Experienced in manufacturing customized metal stamping parts for your special requirement in Electrocommunication, Medical, Household Appliances, Furniture industry, Machinery industry, instrument and meter industries etc.

JM offers a variety of precision punch, CNC punch, CNC folding machine, laser cutting equipment, oxygen cutting equipment and all kinds of welding equipment.

|

|

|

|

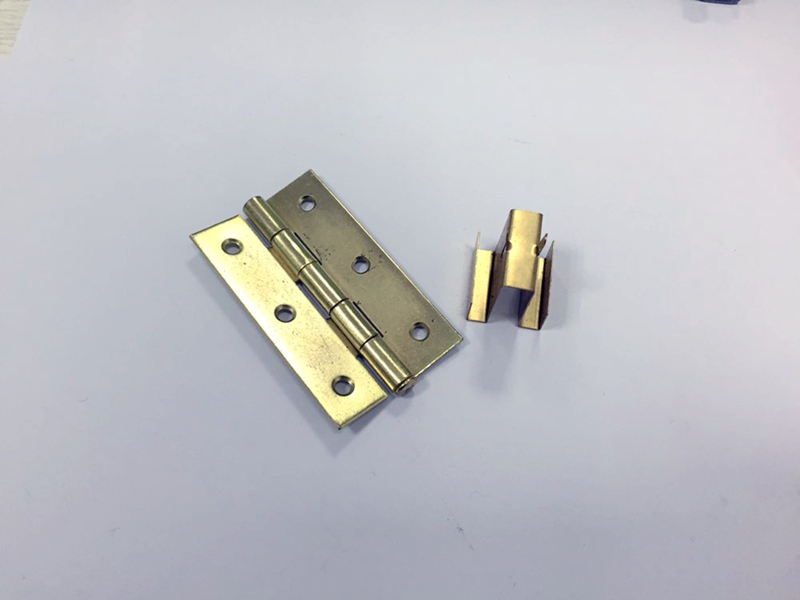

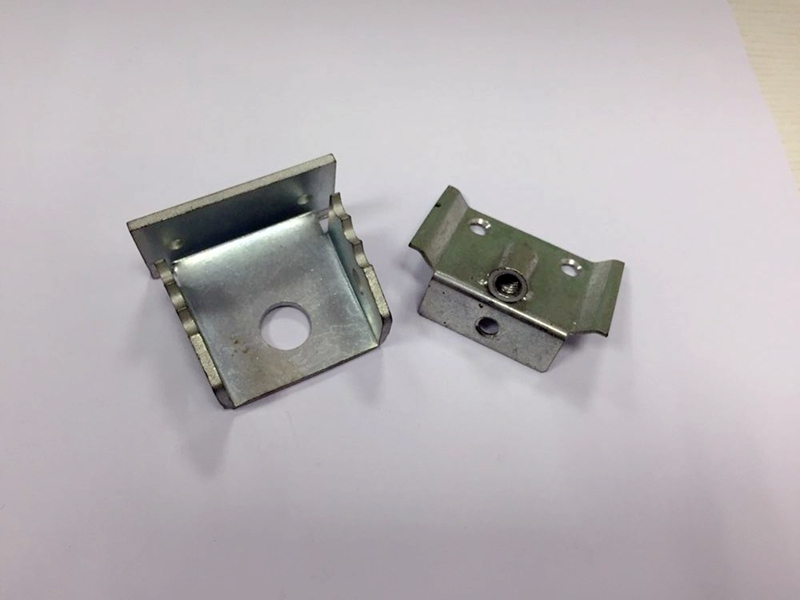

JMSP-001 |

JMSP-002 |

JMSP-003 |

|

|

|

Custom Part-Aluminum alloy guider |

|

|

|

|

JMSP-004 |

JMSP-005 |

JMSP-006 |

|

|

|

|

|

|

|

|

JMSP-007 |

JMSP-008 |

JMSP-009 |

|

|

|

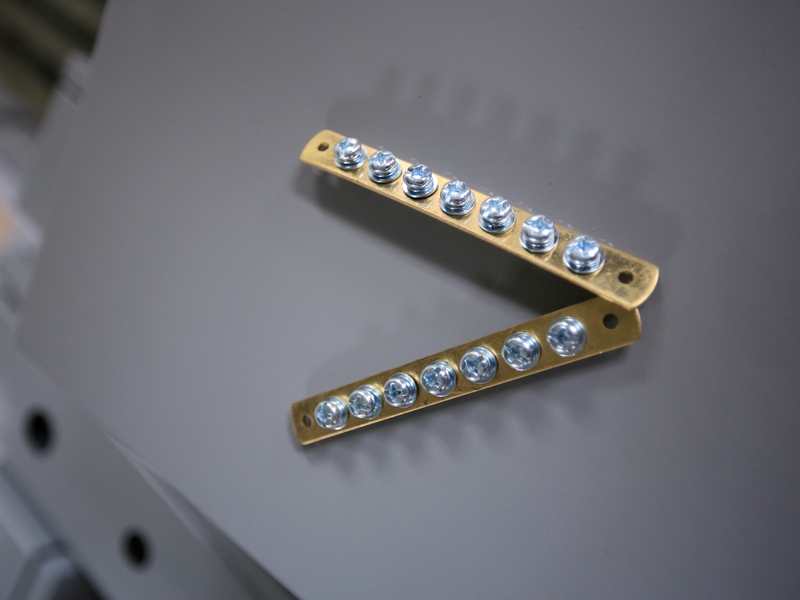

Brass Stamping parts (Hinge) |

|

|

|

|

JMSP-010 |

JMSP-011 |

JMSP-012 |

|

|

|

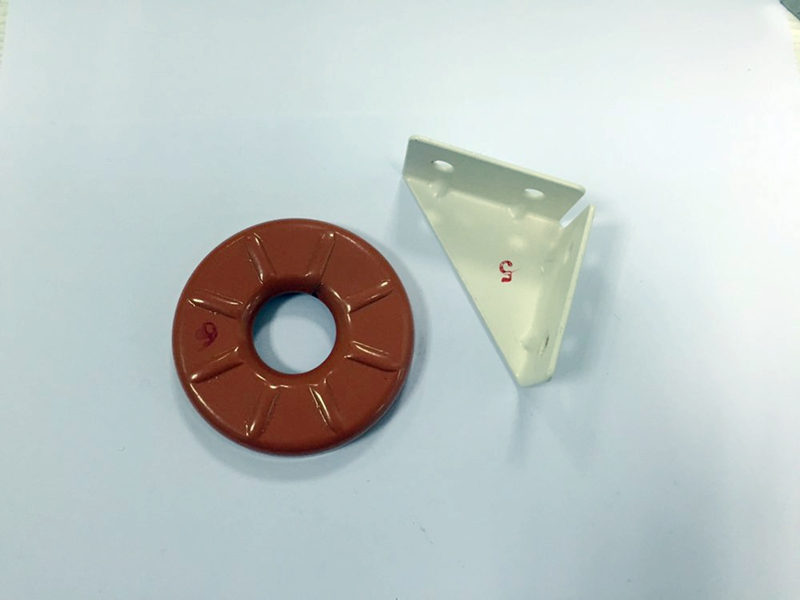

Custom washer & cup washer |

|

|

|

|

JMSP-013 |

