RFID Card Inlay

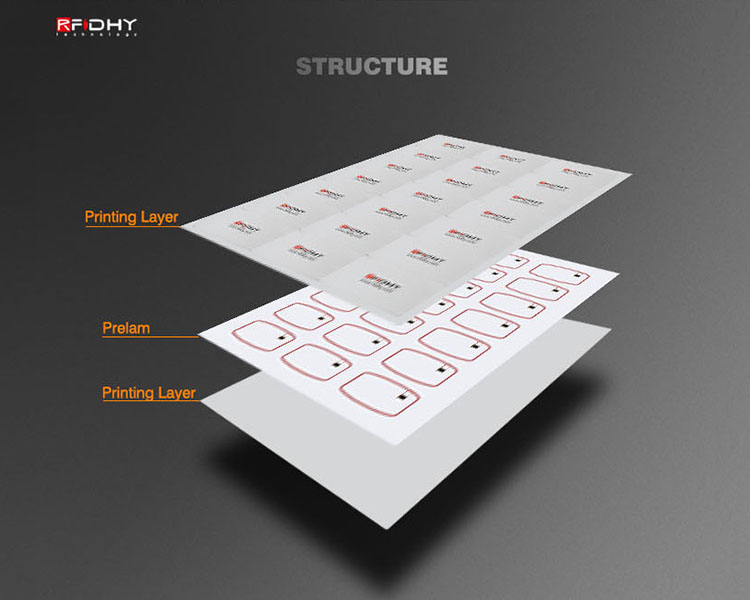

Prelaminated inlay Combi are designed specifically with the card manufacturer in mind.

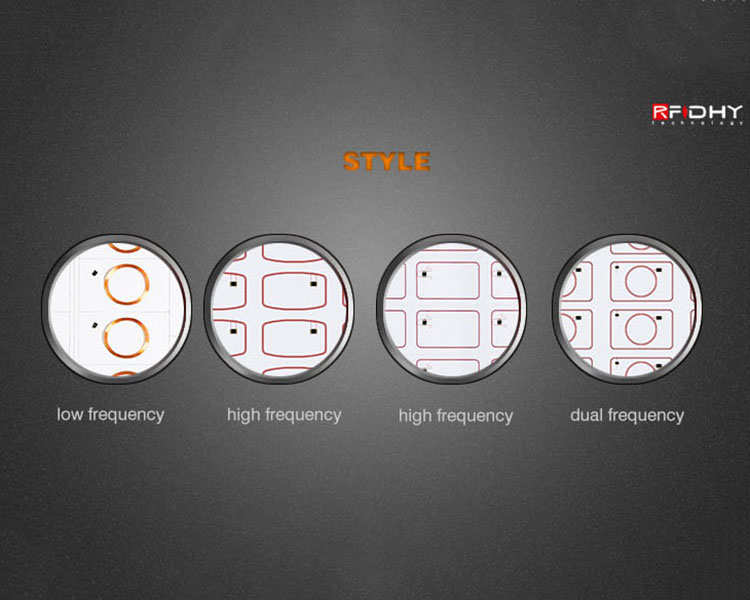

RFID inlay Combi consist of two or even more different chip technologies, offering combinations of HF + LF, HF + UHF or LF + UHF chips in one card. Even a contact chip module can be embedded if the layout is designed accordingly.

