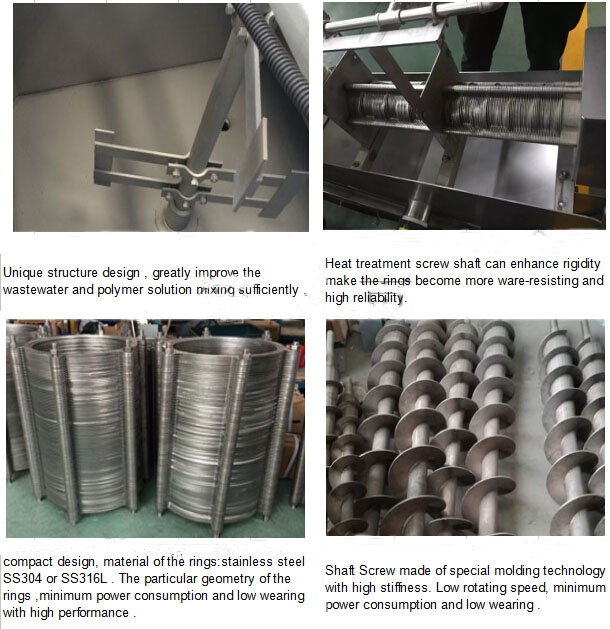

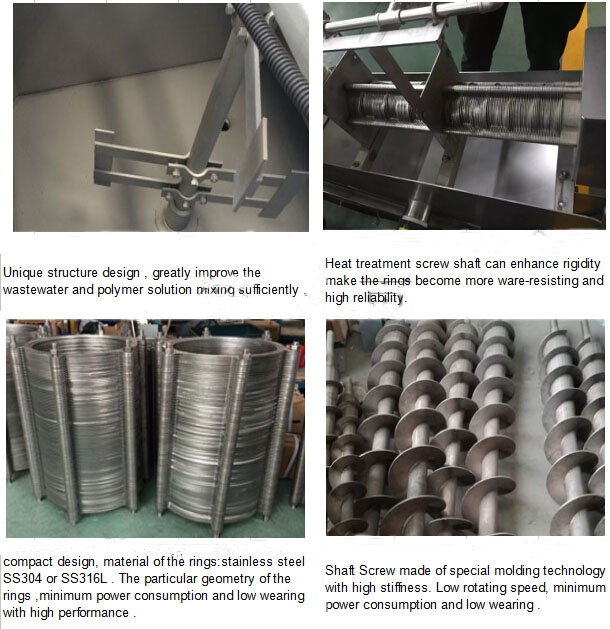

3. No blocking

Due to the moving of the fixed rings and moving rings self -cleaning .The ubiquitous clogging is avoided .Handing oily sludge without trouble while separating the water from the sludge easily . Above all , no need large quantiry of flushing water and no odor ,no secondary pollution during the sludge dewatering process .

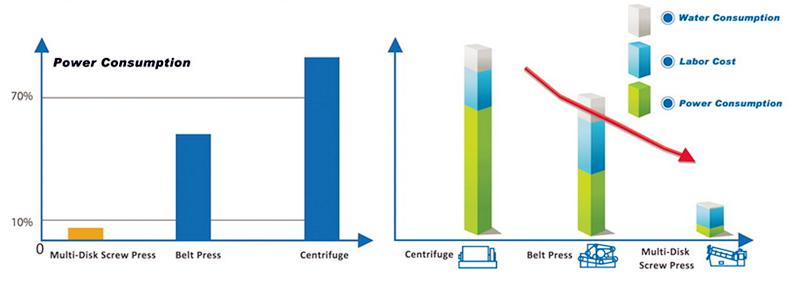

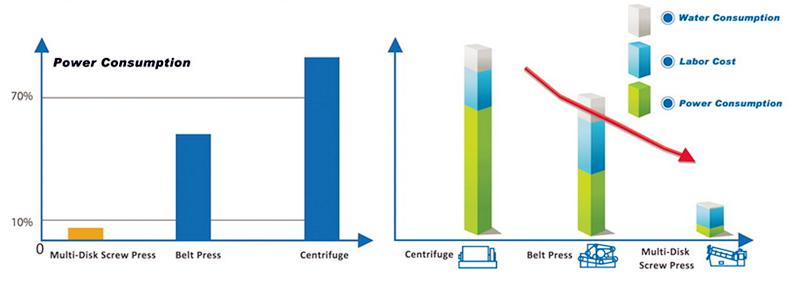

4. Running cost saving

SFC Screw Press relles on the inner pressure of the filter chamber and the rotating speed is as slow as 2~4rpm. The average unit power consumption is only 0.1~0.01kwh/kg-DS(1/8 of Belt Filter Press and 1/20 of Centrifuge) . Greatly reduce the running cost of wastewater treatment system .

