Specifications and Sizes:

|

Product name |

Fireproof Coating Aluminum Composite Panel |

| Aluminum Alloy | AA1100, AA3003, AA5005 |

| Al sheet thickness | From 0.25mm*0.25mm to 0.5mm*0.5mm |

| Panel thickness | From 3mm to 6mm |

| Panel width | 1000mm & 1220mm & 1250mm & 1500mm & 1575mm |

| Panel length | Upon customs' request |

| Color | Upon customs' request |

|

Service |

OEM and ODM are available |

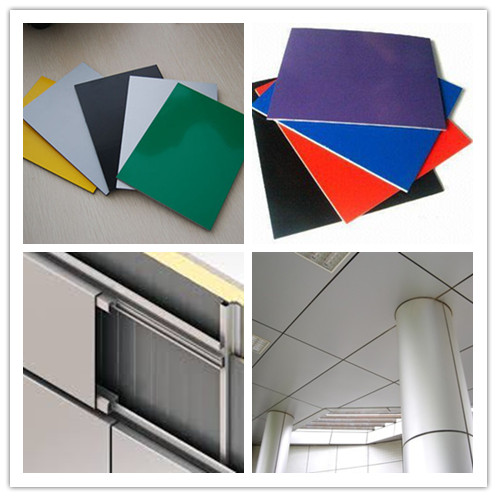

Aluminum Composite Panel Applications:

| A | Building exterior curtain walls |

| B | Decoration and renovation additions for old buildings |

| C | Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

| D | Shop door decorations |

| E | Advertisement board display platforms and signboards |

| F | Wallboard and ceilings for tunnels |

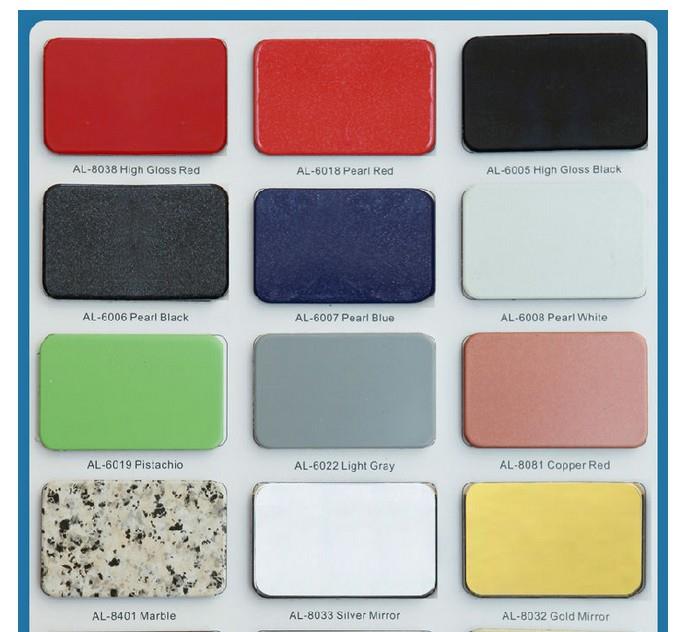

Available Colors:

We can produce all colors on all professional color cards

Aluminum Source:South West Aluminum Factory

Painting Source:PPG&BECKER

PE core Material:Non-toxicand low-density Polyethylene

Payment Term:TT, LC at sight,D/P,Western Union,Paypal

Production Capability:250000SQM/Month

More Service:OEM, Samples free(samples will be sent in one day time )

Feature:Super peeling strength/ Good temperature adaptability/ Excellent performance of fireproof/ Weather proof/ Quickly installed/ Excellent self-cleaning character

Applications:

A. Building exterior curtain walls

B. Decoration and renovation additions for old buildings

C. Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

D. Shop door decorations

E. Advertisement board display platforms and signboards

F. Wallboard and ceilings for tunnels

Assurance:

1. Goods Inspection: We have professional inspection team to Cooperate with the SGS Laboratory assigned by customer to do the goods inspection.

2. Quality Assurance: We keep the production samples as well as the corresponding test data for customer’s inspection in the future.

3. Goods Return Service: We provide free replacement for goods incompliance with committed quality.

4. Response time: We promise respond to customer goods incompliance report as soon as possible within 24 working hours.

Certification:

Greenbond has a complete strict quality assurance system, as well as successfully passed ISO 9001 and ISO 2001 certifications.