Product Description

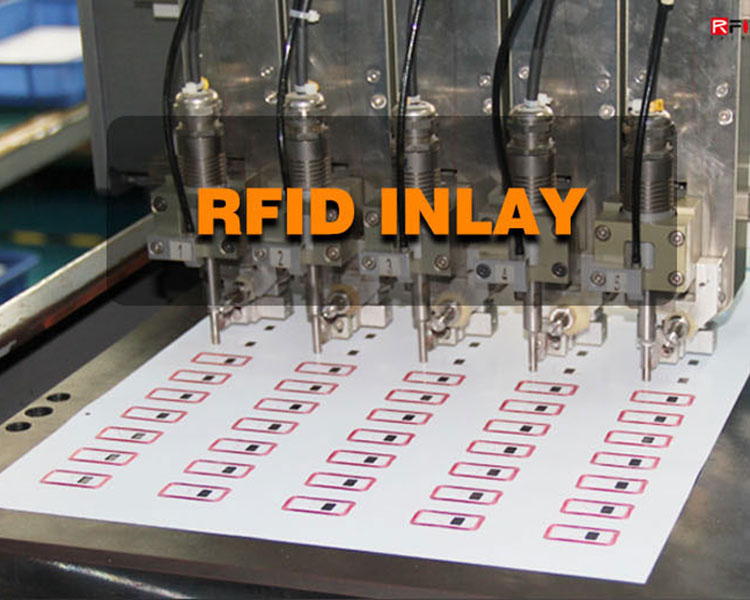

Prelaminated rfid inlays are suitable for use in the production of ISO standard cards. RFIDHY uses a proprietary manufacturing process to produce its prelaminated rfid inlays.

Our rfid inlays are very robust and boast unequaled torsion / bending characteristics, extreme durability and optimized read / write performance. The inlays have a completely flat finish and bring numerous benefits to card manufacturers.

Our rfid inlay is essentially a semi-finished product, so that the card manufacturer merely needs to collate his printed sheets with the inlay and laminate the “sandwich”.

Features

• Very reliable and robust plastic package

• High reading distance optimized to each chip

• Materials: PVC, PETG, PC

• Colour: white or transparent

• Option of combining two different chip technologies in one prelam

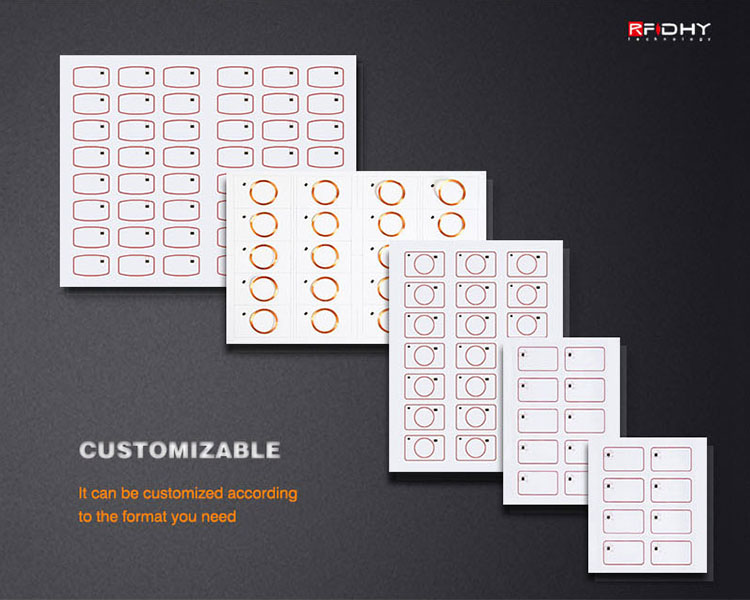

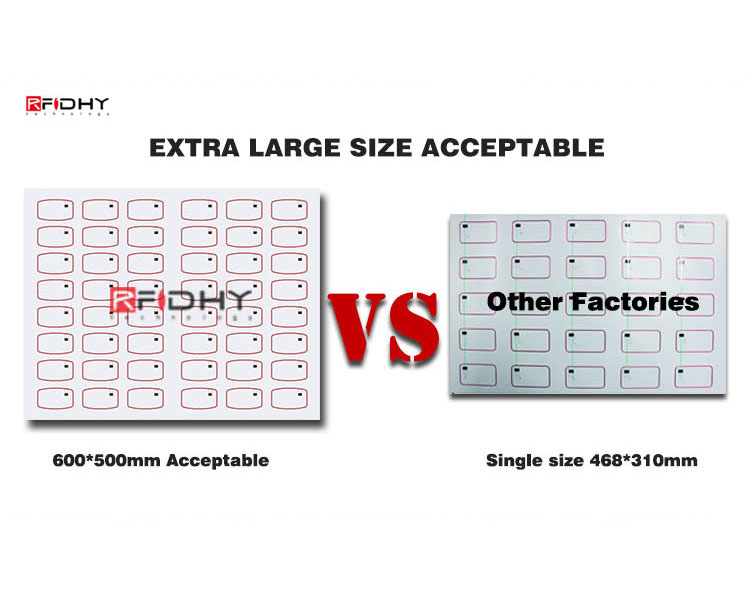

• Different sheet formats are available 1 × 5, 2 × 5, 3 × 6, 3 × 7, 3 × 8, 3 × 10, 4 × 10 up to 640 × 520 mm, others upon request

