FBU type 2260 cartridge mechanical seal alternative to SB2

2260 is a dual cartridge seal. Its double-balanced design ensures the reliability and longevity of the seal in the

most demanding conditions.

ideal for use with environmentally hazardous and abrasive fluids, most often used in pumps in pulp mill area for cooking, evaporation and causticising.

compatible withother kinds of pumps and process equipment including agitators.

Features

1. The springs are located in the stationary body

2. ± 2 mm axial movement.

3. Protected faces

The seal face carriers are driven by machined fits,

preventing metal stress from distorting the face.

FBU was established in 2007, with FBU trademark and is constantly developing series of

cartridge seals conforming to standards of ISO , ANSI, DIN, and API ,which are

widely used in industry such as chemical processing, paper & pulp, Iron Mine,

marine and food processing.

Our core

business is cartridge

mechanical seals and seal supporting

system, FBU can

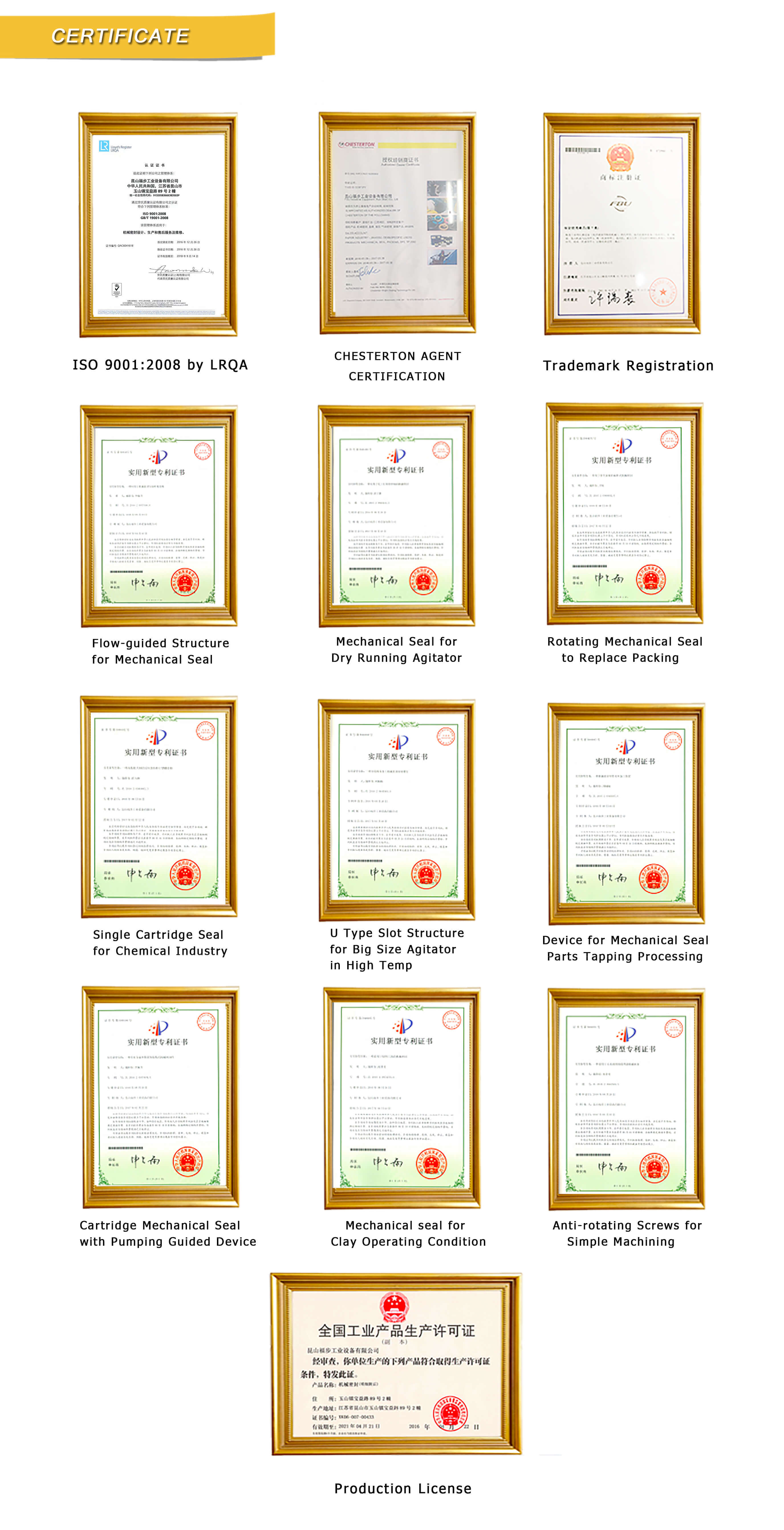

design, manufacture, and recondition mechanical seals as per ISO 9001:2008 LRQA

assessed management.

