FBU type 3400 double cartridge seal alternative to AES CDPH for South Africa mine

Double heavy duty slurry seal

• Solid drive mechanism and thicker sections to deal with the most arduous duties

• Metal to metal fits

• Large Quench and Drain ports to enhance heat r emoval

• Large radial clearances

• Hydraulically balanced seal faces

SEAL ORIENTATION: Horizontal or Vertical**

** Care should be taken to bleed the outboard seal faces if mounted vertically

OPERATING CONDITIONS

• Temperature: Up to 180ºC (356ºF)

(Application and Seal Material Dependent)

• Pressure : 0.34barg (5psig) to 20 barg (290 psig)

• Speed : Upto 20 m/s (4000 ft/min)

APPLICATION AREAS

• Double Heavy Duty Slurry Seal

• Typical equipment includes Warman, Denver Orion, Gould’s, KSB

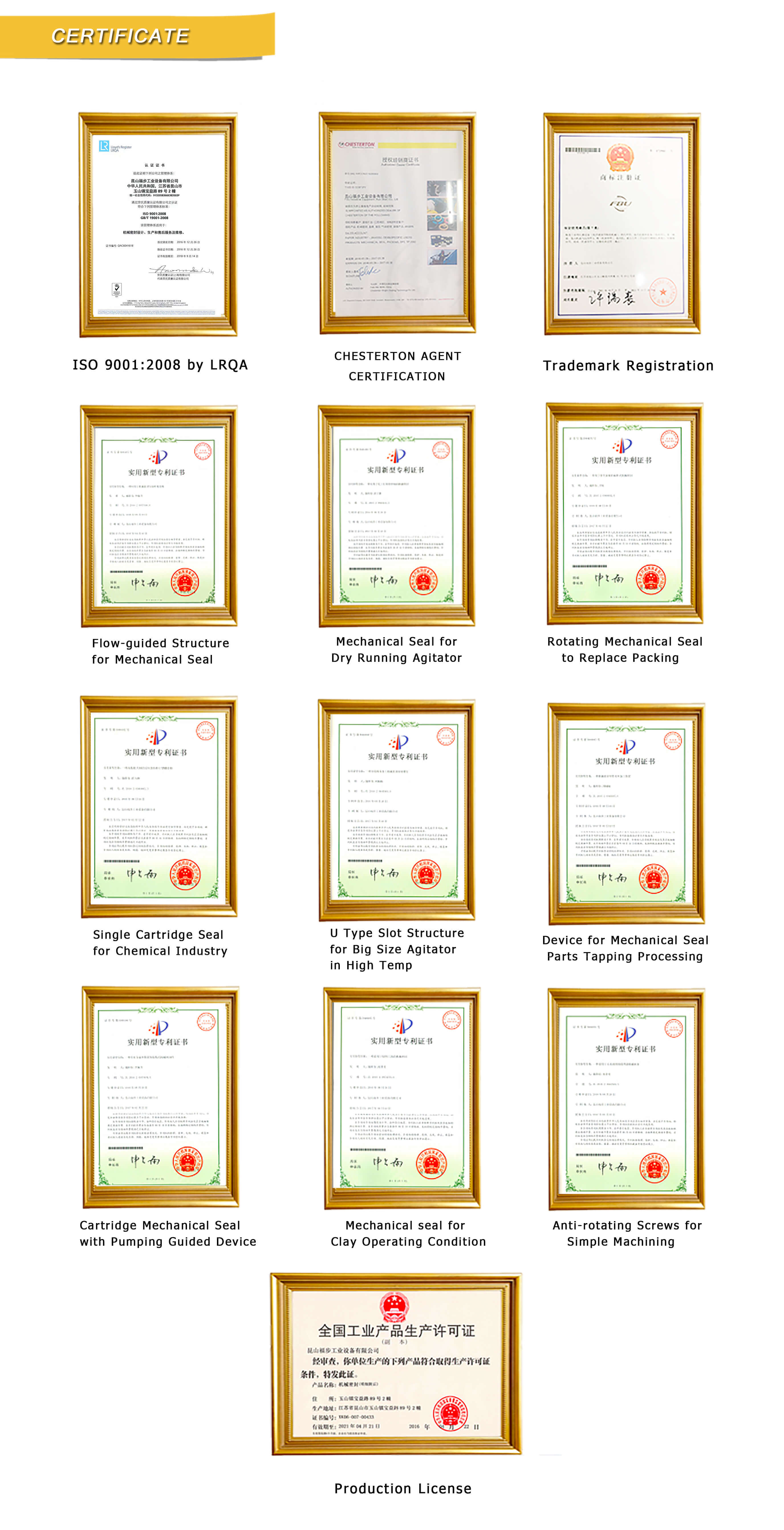

FBU was established in 2007, with FBU trademark and is constantly developing series of cartridge seals conforming to standards of ISO , ANSI, DIN, and API ,which are widely used in industry such as chemical processing, paper & pulp, Iron Mine, marine and food processing.