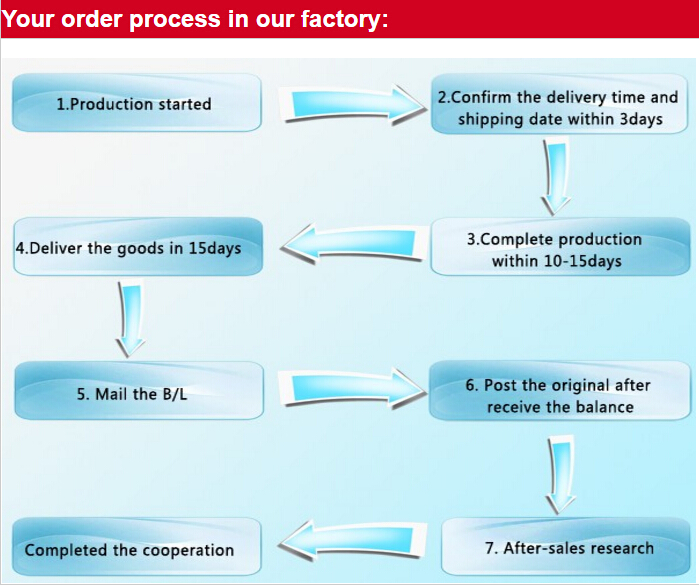

Packing & Delivery

Packing Details : packed in bulks or wooden box,suitable for shipping container

Delivery Details : It need about 25 days after receiving your deposit

Test Report on Physical Characteristies of State Thst Center of Building Materials

| Items | Standard Inde | Test Value | Individual Judgment |

|---|---|---|---|

| Density of surfac | Rating±0.5kg/m2 | 6.8kg/m2 | Qualified |

| Impact strength | 50kg.cmWithout paint off and crack | Without paint off and crack | Qualified |

| Bend strength | ≥ 1OOMPa | ≥ 1O4MPa | Qualified |

| Flexuous modulus of elasticity | ≥2.00 x lO4MPa | 3.00 x lO4MPa | Qualified |

| Through resistance | ≥9.0KN | 9.50KN | Qualified |

| Cutting strength | ≥ 28.OMPa | 29.OMPa | Qualified |

| 1800peel strength | ≥7.0N/mm | ≥9.1N/mm | Qualified |

| Resistance to change of temperature | -400C~-800C20cycles without change | Unchanged | Qualified |

| Boiling water resistance | Unchanged | Unchanged | Qualified |

| Coefficient of heat expansion | ≥4.00 X lO-5 0C-1 | 2.93 X lO-5 0C-1 | Qualified |

| Heat deformation temperature | ≥1050C | 1120C | Qualified |

| The test result meets the index requirements of quality product of GB/T17748-1999 | |||

Test Report of Safety of State Quality Supervision & Inspection Center of Fireproof Building Materials

Fireproof Aluminum Composite Panel

| Items | Test method | Technical index | Result | Conclusion |

|---|---|---|---|---|

| Minmum value of remaining length after burning | GB/T8325-88 | > 0 | 410 | Qualified |

| Average value of remaining length after burning | GB/T8325-88 | ≥ 150 | 486 | Qualified |

| Temperature of smoke | GB/T8325-88 | ≤ 200 | 116 | Qualified |

| Height of the top of the flame,mm | GB/T8326-88 | 〈 150 | 15 | Qualified |

| Grade of smoke density | GB/T8327-88 | ≤ 75 | 34 | Qualified |

|

Note:The technical index based on the regulation of uninflammable materials(Grade B1)of GB8624-1997. |

||||

Advantages of High Glossy ACP

Advantages of High Glossy ACP

Quickly installed

Low and High Temperature Resistance

Colorful

Not easy to fade

Not easy to fade

Light Weight and Easy for Process

Coating Evenness & Diversified Colors

Superior Weathering Resistance

Excellent self-cleaning character

High Mechanical Strength and Toughness

Anti-fungus

Easy for Maintenance

Project show:

Greenbond has many clients around the world. Here is the beautiful pictures of project shows.

Other project show:

Greenbond aluminium composite panel is ideal to be used for office buildings, shopping centers, industrial buildings, airports, hotels, bus stations, hospitals, schools, supermarkets, and residential buildings.

2. If you meet any product issues or questions, please directly contact with us immediately, We will arrange commissioner, timely follow up within 24 hours, and feedback. For examples, If you meet quality problems, please kindly do you utmost offer more details like pictures. Below solutions for your reference,

Solution A: The problems is small, the same quantity product will be dispatched to you in new shipment.

Solution B: The problems is big, return all goods values, meanwhile, we will pay for all installation charges for the problem ACP.

3, We regularly in terms of product satisfaction questionnaire, you are warmly welcome to provide any comments or Suggestions for our product or services, we will improve it in time, and present a exquisite gift for you to show our appreciation.

Claim: If you meet any problems when you use, please feel free to communicate with us, it is our biggest pleasure to support you in all terms. Any problems you feedback will be our the ladder of progress. Welcome to buy our products again, we will continue to provide quality and convenient service for you.

- PVDF Coating Aluminum Composite Panel

- PE Coating Aluminum Composite Panel

- High Glossy Aluminum Composite Panel

- Signboard Aluminum Composite Panel

- Wooden Aluminum Composite Panel

- Marble Aluminum Composite Panel

- Mirror Aluminum Composite Panel

- Fireproof Aluminum Composite Panel

- Brushed Aluminum Composite Panel

- Nano Aluminum Composite Panel

- Unbreakable Aluminum Composite Panel

- Silicone