JMSP-014 |

JMSP-015 |

|

|

|

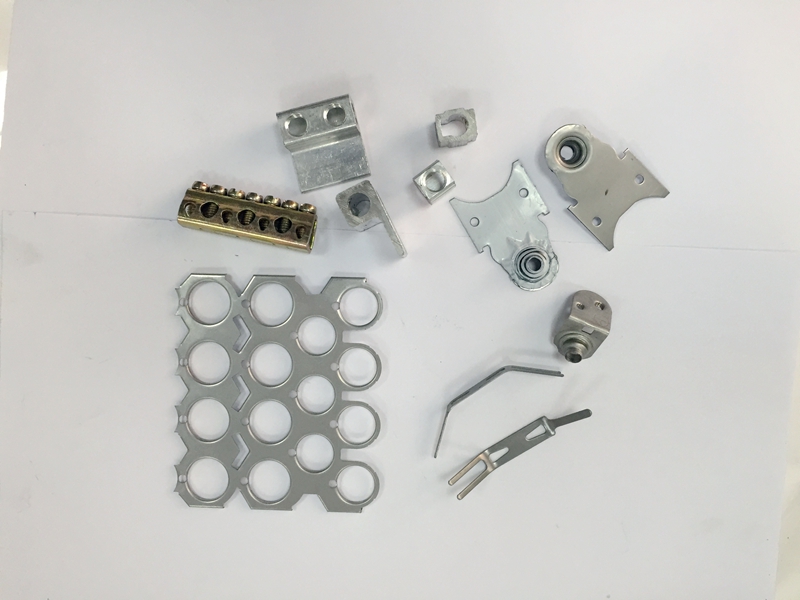

Stamping parts of water heaters |

|

|

|

|

JMSP-016 |

JMSP-017 |

JMSP-018 |

|

Aluminum Stretching stamping parts |

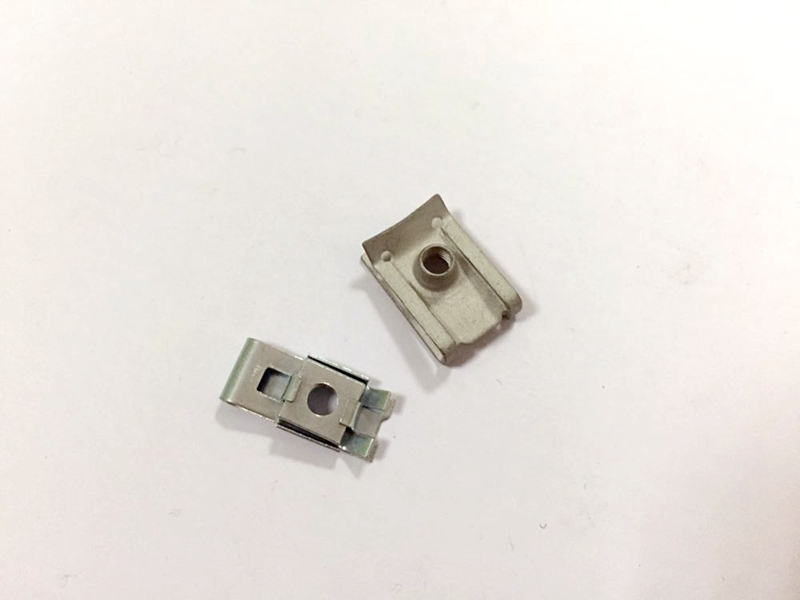

Spring Nut Clips |

|

|

|

|

|

JMSP-019 |

JMSP-020 |

JMSP-021 |

|

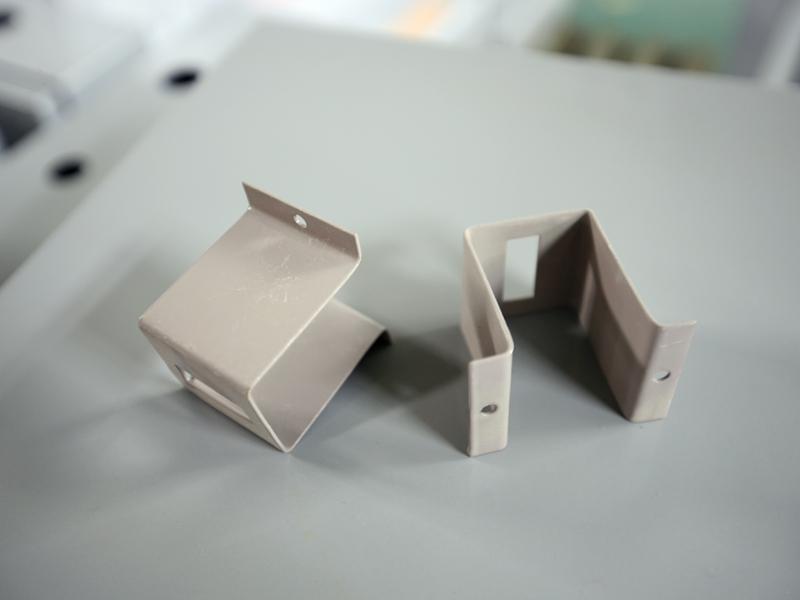

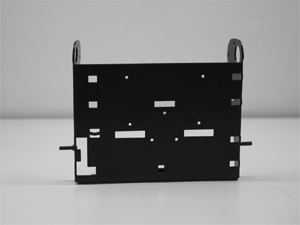

Yellowing Paint Stamping Parts |

|

Robot automatic weld stamping part |

|

|

|

|

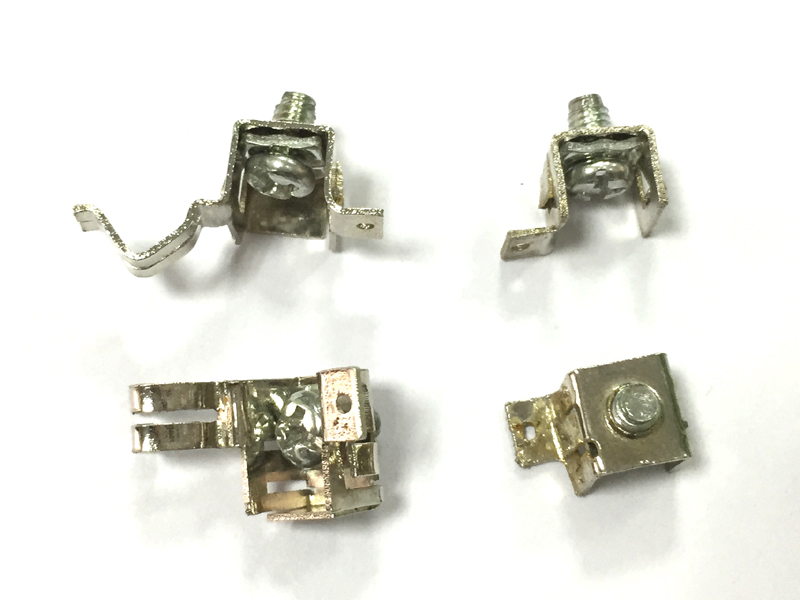

JMCAP-013 |

JMSP-014 |

JMSP-015 |

|

Electrical Contact System (Nickel-Plated Stamping Assembly Part) |

Zinc nickel alloy plated stamping parts |

GEOMET coating stamping parts |

MOQ:10000pcs

|

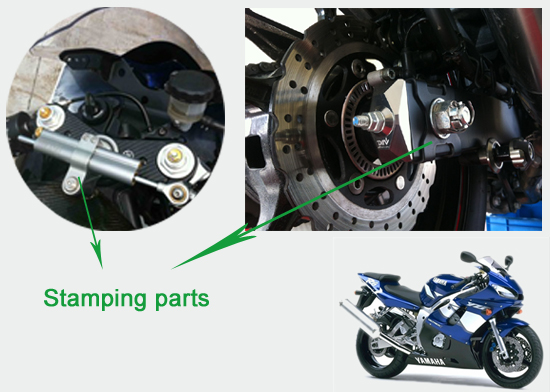

Stamping parts |

|

|

Surface Treatment: |

Blacking, polishing, anodize,geomet, chrome plating, zinc plating, nickel plating, tinting, Powder coating, spray coating |