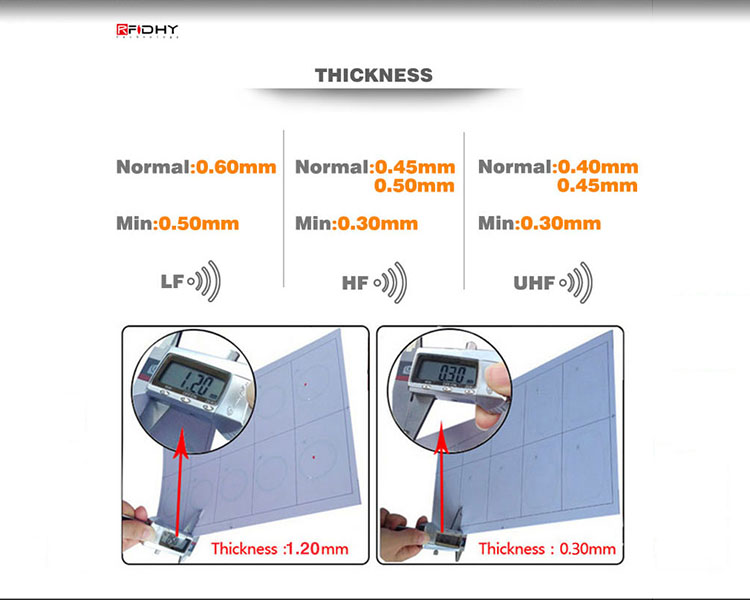

• Thickness: LF+HF(0.6mm), LF+UHF(0.55~0.6mm), HF+UHF(0.5mm)

Features Examples of application

• Physical access

• Logical access

• Public transport

• City card

• Student card

• E-purse systems

Available chip technologies

Other ICs are available upon request.

RFID inlay Combi consist of two or even more different chip technologies, offering combinations of HF + LF, HF + UHF or LF + UHF chips in one card. Even a contact chip module can be embedded if the layout is designed accordingly.

Product Description

Prelaminated rfid inlays are suitable for use in the production of ISO standard cards. RFIDHY uses a proprietary manufacturing process to produce its prelaminated rfid inlays.

Our rfid inlays are very robust and boast unequaled torsion / bending characteristics, extreme durability and optimized read / write performance. The inlays have a completely flat finish and bring numerous benefits to card manufacturers.

Our rfid inlay is essentially a semi-finished product, so that the card manufacturer merely needs to collate his printed sheets with the inlay and laminate the “sandwich”.

Features

• Very reliable and robust plastic package

• High reading distance optimized to each chip

• Materials: PVC, PETG, PC

• Colour: white or transparent

• Option of combining two different chip technologies in one prelam

• Different sheet formats are available 1 × 5, 2 × 5, 3 × 6, 3 × 7, 3 × 8, 3 × 10, 4 × 10 up to 640 × 520 mm, others upon request

• Thickness: LF+HF(0.6mm), LF+UHF(0.55~0.6mm), HF+UHF(0.5mm)

Features Examples of application

• Physical access

• Logical access

• Public transport

• City card

• Student card

• E-purse systems

Available chip technologies

| Manufacturer/Frequency | 125 kHz | 13.56 MHz | 860-960Mhz |

| EM Microelectronic | EM4102, EM4200, EM4305, EM4450 | ||

| NXP | Hitag®1, 2, S | MIFARE Ultralight®, MIFARE® Classic, MIFARE® DESFire®, MIFARE Plus®, I-Code®: SLI | |

| Infineon | MIFARE®: SLE66R35 | ||

| Atmel | ATA5575M1, ATA5575M2, ATA5577, Q5 | ||

| Legic® | Prime: MIM256, MIM1024 | ||

| Impinj | Monza 4, Monza 5 | ||

| Alien | Alien H3, H4 |

TOP