Our core business is cartridge mechanical seals and seal supporting system, FBU can design, manufacture, and recondition mechanical seals as per ISO 9001:2008 LRQA assessed management.

Choose FBU, find us to save your Time and Money.

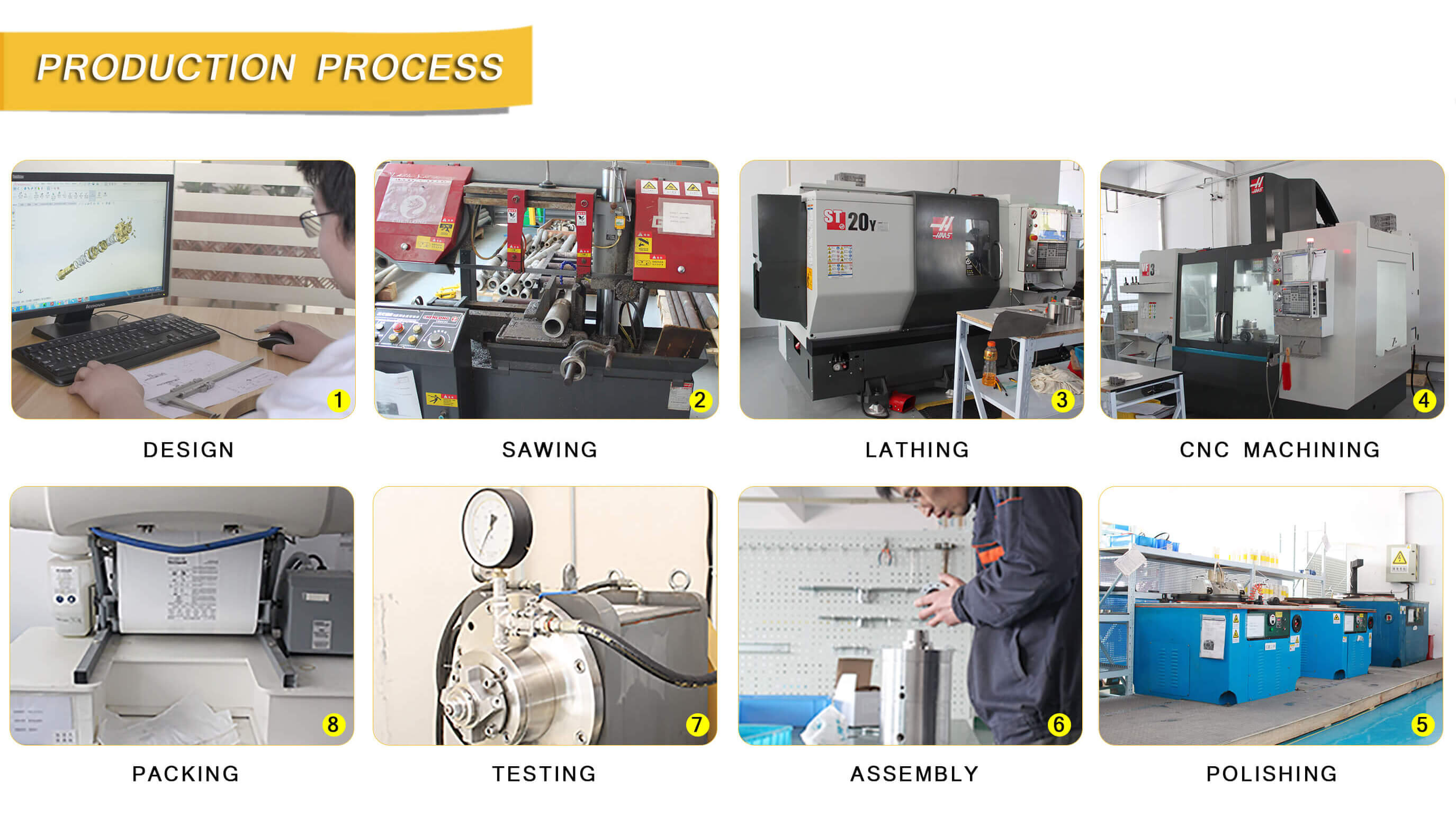

How we do our jobs ???

Want to know more about us, kindly feel at free to sale@fbuseals.com

| Materials of Construction | |

|---|---|

| Rotating Face: |

Sintered Silicon Carbide |

| Stationary Face: | Sintered Silicon Carbide |

| Elastomers: |

Viton® Standard |

| Aflas® or Kalrez ® | |

| Metal Parts: | 316 S.S. |

| Springs: |

316 S.S. |

| Operating Conditions | |

| Size: |

100mm |

| Temperature: | 150°C |

| Speed: | 3600 RPM |

| 2900 RPM | |

| 1800 RPM | |

| Pressure: | 25 BAR |

| Runout: | Up to .060 (1.5 mm) TIR |

| Radial movement | |

Want to know more about FBU, welcome to contact us at sale@fbuseals.com