What

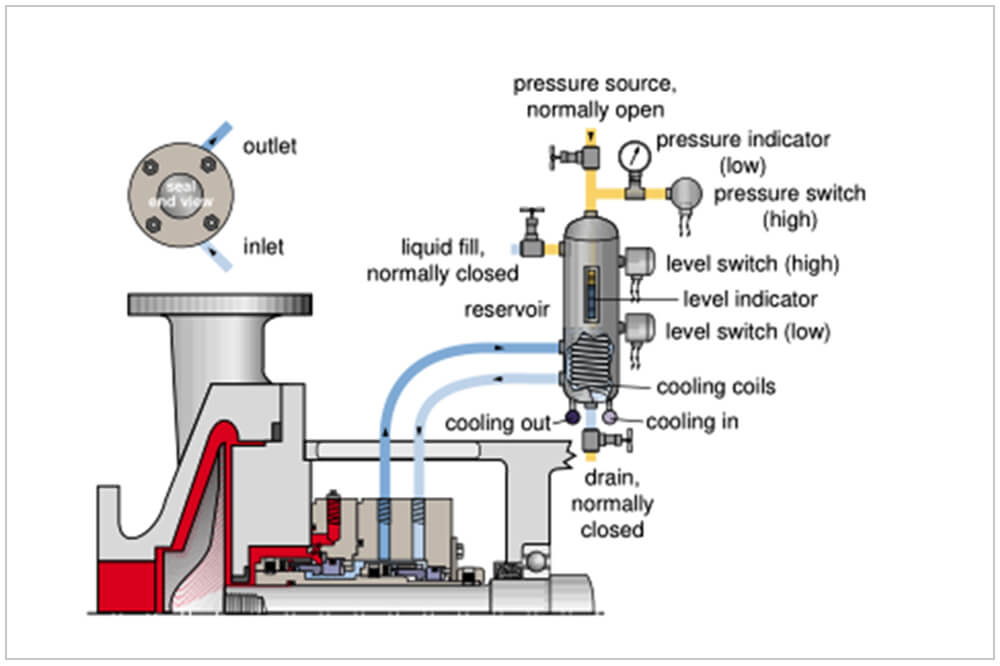

Pressurized barrier fluid circulation through reservoir.

Fluid is circulated by a pumping ring in the dual seal assembly.

Why

Isolate process fluid.

Zero process emissions.

Where

Used with dual pressurized seals (“double”).

High vapor pressure fluids, light hydrocarbons.

Hazardous/toxic fluids.

Heat transfer fluids.

Dirty/abrasive or polymerizing fluids.

Mixers/agitators and vacuum service.

Preventative Maintenance - Reference Appendix B

Piping loop must self-vent to reservoir located at highest elevation.

Pressurize reservoir at all times, maximum gas charge 150 - 200 psi (10 - 14 bar).

Barrier fluid must be compatible with process.

Reservoir level indicator shows both inboard and outboard seal leakage.

FBU was established in 2007, with FBU trademark and is constantly developing series of cartridge seals conforming to standards of ISO , ANSI, DIN, and API ,which are widely used in industry such as chemical processing, paper & pulp, Iron Mine, marine and food processing.

Our core business is cartridge mechanical seals and seal supporting system, FBU can design, manufacture, and recondition mechanical seals as per ISO 9001:2008 LRQA assessed management.

Choose FBU, find us to save your Time and Money.

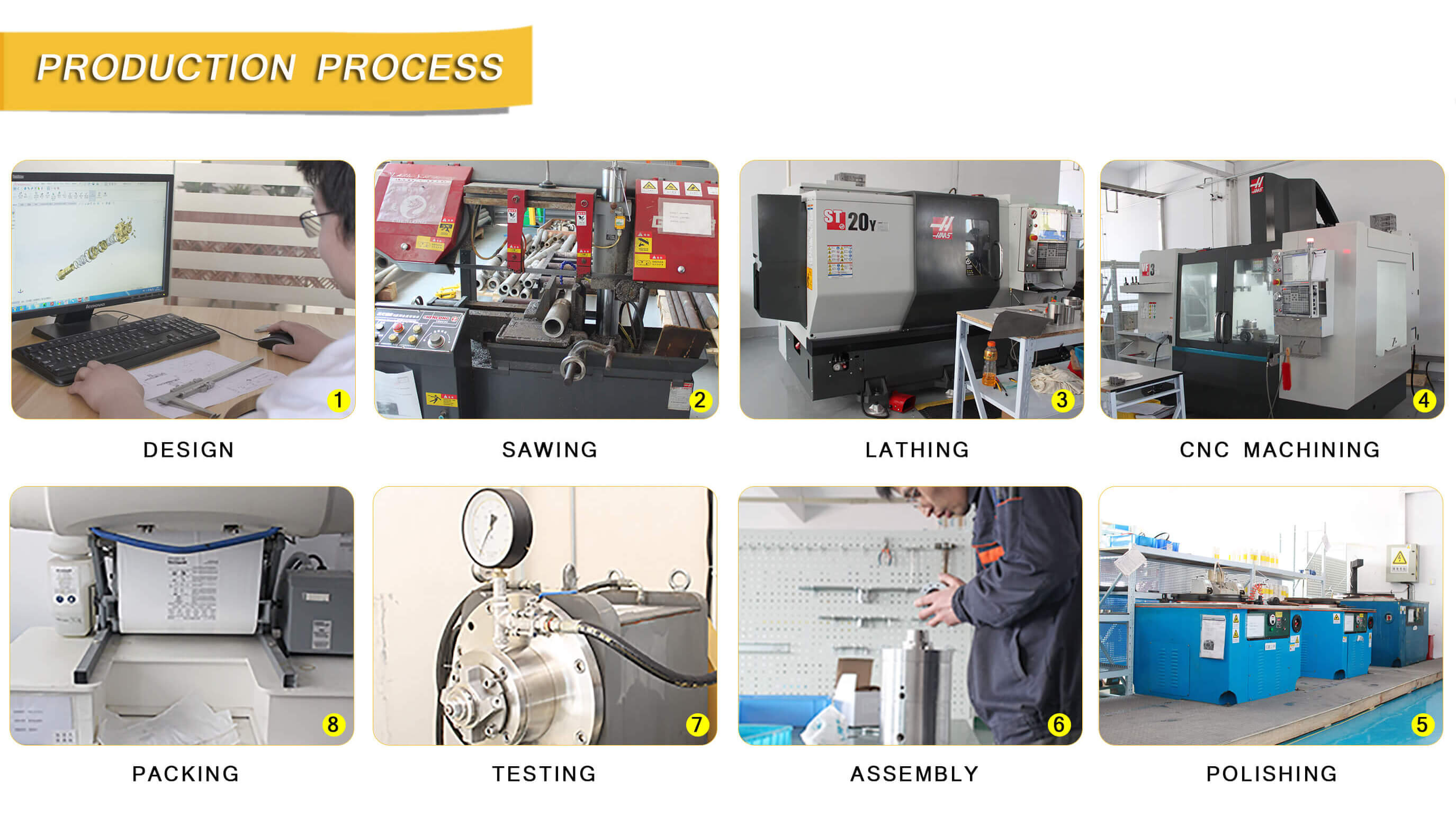

How we do our jobs ???

Want to know more about us, kindly feel at free to sale@fbuseals.com

Want to know more about FBU, welcome to contact us at sale@fbuseals.com