5. Fully automatic control

SFC Screw Press equipped without device like filter clothes or filter pore that easy blocked .Operation so easily and can be set to operate automatically via the eletric control cabinet .

6. Super resistance to oily sludge

Self-cleaning mechanism and stainless steel structure enables SFC Screw Press to be the ideal to dewater oily sludge ,which easily causes clogging and is difficult to treat wit other types of dewatering equipments .

Application Field

Technical Data Sheet

DL Sludge dehydrator

SFC Sludge Dehydrator guide revolutionary technology in industry and municipal wastewater treatment sludge dewatering .

Unique design of the Sludge Dehydrator allows 24 hr unattended operation 7 days per week, Simple process ,high efficiency ,power saving ,low investment make the SFC Sludge Dehydrator widely used in industry and municipal sludge dewatering replace any other kinds of dewatering unit plate fiter press, centrifuge , belt press and so on .

Features

* Simple process ,high efficiency ,power saving ,low investment

* Programme setting makes the operation convenient and accurate

* Exclusive flocculent helps with the dewatering performance

* Accurate chemical preparation and dosage saves much operation cost

Screw Press Superiority (SFC )

1. Wide application range

Exclusive pre-concentration design , applicable sludge concentration of 200mg/L~50000mg/L Due to innovation of the structure design .Highly suitable to various high and low concentration sludge most especially the oily ones.

Widely application range including municipal sewage ,food wastewater,slaughter house ,printing and dyeing, oil chemical industry, paper making ,leather ,pharmacy and other different kinds of sludge dewatering.

2. Small foot print

SFC Screw Press can be installed in places where placement would not be possible with other technology . What makes SFC Screw Press suitable to cutomers who are considering the replacement of existing sludge dewatering unit .

3. No blocking

Due to the moving of the fixed rings and moving rings self -cleaning .The ubiquitous clogging is avoided .Handing oily sludge without trouble while separating the water from the sludge easily . Above all , no need large quantiry of flushing water and no odor ,no secondary pollution during the sludge dewatering process .

4. Running cost saving

SFC Screw Press relles on the inner pressure of the filter chamber and the rotating speed is as slow as 2~4rpm. The average unit power consumption is only 0.1~0.01kwh/kg-DS(1/8 of Belt Filter Press and 1/20 of Centrifuge) . Greatly reduce the running cost of wastewater treatment system .

5. Fully automatic control

SFC Screw Press equipped without device like filter clothes or filter pore that easy blocked .Operation so easily and can be set to operate automatically via the eletric control cabinet .

6. Super resistance to oily sludge

Self-cleaning mechanism and stainless steel structure enables SFC Screw Press to be the ideal to dewater oily sludge ,which easily causes clogging and is difficult to treat wit other types of dewatering equipments .

Application Field

| Specification | DL Series Screw Press | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| DL-101 | DL-102 | DL-201 | DL-202 | DL-301 | DL-302 | DL-303 | DL-401 | DL-402 | DL-403 | ||

| Treating Capacity (m3/hr) SS0.4~3.5% | 0.1~1.25 | 0.2~2.5 | 0.4~3.75 | 0.9~7.5 | 1.4~12.5 | 2.8~25 | 4.2~37.5 | 4~37.5 | 8~75 | 12~112 | |

| Dried Sludge D.S. (Kg./hr) | 3~5 | 6~10 | 9~15 | 18~30 | 30~50 | 60~100 | 90~150 | 90~150 | 180~300 | 270~450 | |

| Water Content Rate (%) | 75~85 | 75~85 | 75~85 | 75~85 | 75~85 | 75~85 | 75~85 | 75~85 | 75~85 | 75~85 | |

| Screw specification (mm)*Quantity of roots | 100*1 | 100*2 | 200*1 | 200*2 | 300*1 | 300*2 | 300*3 | 400*1 | 400*2 | 400*3 | |

| Power Consumption (KW) | 0.2 | 0.4 | 0.4 | 0.75 | 0.8 | 1.2 | 1.95 | 1.95 | 2.95 | 4.4 | |

| External Dimensions (mm) | L | 1816 | 1816 | 2500 | 2500 | 3255 | 3455 | 3605 | 5000 | 5000 | 5400 |

| W | 756 | 910 | 850 | 935 | 985 | 1295 | 1690 | 1120 | 1660 | 2240 | |

| H | 1040 | 1040 | 1270 | 1270 | 1600 | 1600 | 1600 | 2400 | 2400 | 2400 | |

| Reference Weight (kgs) | 190 | 275 | 360 | 470 | 820 | 1350 | 1820 | 3200 | 4100 | 4980 | |

TOP