Choose FBU, find us to save your Time and Money.

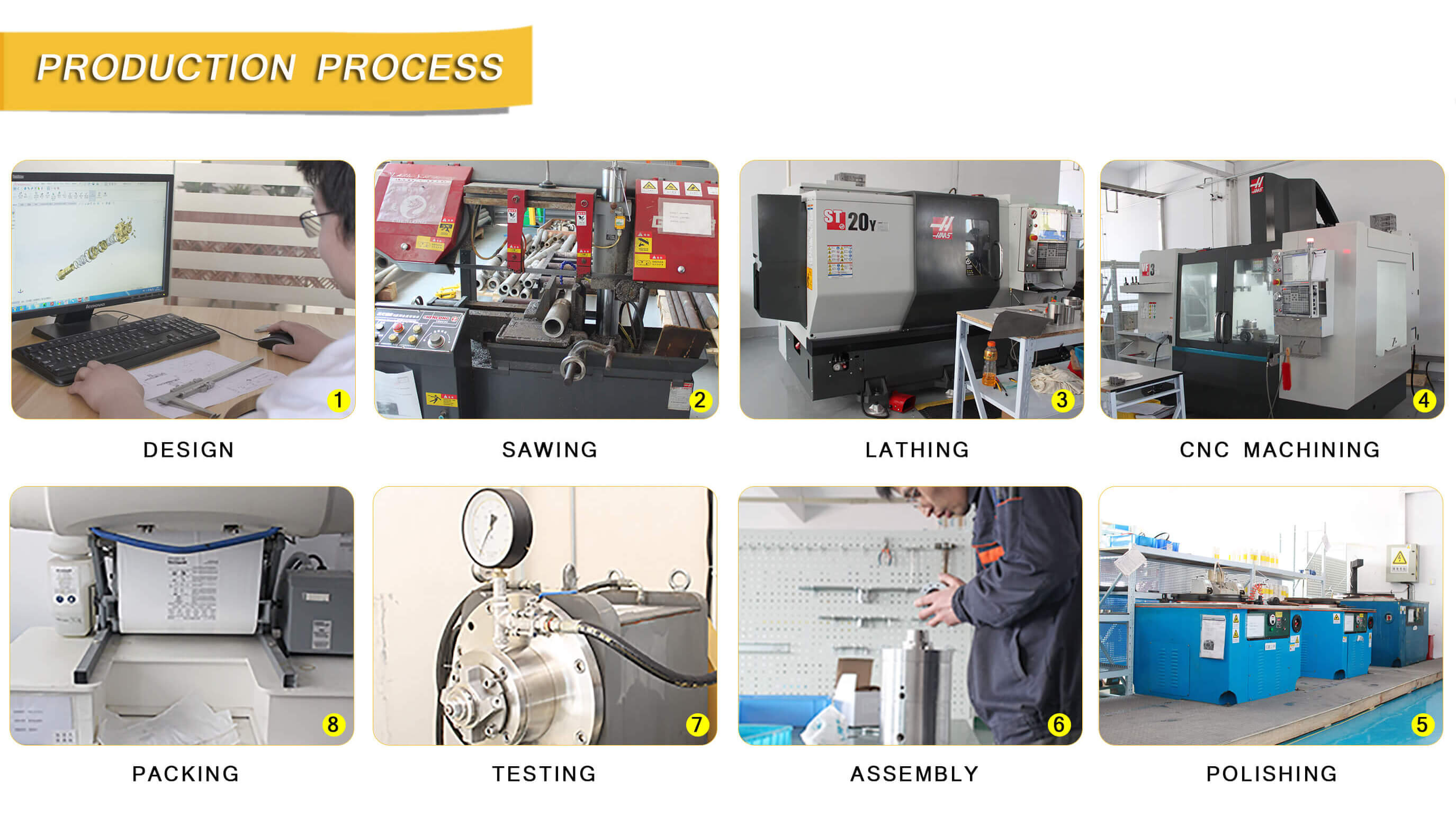

How we do our jobs ???

Want to know more about us, kindly feel at free to sale@fbuseals.com

| Materials of Construction | |

|---|---|

| Rotating Face: |

Sintered Silicon Carbide |

| Stationary Face: | Sintered Silicon Carbide |

| Elastomers: |

Viton® Standard |

| Aflas® or Kalrez ® | |

| Metal Parts: | 316 S.S. |

| Springs: |

316 S.S. |

| Operating Conditions | |

| Size: |

25mm~100mm |

| Temperature: | 325°C |

| Speed: | 3600 RPM |

| 2900 RPM | |

| 1800 RPM | |

| Pressure: | 25 BAR |

| Runout: | Up to .060 (1.5 mm) TIR |

| Radial movement | |

Want to know more about FBU, welcome to contact us at sale@fbuseals.com