|

Materials: |

Aluminum Alloy: |

|

5052 /6061/ 6063 / 2017 / 7075 / etc. |

|

|

Brass Alloy: |

|

|

3602 / 2604 / H59 / H62 / etc. |

|

|

Stainless Steel Alloy: |

|

|

303 / 304 / 316 / 412 / etc. |

|

|

Steel Alloy: |

|

|

Carbon Steel / Die Steel / etc. |

|

|

Other Special Materials: |

|

|

Lucite / Nylon / Bakelite / POM / PP / PE / PC / Titanium / ABS etc. |

|

|

We handle many other type of materials. Please contact us if your required material is not listed above. |

|

|

Stamping Equipment: |

TRUMPF LASER CUTTING MACHINE; |

|

CNC SHEAR MACHINE; |

|

|

CNC PUNCHING MACHINE; |

|

|

CNC BENDING MACHINE; |

|

|

TIG WELDING MACHINE; |

|

|

MIG WELDING MACHINE; |

|

|

SPOT WELDING MACHINE; |

|

|

STAMPING MACHINE; |

|

|

ROLLING MACHINE; |

|

|

PIPE BENDER; |

|

|

Mould type: |

Progressive die, single press mould, transfer mould, etc. |

|

Application: |

Aerospace, Automotive, Electrommunication, Medical, Household Appliances, Furniture industry, Machinery industry, instrument and meter |

Description of stamping process:

Stamping is an efficient production method that uses compound die, especially multi-station progressive die, to complete multiple stamping processes in a stamping machine, so as to realize full automatic production from strip material decoiling, leveling, blanking to forming and finishing.

Advantages: The stamping material has accurate and uniform thickness; smooth surface, free from spots, scars, scratches or surface cracks, etc.; uniform yield strength, without obvious directivity; high uniform elongation; low yield ratio; low processing hardenability; high production efficiency, good working conditions, and low production cost, producing hundreds of workpieces per minute generally.

|

|

|

|